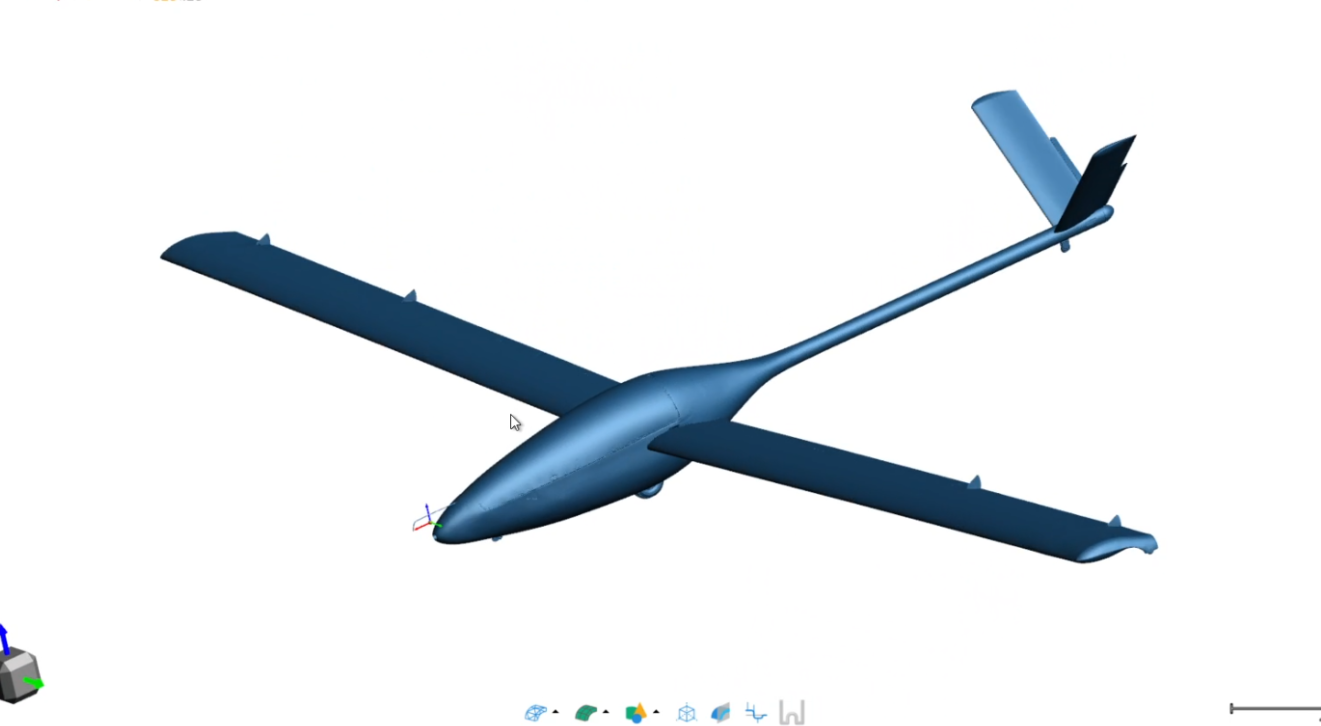

NeoMetrix Technologies specializes in a wide range of industries and applications, but one sector currently seeing significant growth is aerospace. The latest project involved scanning a 39” glider to reverse-engineer it into a 3D CAD model for further simulations and development. With aerospace trending in utilizing advanced 3D scanning and reverse engineering, NeoMetrix is at the forefront of providing next-gen solutions for these demanding needs.

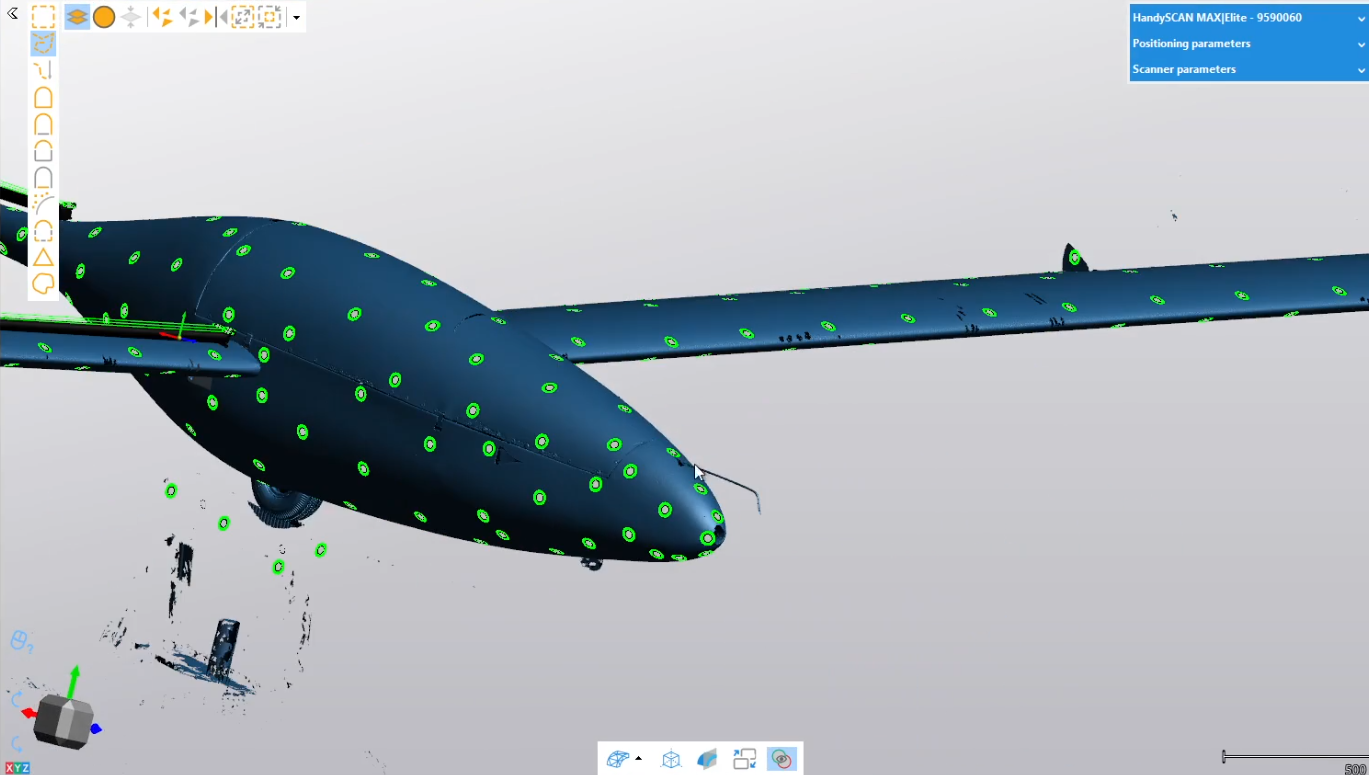

Scanning the Glider with the HandySCAN MAX Series

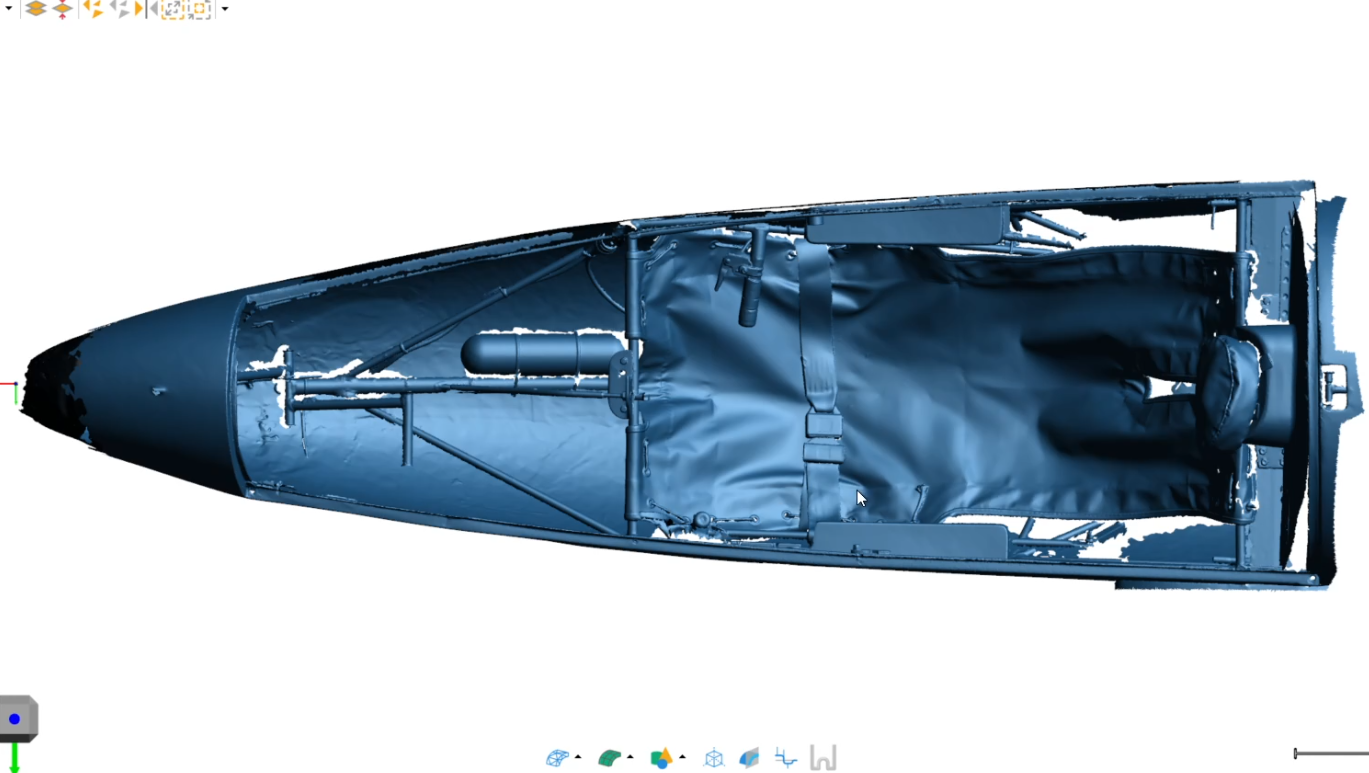

To capture every detail of the glider’s complex geometry, our engineers employed the HandySCAN MAX series. With its Flex Volume feature, we efficiently scanned the large surface area both inside and out. Despite the glider’s size, the HandySCAN MAX allowed for seamless scanning with high precision. The entire process was completed in just a few hours, demonstrating our ability to deliver quick results without compromising on quality.

Leveraging the Data for Performance Enhancements

The owner of the glider now has detailed 3D scan data that can be used to make crucial performance improvements, safety upgrades, and ensure quality assurance throughout its development. By having an accurate 3D CAD model, simulations and testing can be carried out to refine aerodynamics and structural integrity before manufacturing, saving both time and resources.

-

Component Development: The precise 3D scan enables engineers to reverse-engineer the glider, creating accurate digital models for refining and developing aerospace components with exact specifications.

-

Surface Repairs: Scanning helps identify surface imperfections or damage on existing components. The digital model allows for precise surface repairs and modifications, ensuring optimal performance.

-

Simulation-Ready Models: The detailed 3D CAD models produced from the scan are ideal for simulations, such as dynamic airflow analysis and structural testing, helping engineers predict and improve aerodynamic performance.

-

Enhanced Testing & Validation: The accurate models allow for rigorous testing and analysis in virtual environments, reducing the need for costly physical prototypes and improving the overall development cycle.

-

Streamlined Modifications: With the digital scan, engineers can quickly modify or optimize components for better performance, ensuring design flexibility and faster iteration.

Fast Turnaround – From Scan-to-CAD

One of the key advantages of our approach is the fast turnaround time. Completing a full scan of this scale in just a few hours is not only a testament to our expertise but also a critical factor for businesses that need rapid results. Once the scan was completed, our engineers quickly moved on to creating the 3D model—showcasing how reverse engineering can streamline production timelines for aerospace and other high-performance industries.

Complete 3D Scan – Ready to be reverse engineered or designed into a CAD Model

5-Star On-site 3D Scanning Experience

“Having Ricky and Kenny at the hangar felt immediately like doing business with old friends. They were incredibly friendly and felt as excited about my project as I am. They took the time to explain to me how 3D scanning works in general, then I got an in-depth look at how the HandySCAN MAX works, and why they picked it for the job. Kenny worked through scanning Freebird in no time. I was very excited to be involved by helping place the many tracking stickers around the airframe. They were also not afraid to get their hands dirty. The three of us had to lift this 300 pound, 40ft wide airplane high enough to rest onto a set of sawhorses.

I am excited to get an STL file of Freebird because it is the first of its kind for this airframe. It is a Monerai designed on paper by John Monnett in the 70’s! No computer models exist of the glider. Neometrix’s scan will help me give the world a unique opportunity to fly such a rare bird in a flight simulator. At the moment I believe there are less than 5 total Monerais flying in the world. The v-tail and small size give the Monerai a very unique flight profile that I am looking forward to programming into MSFS.

As I restore “Freebird” to airworthy condition, I will also be able to better understand the aerodynamics of the airframe. I will be able to use CFD analysis to find the limits of the airframe and make possible corrections to create a safe, fun flying airplane.”

The Advantage for Business and Operations

This process offers immense value to manufacturers and businesses across various sectors. By leveraging advanced 3D scanning technology, companies can accelerate product development, enhance quality control, and make data-driven improvements to existing designs. Whether it’s for aerospace, automotive, or industrial manufacturing, reverse engineering with the HandySCAN MAX gives companies the competitive edge they need to stay ahead in today’s market.

Take Your Projects to the Next Level with NeoMetrix

With proven expertise and state-of-the-art technology, NeoMetrix is your partner for turning complex ideas into reality. If you’re looking to optimize your product development with high-accuracy 3D scanning and reverse engineering, contact us today to learn how we can help elevate your business.

Your 3D Problems…SOLVED!

Ask us about 3D scanning services and equipment!