ADVANCED 3D SOLUTIONS FOR THE MINING INDUSTRY

HIGH-ACCURACY 3D SCANNING | LARGE-SCALE 3D PRINTING | PROTOTYPE AND END-USE PARTS

Mining for Oil, Gas, and Resources

Mining industries face unique challenges that demand cutting-edge solutions for inspection, maintenance, and manufacturing.

Utilize our advanced technology to stay ahead in the mining industry, ensuring safety, efficiency, and precision in every project. Contact NeoMetrix Technologies today to learn more about our innovative solutions for mining operations.

ADVANCED INDUSTRIAL SOLUTIONS

-

Minimized Downtime: Detect equipment defects early to prevent costly delays.

-

Large-Scale Part Production: Manufacture durable, high-precision parts

-

Increased Efficiency: Improve operational timelines with fast and reliable data.

-

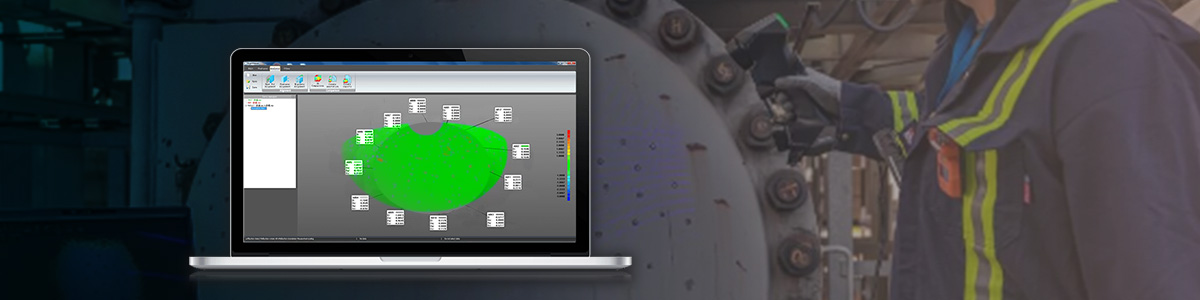

Precise Underground Mapping: Quickly and accurately map tunnels and hazardous sites.

-

Enhanced Risk Management: Monitor and manage aging infrastructure with detailed, traceable data.

3D SCAN-TO-CAD SOLUTIONS

REVERSE ENGINEERING & 3D MODELING

INSPECTION & QUALITY CONTROL

3D PRINTING & RAPID PROTOYPING

We’ve got you covered.

Speak with our experts today!

EQUIPMENT • SERVICES • SOLUTIONS

Applications in Mining & Heavy Industies

- Prototyping: Test-fit designs before final production.

Functional Replacement Parts: Ensure durability and reliability. - Jigs, Fixtures, and Tooling: Enhance and speed up manufacturing processes.

- Semi-Structural Components: Produce brackets, clips, and similar parts.

- Heavy-Duty and Electrical Enclosures: Create durable housing solutions.velop robust energy storage solutions.

- Rugged Enclosures: Protect sensitive equipment.

- Mine Site Weather Stations: Produce reliable weather monitoring equipment.

- Pipes: Inspect and analyze pipeline integrity to prevent failures and ensure continuous operation.

- Heavy-Duty Machinery: Utilize 3D scanning to assess wear and tear, optimize maintenance schedules, and extend the lifespan of machinery.

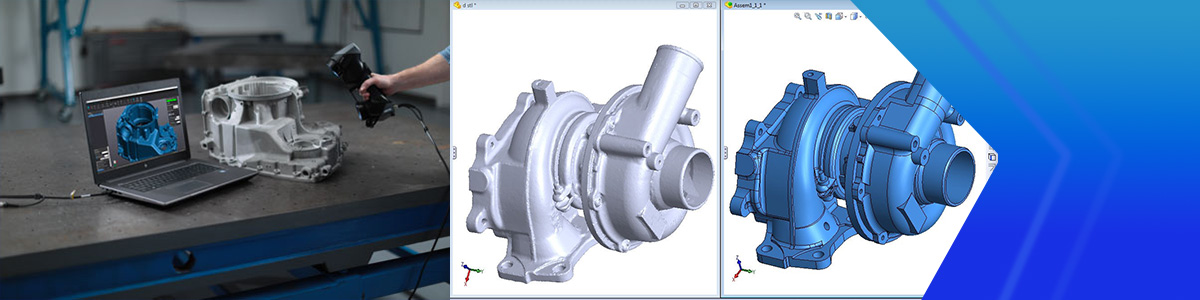

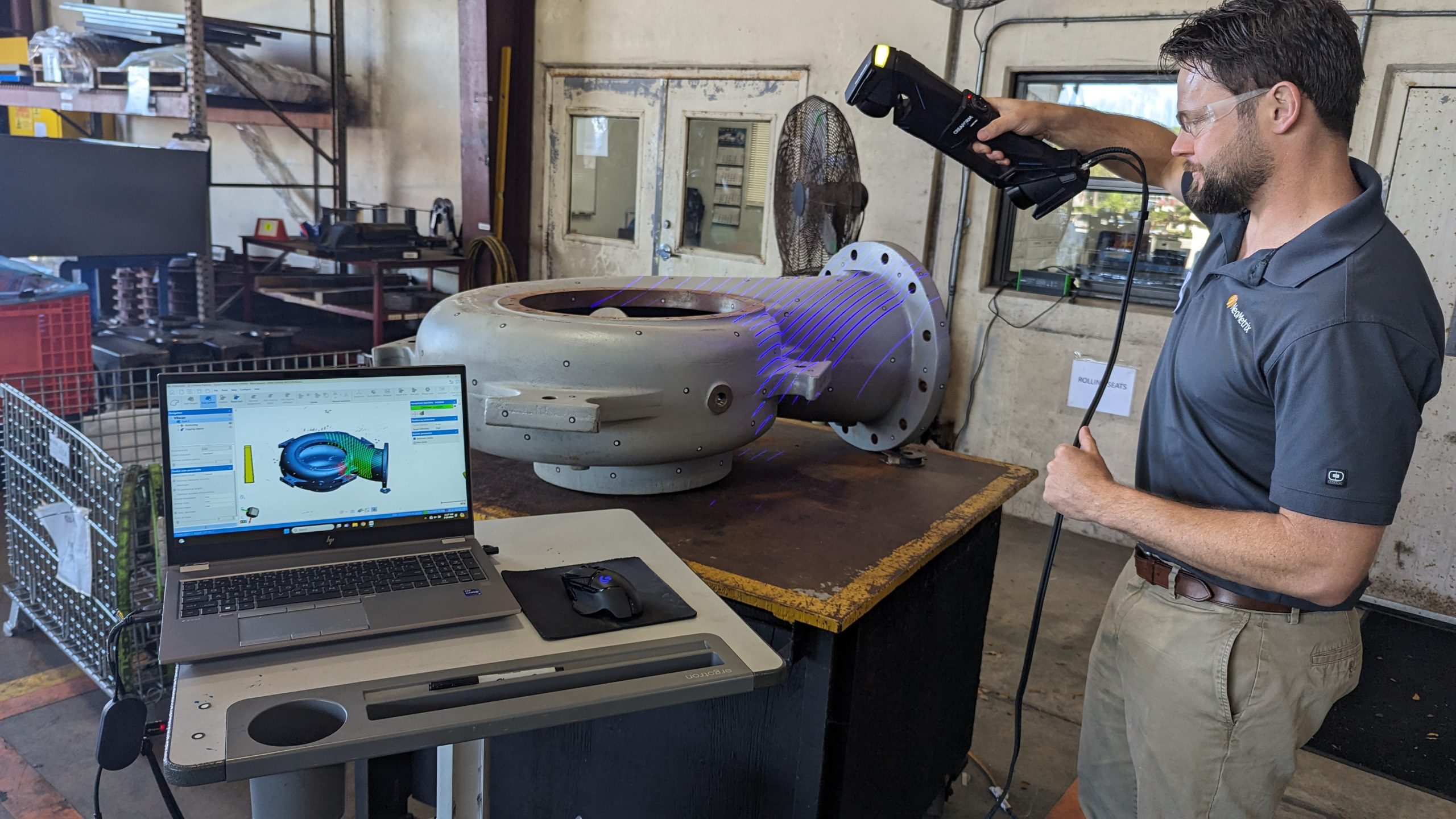

- Volutes and Pumps: Reverse engineer complex components to create accurate, high-quality replacements or upgrades.

3D Scanning and 3D Printing technology is revolutionizing modern mining operations by providing faster and higher-resolution parts and data than traditional methods.

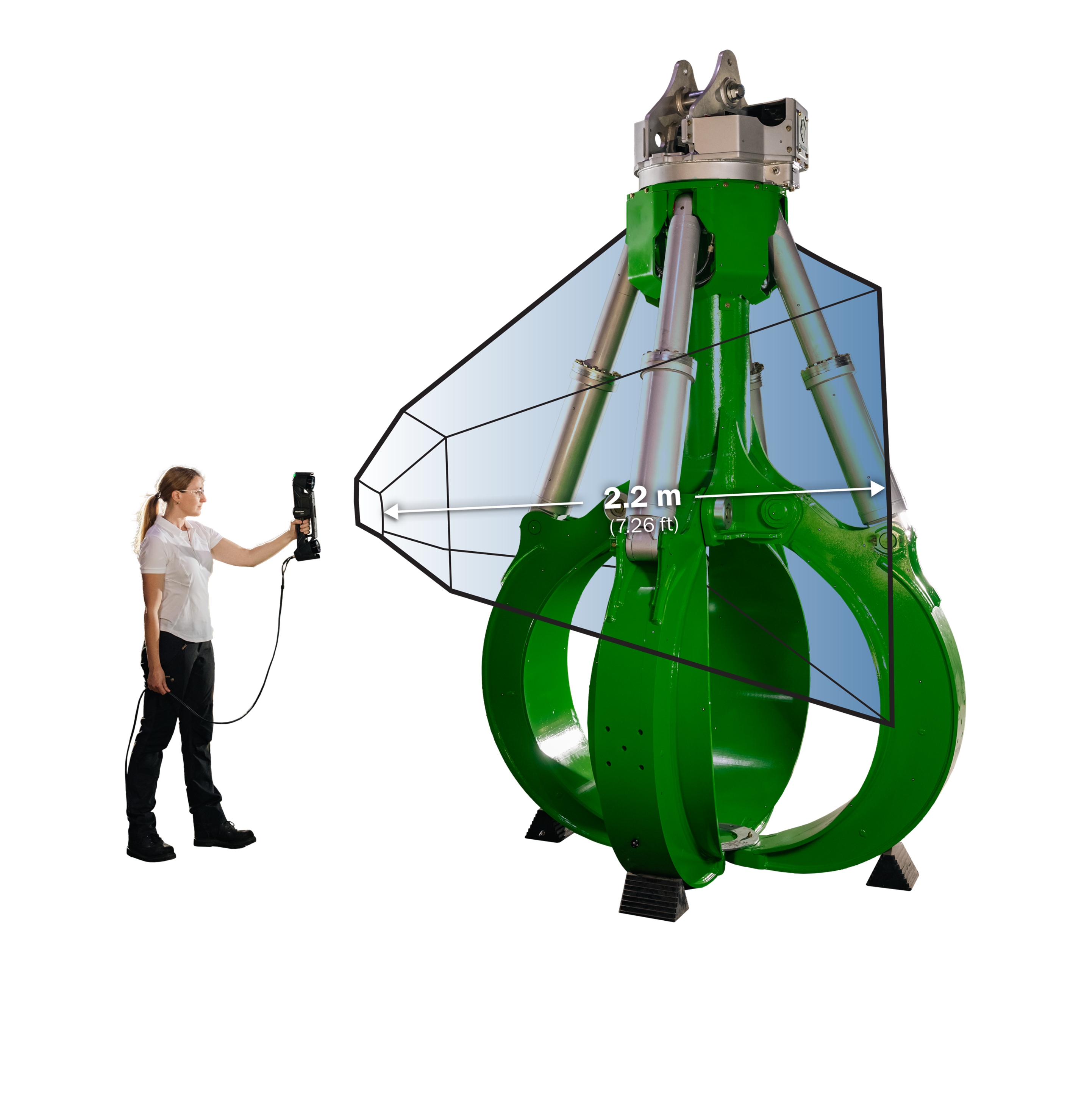

3D Scanning is a powerful tool specializing in addressing key challenges, such as underground mapping, managing hazardous sites, and minimizing equipment downtime, thereby enhancing operational efficiency and meeting tight project timelines.

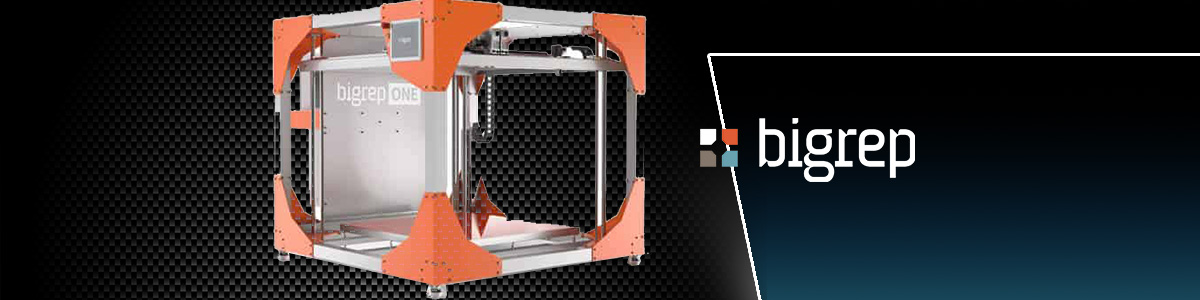

FDM 3D printing materials, including PRO HT, offer unique properties such as transparency, biocompatibility, FST certification, chemical resistance, heat resistance, and strength, simplifying the task of material selection for various applications.

The BigRep PLA carabiner lifted the 733.9 lbs machine, then the team added more weight to the printer to make it 1117.74367 lbs (507 kg) and it held, comfortably. – MotionLab

SOLUTIONS IN ACTION

How NeoMetrix Utilized 3D Scanning to Revolutionize Complex Part Manufacturing

Transforming Complex Volute Manufacturing with 3D Scanning

3D Scanning for Mining Applications

Download this free EBook to discover how 3D scanning is helping mining companies locate and access critical resources, maintain shafts and machinery, manage assets and improve safety.

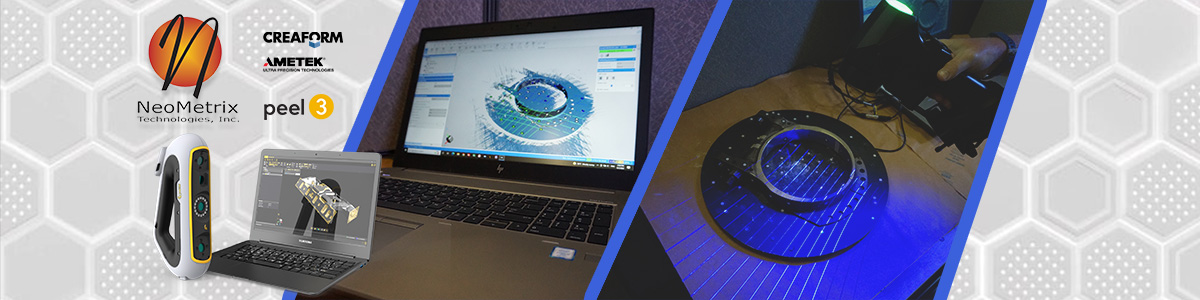

DISTRIBUTORS AND PARTNERS OF: