In advanced manufacturing environments, speed is important — but control is everything.

Integrating a large-format 3D printer into your production workflow isn’t just about making bigger prototypes. It’s about unlocking a new level of agility: producing full-scale prototypes, functional end-use parts, tooling, housings, and fixtures — all in-house, on demand.

For engineers and manufacturers, large-format additive manufacturing bridges the gap between prototyping and production without the cost and rigidity of traditional tooling.

From Prototype to Production — Without Changing Platforms

From Prototype to Production — Without Changing Platforms

Key integration advantages of BigRep 3D Printers:

-

Large-scale build volume for full-size functional components

-

Closed, insulated build chamber for material stability and compliance

-

Industrial air filtration for safe operation

-

Remote monitoring via BigRep CONNECT for production visibility

-

Engineering-grade materials like HI-TEMP for rigid, accurate parts

This makes it possible to move from prototype validation directly into low-volume production without investing in molds or tooling.

THINK BIG.

Proof of Scale: Full-Size Automotive Applications

Large-format additive manufacturing isn’t limited to enclosures. A full-scale Porsche Cayman bumper has been printed using the BigRep STUDIO G2 — demonstrating the ability to produce automotive-scale structural components.

This level of scale allows manufacturers to:

-

Validate full assemblies before tooling

-

Produce custom low-volume components

-

Create jigs and fixtures at production size

-

Replace discontinued or hard-to-source parts

Real-World Story: AFYS3G Cuts Lead Time from Months to Days

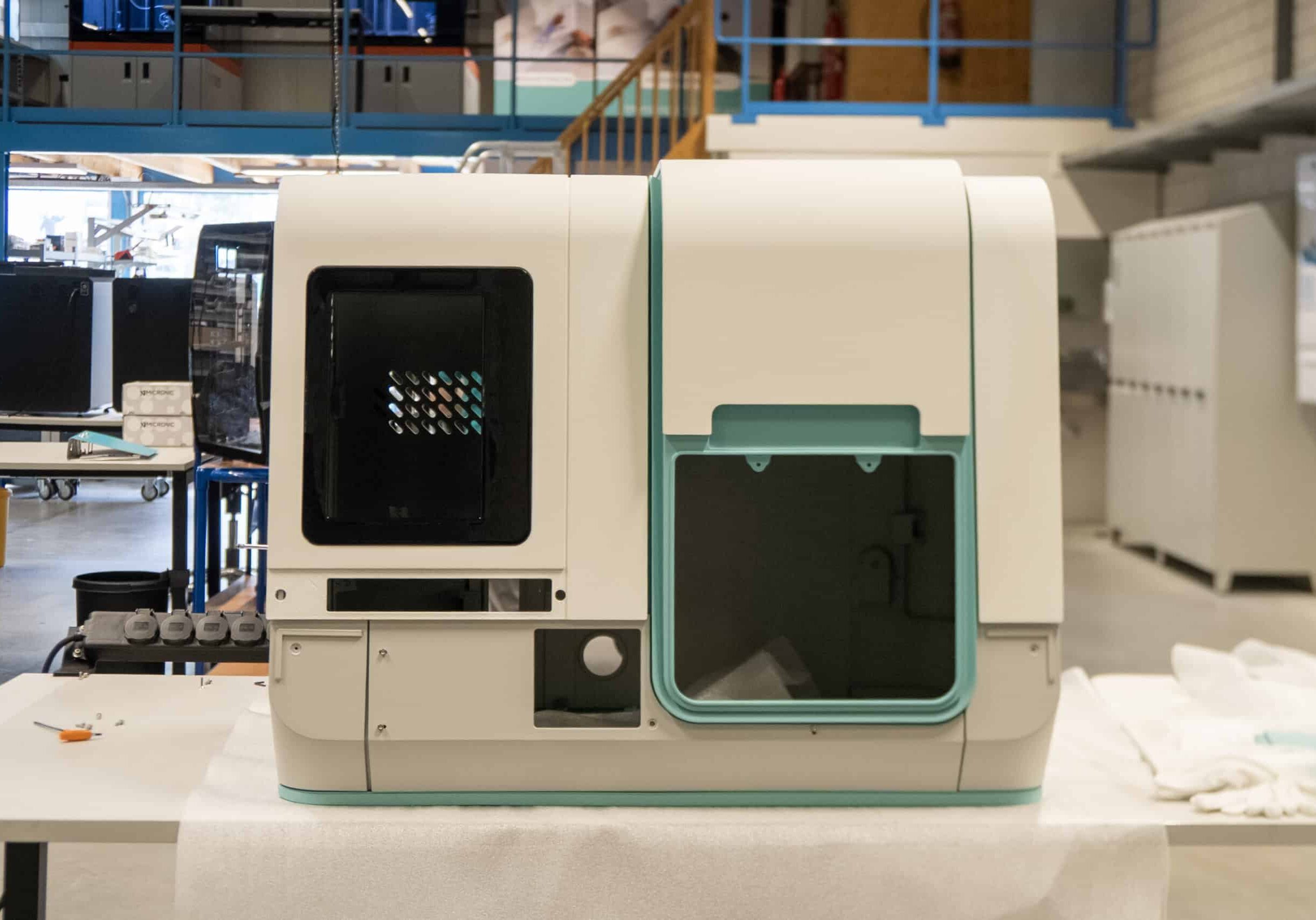

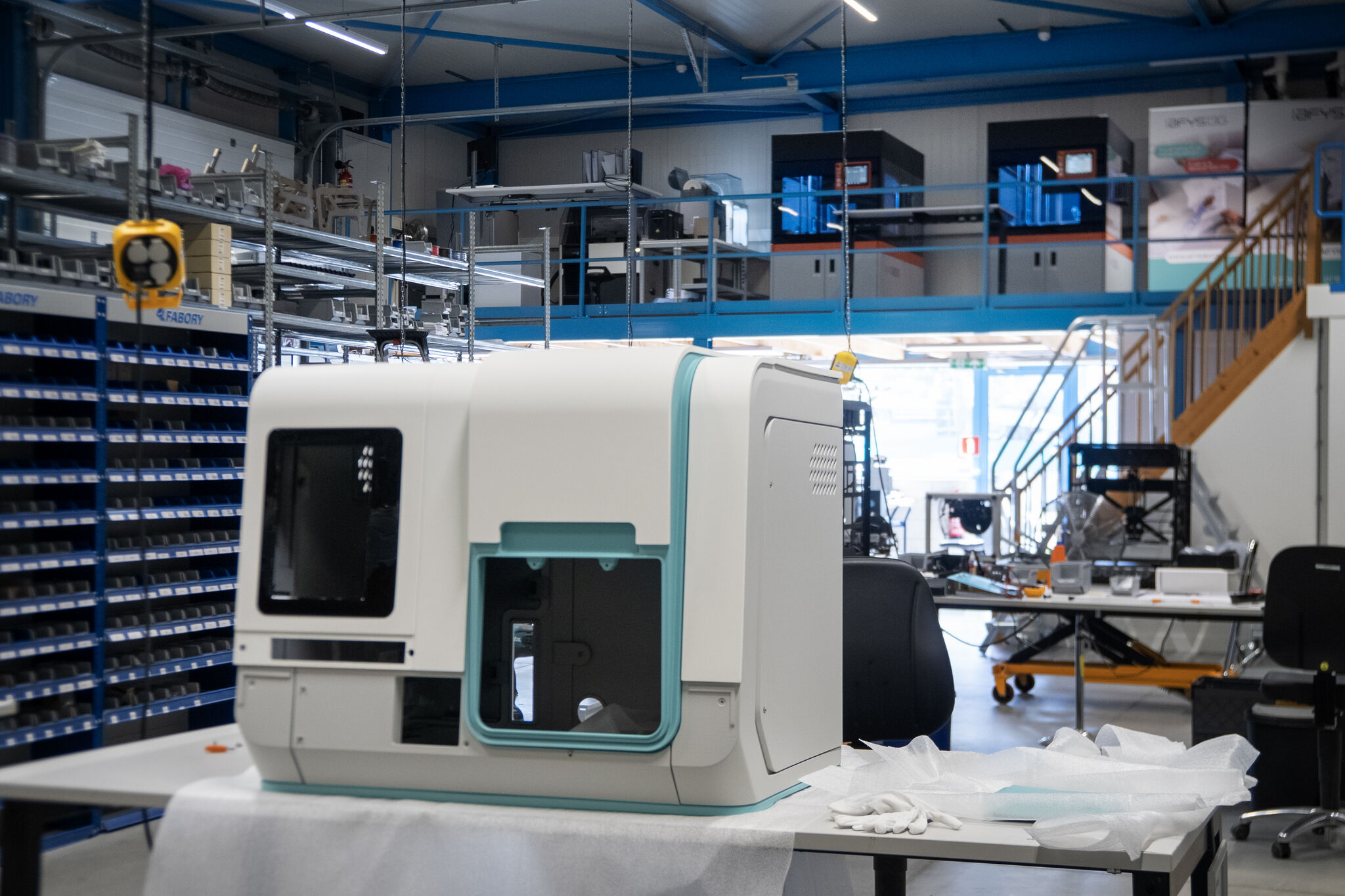

Netherlands-based AFYS3G specializes in lab devices for the life science industry — equipment that marks, scans, thaws, mixes, and manages biological samples.

In an industry where change is constant and speed matters, traditional manufacturing methods created bottlenecks. Tooling costs, outsourcing delays, and long lead times slowed innovation.

Using materials like HI-TEMP, they achieved rigid, warp-resistant parts that, after finishing, are indistinguishable from injection-molded components — while maintaining the mechanical integrity required for lab environments.

The impact? Demand increased so rapidly they invested in a second STUDIO system to eliminate production bottlenecks.

By integrating the BigRep STUDIO, AFYS3G was able to:

-

Produce large equipment housings in-house

-

Maintain high dimensional accuracy

-

Achieve surface finishes suitable for post-processing

-

Reduce lead times from months to days

-

Avoid mold investment costs entirely