When it comes to manufacturing components and leading cutting edge technology, Markforged has the most reliable and high-quality 3D printing systems available.

In the 3D application below, it is obvious how a system like the Markforged Metal X can be an extremely valuable asset in the manufacturing industry cutting time, costs, and delivering high-performance 3D prints. In this case, being able to reproduce a part from a classic car called a solex carburetor, which happens to be made of metal, and no longer manufactured.

Watch the video HERE to learn more!

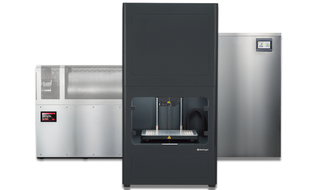

Markforged Metal X

The Metal X 3D Printing system is an end-to-end manufacturing solution, providing users everything you need to go from design to fully functional parts in less than a day. The Metal X is up to 10x less expensive than alternative metal additive manufacturing technologies — and up to a 100x less than traditional fabrication technologies like machining or casting. Markforged’s cloud-based printer management software, built-in touchscreen interface and automatic material tracking make the Metal X system the simplest way to manufacture metal parts.

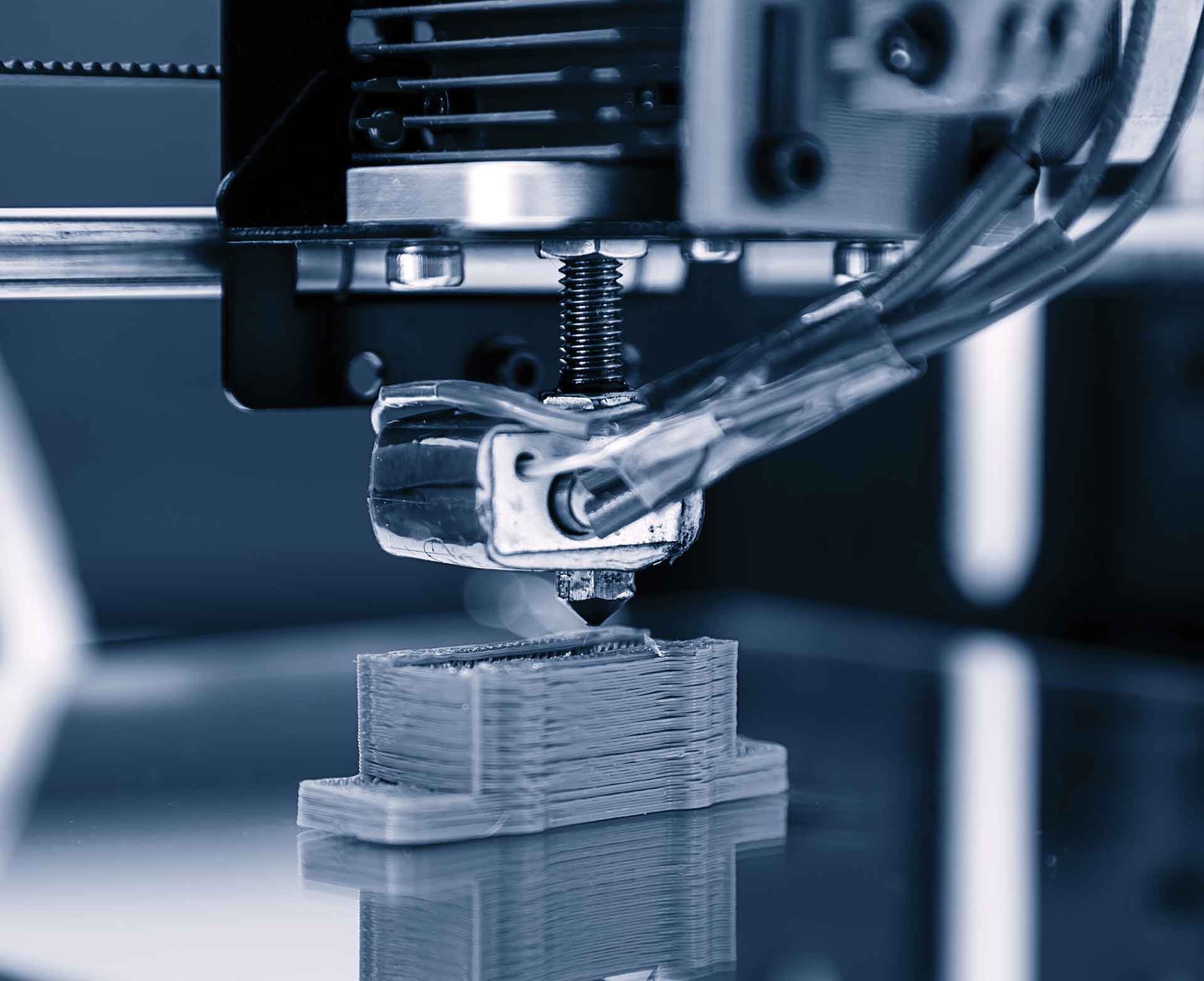

Atomic Diffusion Additive Manufacturing (ADAM) Technology

- Design: CAD your part, upload the STL, and select from a wide range of metals. The Eiger software does the rest making printing the right part easy.

- Print: Metal powder bound in plastic is printed a layer at a time into the shape of your part. Parts are scaled up to compensate for shrinkage during the sintering process.

- Sinter: Printed parts go through a washing stage to remove some of the binder. They are then sintered in a furnace and the metal powder fuses into solid metal.

- Part: Pure metal and up to 99.7% dense, the final parts are ready for use. They can be processed and treated just like any other metal parts.