Additive Manufacturing Increases Deployability of Naval Vessels

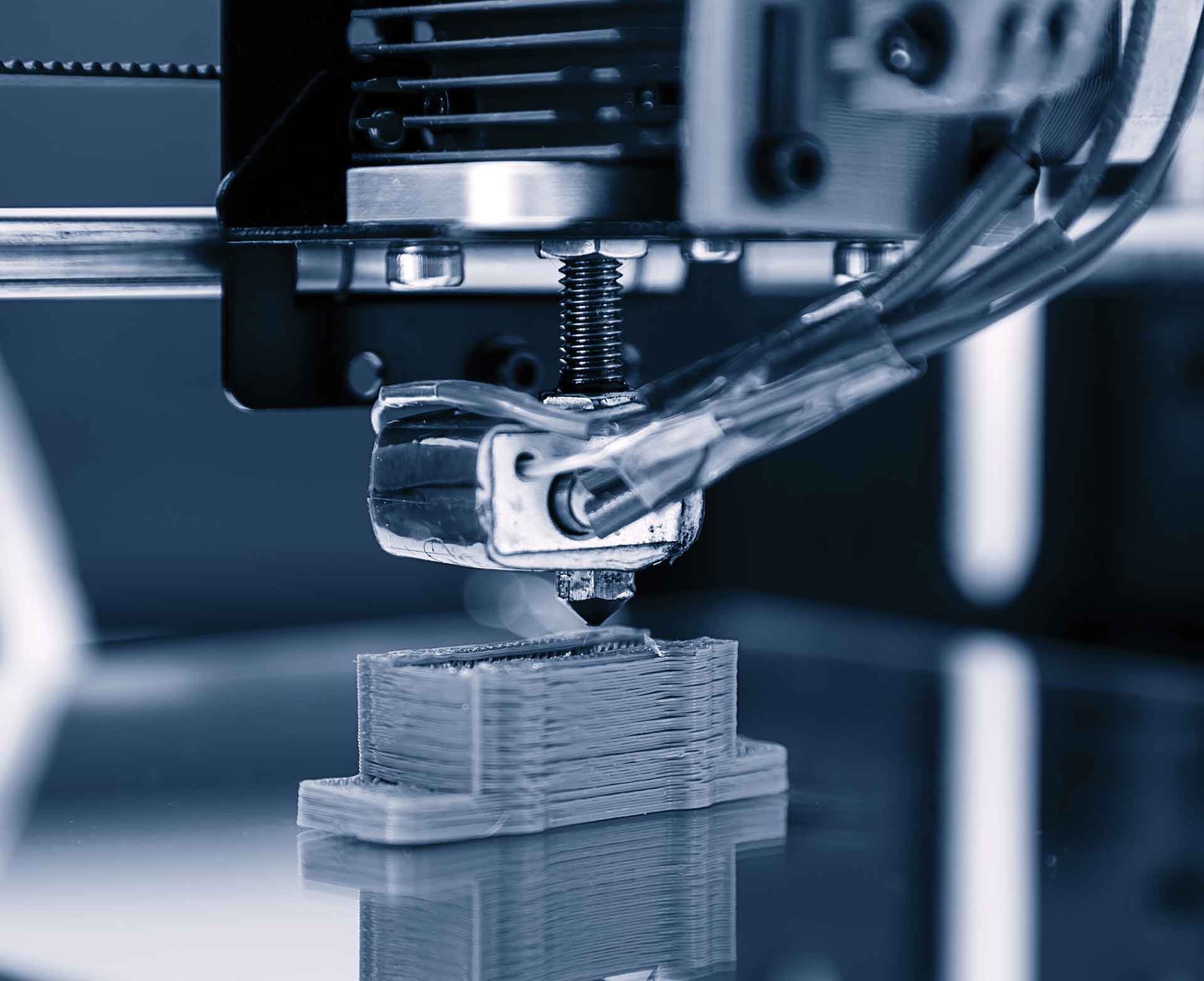

3D printing is becoming more and more a key technology for the Dutch Navy. By printing parts on board of frigates, they will be less dependent of complex logistic operations. The latest development is the AMCOD, a mobile repair centre integrated in a standard shipping container. Within an hour after installation anywhere in the world, defense units can start 3D printing polymer parts. The INTAMSYS FUNMAT PRO 410 3D printer is used to print replacement parts that are subjected to both mechanical and thermal stress. When a Dutch naval vessel leaves the port of Den Helder, one hour above Amsterdam, on a mission, there are about 30,000 spare parts on board. These are needed to keep the ship operational during the time the mission lasts. These parts vary from high-quality engine parts to covers for the shower drain, protective covers for rockets to weed filters for cold water makers.

3D printing is becoming more and more a key technology for the Dutch Navy. By printing parts on board of frigates, they will be less dependent of complex logistic operations. The latest development is the AMCOD, a mobile repair centre integrated in a standard shipping container. Within an hour after installation anywhere in the world, defense units can start 3D printing polymer parts. The INTAMSYS FUNMAT PRO 410 3D printer is used to print replacement parts that are subjected to both mechanical and thermal stress. When a Dutch naval vessel leaves the port of Den Helder, one hour above Amsterdam, on a mission, there are about 30,000 spare parts on board. These are needed to keep the ship operational during the time the mission lasts. These parts vary from high-quality engine parts to covers for the shower drain, protective covers for rockets to weed filters for cold water makers.

“If we could print ten percent of those 30,000 parts, we will reduce our logistics footprint dramatically,” says Max Nijpels, who works at the Expertise Centre Additive Manufacturing (ECAM), an innovation lab within the Directie Materiële Instandhouding (DMI), the maintenance department of the Royal Dutch Navy.

“If we can replace that ten percent with a 3D printer and a few rolls of filament, we will save storage space, weight and logistical handling. At the same time additive manufacturing enables us to increase operational deployability”.

Higher Quality Replacement Parts

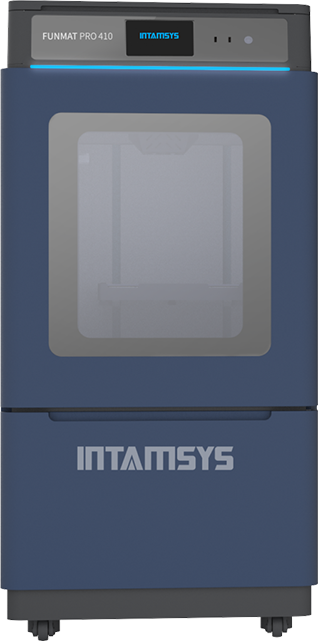

MARAMEX, the internal naval platform for the exchange of 3D files, printer settings and descriptions, already contains several hundred components that have been tested and validated. The ECAM-trained naval personnel on board can reverse engineer parts themselves if they are not for download available on the “Thingiverse of the Navy”. So far, these are non-critical parts, for which PLA as a material is sufficient. ECAM now wants to go a step further. That is why it has invested in three High Temperature capable 3D printers from INTAMSYS: one FUNMAT HT, the entry level model, and two of the FUNMAT Pro 410, the industrial version. Max Nijpels: “We want to print replacement parts that can be used in, for example, the engine compartment, where the temperature can rise sharply. Or in applications in which the part is subjected to heavier mechanical stress”. This requires 3D printing with advanced polymers such as Polycarbonate, PEKK and PEEK and nylon filled with carbon fibres. The three INTAMSYS FUNMAT printers were purchased for this purpose. “These will work together with the standard FFF printers. Where they fail in terms of printing material, we will use the new 3D printers”.

An ULTEM part printed by the Dutch Navy’s FUNMAT PRO 410

A PPSU part printed by the Dutch Navy’s FUNMAT PRO 410

Stable Print Results

For the Dutch Navy, three factors were important when selecting a high-temperature 3D printer: open platform; free choice of materials, and just as easy to operate as a standard FFF printer for PLA, with a reliable result.

Max Nijpels: “The INTAMSYS 3D printers allow us to print with Polycarbonate or PEKK just as easily as with PLA, thanks to the build chamber being heated to 90 degrees. The printer manufacturer has found the right balance in terms of temperature control so that the temperature is high enough to prevent warping and sufficient cooling to ensure good adhesion of the layers and to prevent the part from collapsing due to overheating”.

Openness Needed for Process Certification

The open platform of the INTAMSYS High Temperature capable 3D printers is another crucial criterion for the Dutch Navy. The printer manufacturer offers customers to use validated filaments from major manufacturers, but they can also select filaments from different brands and develop their own settings. INTAMSYS offers this free choice of material because the user can set all the parameters himself in the 3D printer. Once these are fixed, or the navy adopts the profile of one of INTAMSYS’ partners, 3D printing with these high-quality polymers is just as easy as with PLA. This turned out to be a perfict fit in a field everything revolves around operational

usability.

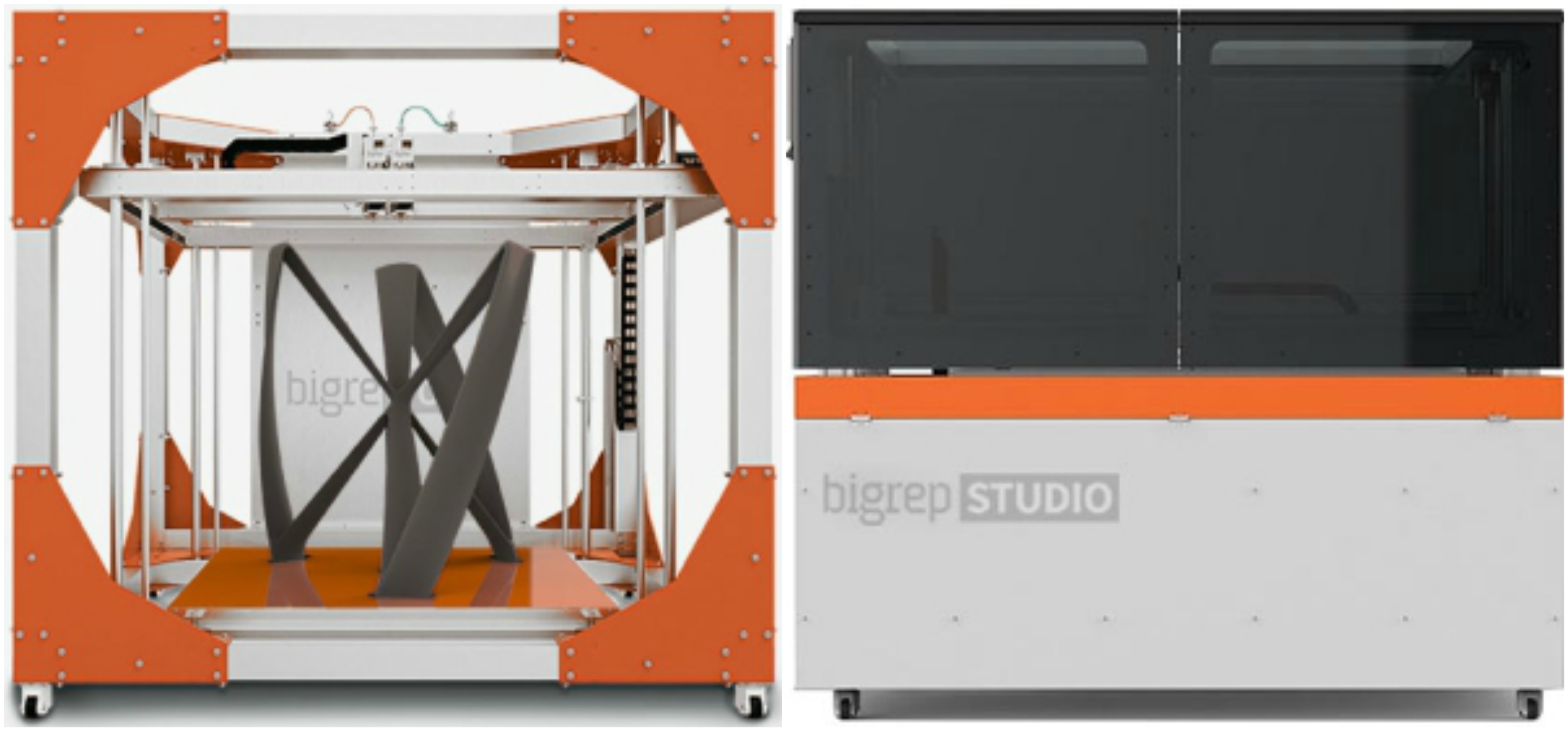

AM-Container

In order to be even less dependent on logistic supply chains, ECAM has developed the AMCOD for all defense units in The Netherlands: Additive Manufacturing Container for Defence. This contains the INTAMSYS PRO 410, the industrial High Temperature Capable 3D printer, which includes a filament bay with cooling and drying and double print heads. In a shipping container, equipped with air conditioning, ventilation, and a UPS to prevent fluctuations in the peak load of the generator disturbing the 3D printers, two CAD workstations have been created and there are three FFF printers, including the INTAMSYS PRO 410. The AMCOD can be installed and be operational within an hour. In this way, the Marine Corps on mission anywhere in the world is no longer dependent on complex logistical supply lines, but can print its own spare parts, which can be used immediately thanks to the robust printing process of the INTAMSYS printers.

- PEEK

- PEEK-CF

- PEKK

- ULTEM

- PPSU

- PA

- PA-CF

- PC

- ABS

High Performance Funtional 3D Printers & Materials Now Available through NeoMetrix!