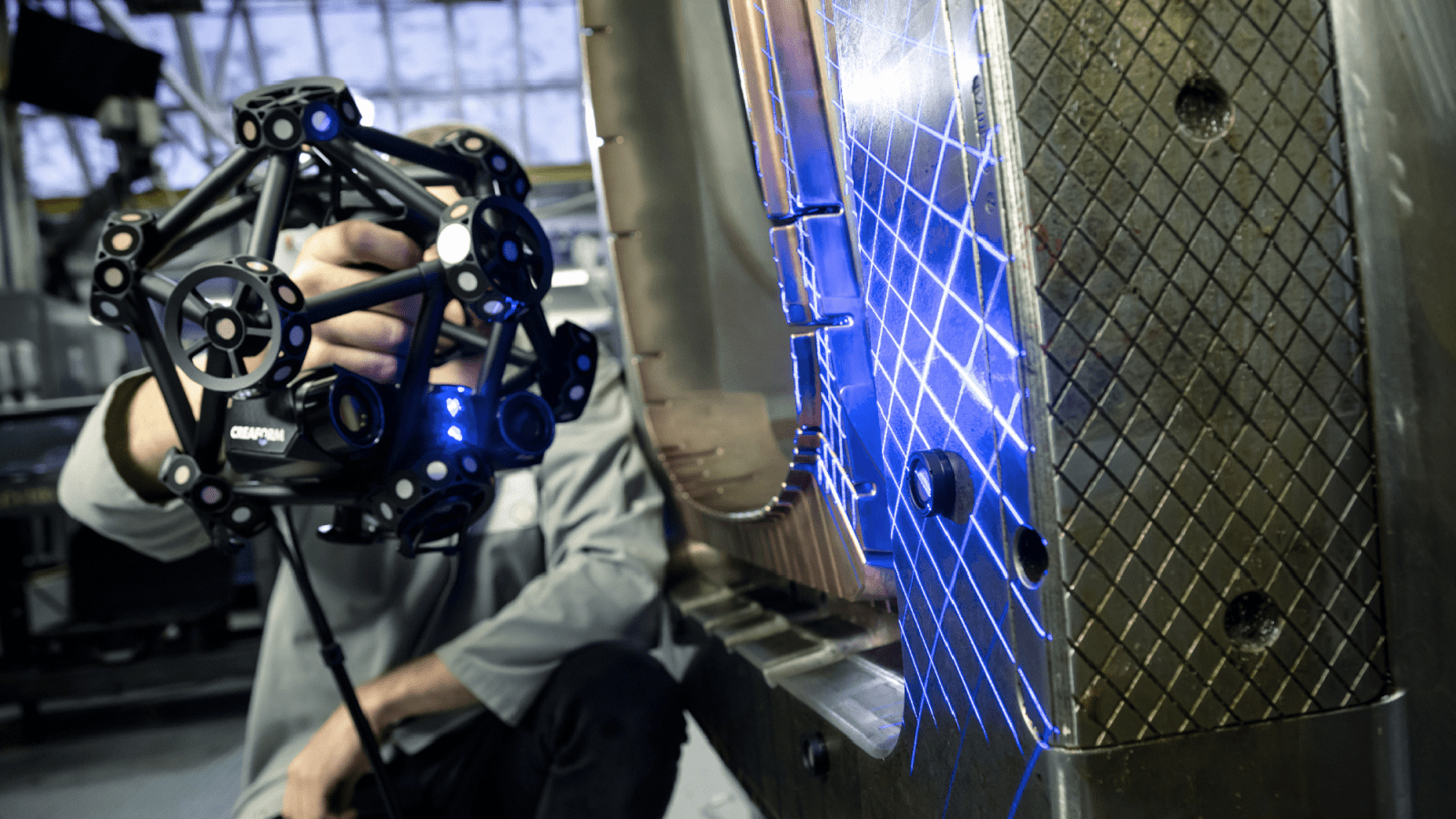

3D scanning is a hot new technology that will change the way we do business forever. It has been employed in everything from measuring and surveying, quality control for industrial companies or even designing products! There are so many ways you can use 3d scanners to your advantage- depending on what kind of business it is depends which method might work best with their needs.

Get Started Today!

3D scanning is a powerful tool for industrial companies that can be used in many areas of the business. We’ll go over some reasons it may make sense and show you what parts your factory might want to use this technology with!

Makes Designing More Accurate and Efficient

The design process often takes longer than expected due to the time it takes for calculations. We can significantly reduce this delay by implementing 3D technologies in our designs, which allow us not only see what we’re making before finalizing production but also optimize its size and shape so that everything moves more efficiently during manufacturing!

3D scanning is a game-changer for designers and craftspeople alike. Instead of relying on humans to make accurate measurements or alterations, this technology can be used in the design process itself, and get efficient results! This means faster turnaround times as well: instead taking hours upon endless amounts of time while measuring things out by hand, now all types of surface data can be captured in very little time.

Faster Prototyping Process and Simple Repeatability

When you’re in the prototype phase of creating products, these prototypes will likely have to go through multiple iterations. If you’re using 3D scanning, you may expedite the process. 3D scanning will likely reduce the number of iterations necessary through the production and prototyping phase.

Scanners can help measure cross-sections and identify what parts of the design are warped. They can also store important data related to the item after it is scanned. This will help down the track when changes need to be made. 3D scanners can double the speed required compared to the conventional prototyping process.

Ensures Quality and Accuracy

One of the best reasons to implement 3D scanning technology in your industrial business today is improved quality control. In the past, we had to rely on inadequate methods of measuring and testing product specifications. But now, with 3D scanning technology, it’s possible to be incredibly detailed without measurements.

This attention to detail and extreme accuracy in measurements will improve the quality of your products tenfold. These technologies can measure the volume of objects and the material and scale within millimetres of detail. Using this detail, the scanner relays information to the CAD software, where it can detect even the slightest imperfections with complete accuracy.

Scanners can help measure cross-sections and identify what parts of the design are warped. They can also store important data related to the item after it is scanned. This will help down the track when changes need to be made. 3D scanners can double the speed required compared to the conventional prototyping process.

Takeaways

Not only is 3D technology exciting and innovative, but it’s also beneficial. The kind of 3D scanning and printing capacities that we will see in the coming years will have the ability to transform society into places we could only dream of. Precise technology will propel industrial companies to the next level, while those not using it may fall behind.

If you’re in an industrial company, you should take on board these technologies as soon as possible because you will be left behind if you don’t. As industry leaders, the best thing we can do is constantly look for ways to improve. One of the ways to do this is to be on the cutting edge of science.

If you want to embrace technology and if you want to remove many obstacles, no matter the industry you are in, you should consider 3D scanning. Starting from product development, up to planning and manufacturing, you will benefit from these devices greatly. They are easy to use and implement, and you will see how much time and resources they are saving you. Let your employees focus on the more important parts of their tasks and give them the tools they need to advance.

Original article – https://thebossmagazine.com/3d-printing-technology/