Infinite Possibilities

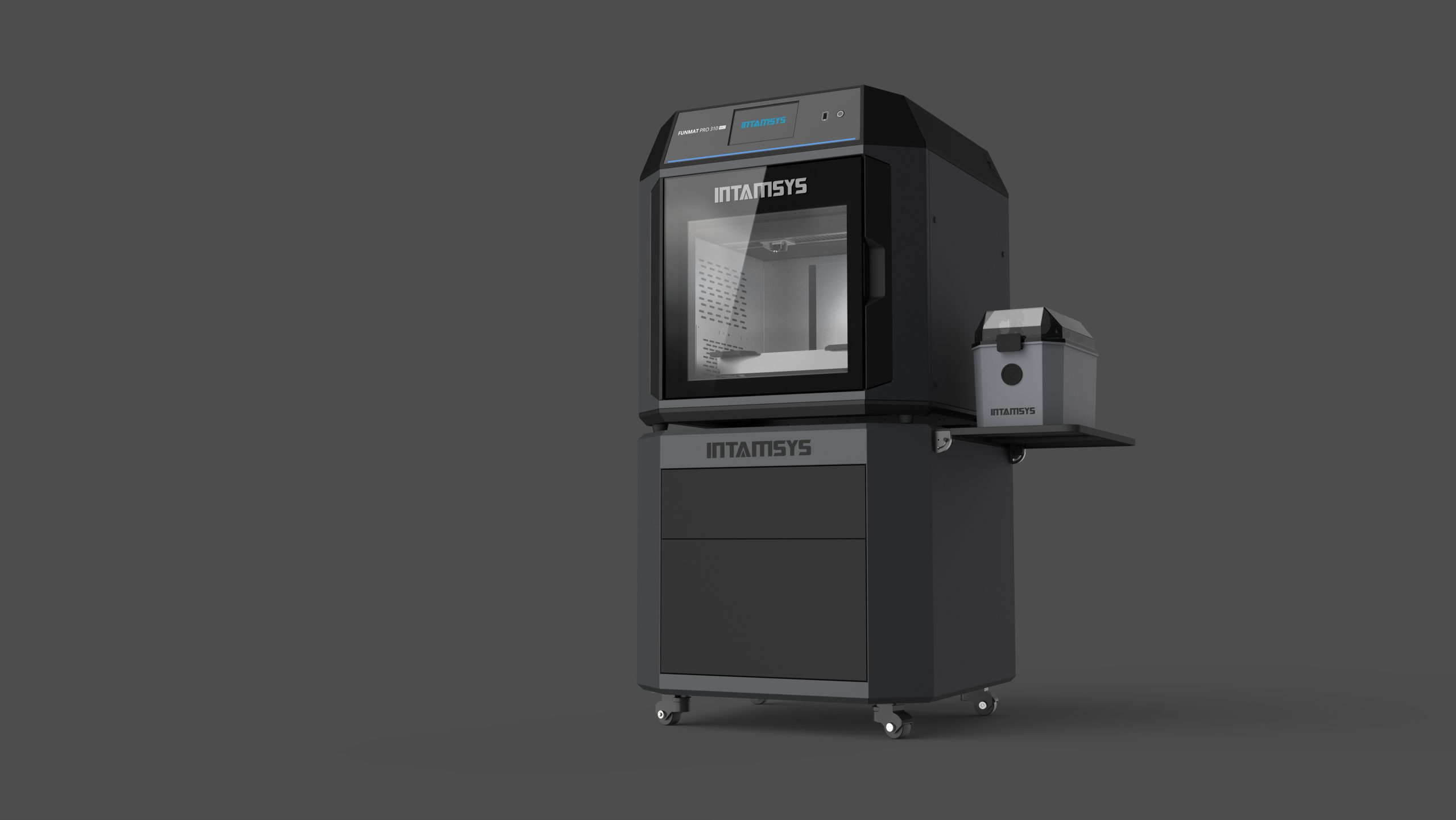

The INTAMSYS FUNMAT PRO 310 NEO stands out as a beacon of innovation in additive manufacturing. One of its latest advancements is the ability to print parts in Thermoplastic Polyurethane (TPU), which is opening new doors for various industries and applications. Let’s explore TPU’s characteristics, functions, and how it’s transforming industries before we explain how to easily acquire this next-gen desktop 3D printer from NeoMetrix.

Characteristics and Functions of TPU

Thermoplastic Polyurethane (TPU) is a versatile material known for its unique combination of elasticity, transparency, and resistance to oil, grease, and abrasion. Here are some key characteristics that make TPU a standout choice:

- Flexibility and Elasticity: TPU maintains a rubber-like flexibility, making it ideal for producing parts that require bending, stretching, or compressing without losing their original shape.

- Durability: It offers excellent wear and tear resistance, ensuring long-lasting performance in demanding applications.

- Chemical Resistance: TPU is resistant to oils, greases, and various chemicals, which enhances its usability in harsh environments.

- Shore Hardness Range: Available in various hardness levels, TPU can be tailored to specific needs, from soft, flexible applications to more rigid uses.

TPU is an invaluable material for creating functional prototypes, end-use parts, and everything in between.

Learn How TPU Overcomes Industrial Challenges

Thanks to its remarkable properties, TPU is widely used across several industries. Here’s a look at where TPU is making significant impacts:

AUTOMOTIVE

TPU’s flexibility and durability are leveraged for parts such as air ducts, protective covers, and sealing components. Its resistance to chemicals and wear makes it ideal for under-the-hood applications.

CONSUMER PRODUCT & ELECTRONICS

From phone cases, and electronic enclosures, to wearable bands, TPU’s comfort and durability are prized in everyday products.

HEALTHCARE & MEDICAL

The biocompatibility of TPU allows for its use in medical devices, prosthetics, and orthotics, where flexibility and patient comfort are crucial.

Our team at NeoMetrix is ready to help you integrate the FUNMAT PRO 310 NEO into your operations with ease.

Key Features

| Build volume | ( 305 mm x 260 mm x 260 mm) |

| Print speed | 120 mm/s max. |

| Extruder | IDEX Dual Extruders |

| Certified materials | PC, PC-ABS, PA6/66, PA66-CF, PA12-CF, ABS, ABS+, SP3030, ASA, PLA, HIPS, PVA, ESD-safe, NOW PRINTS TPU |