A New Era of 3D Scanning, Reverse Engineering & Additive Manufacturing

Engineering and manufacturing are evolving faster than ever—and so are the expectations placed on teams who design, prototype, validate, and produce real parts. Yet even as technologies advance, most companies still face a major bottleneck: very few partners can support the entire digital engineering process from start to finish.

Some specialize in 3D scanning.

Others focus on reverse engineering or CAD modeling.

A handful sell industrial 3D printers.

But almost no one does all three with industrial-level accuracy and experience.

That’s exactly what sets NeoMetrix Technologies apart.

Most Companies Offer a Single Piece

NeoMetrix Delivers the Full Solution.

Today’s engineering challenges don’t fit neatly into single-service categories. When a company only offers scanning or only sells equipment, customers are forced to navigate disconnected vendors, mismatched data, and technology that doesn’t fully integrate into their real production environments. NeoMetrix eliminates those friction points entirely.

We provide:

-

High-accuracy 3D scanning & metrology powered by Creaform’s latest platforms

-

Reverse engineering & CAD modeling with Geomagic Design X

-

Industrial-grade additive manufacturing from Markforged, INTAMSYS, and BigRep

-

Equipment sales, consulting, and full integration support

-

Engineering services for any stage of your product’s development

The result?

A single partner who can capture your data, convert it to usable CAD, manufacture your parts, or equip you with the tools to do it in-house.

That level of capability is rare, and it’s exactly why NeoMetrix is becoming the go-to resource for engineering teams heading into 2026.

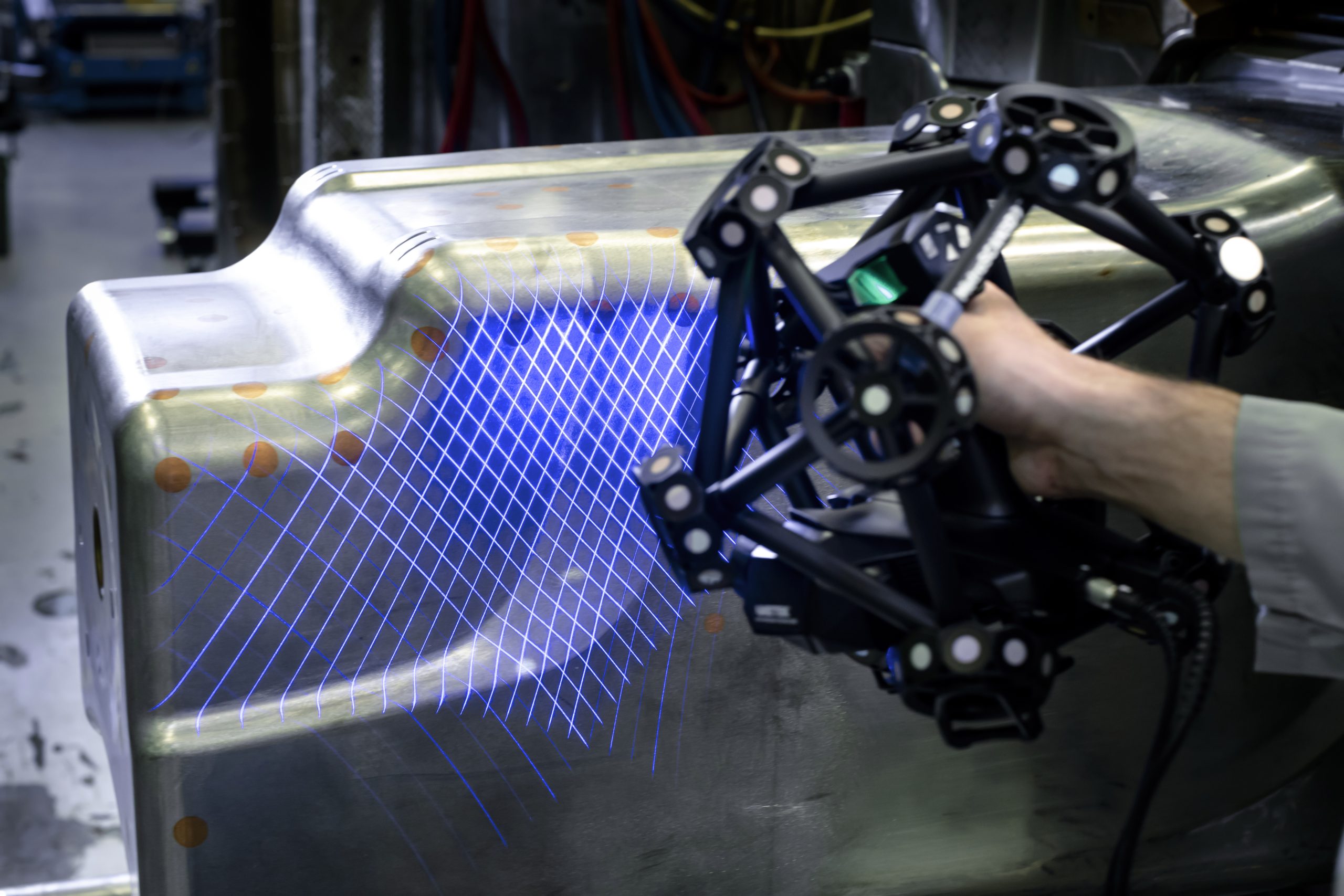

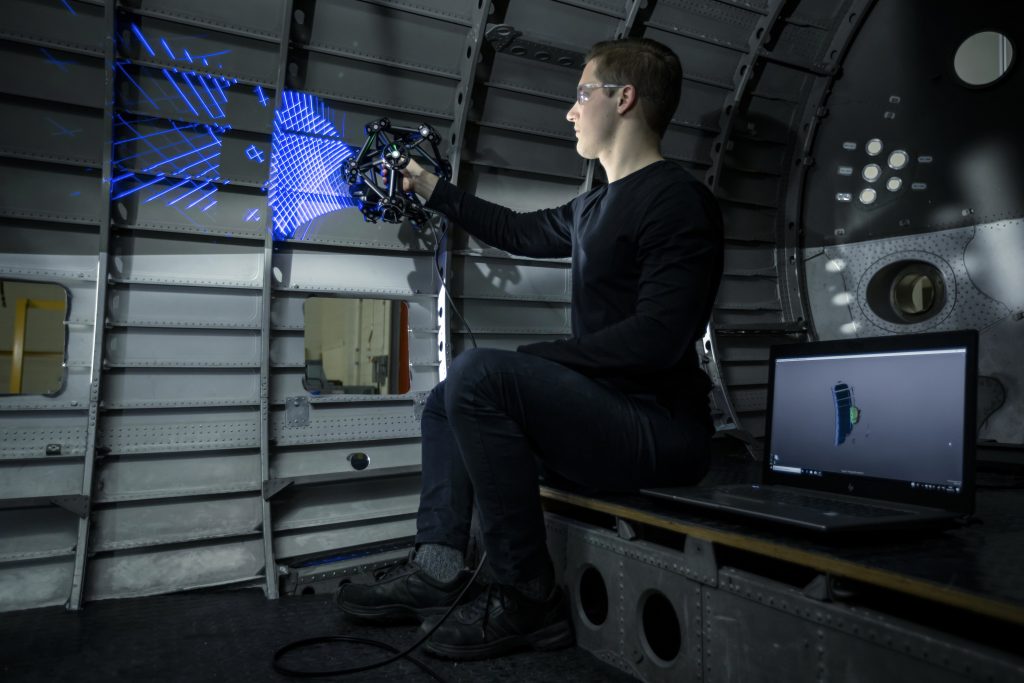

High-Accuracy 3D Scanning: Where Precision Starts

Modern engineering begins with the truth—accurate measurements. Our metrology tools, including the HandySCAN BLACK+, MetraSCAN BLACK Elite, and the newest Creaform OS, capture clean, detailed geometry even in real manufacturing environments.

This gives engineers confidence in the data they rely on, whether it’s for reverse engineering, inspection, or validation.

Creaform’s newest additions!

The latest HandySCAN EVO and HandySCAN PRO models introduce upgraded optics, higher mesh resolution, and smarter calibration features, setting a new benchmark for portable metrology solutions. Now available at NeoMetrix!

HandySCAN EVO – Learn More

HandySCAN PRO – Learn More

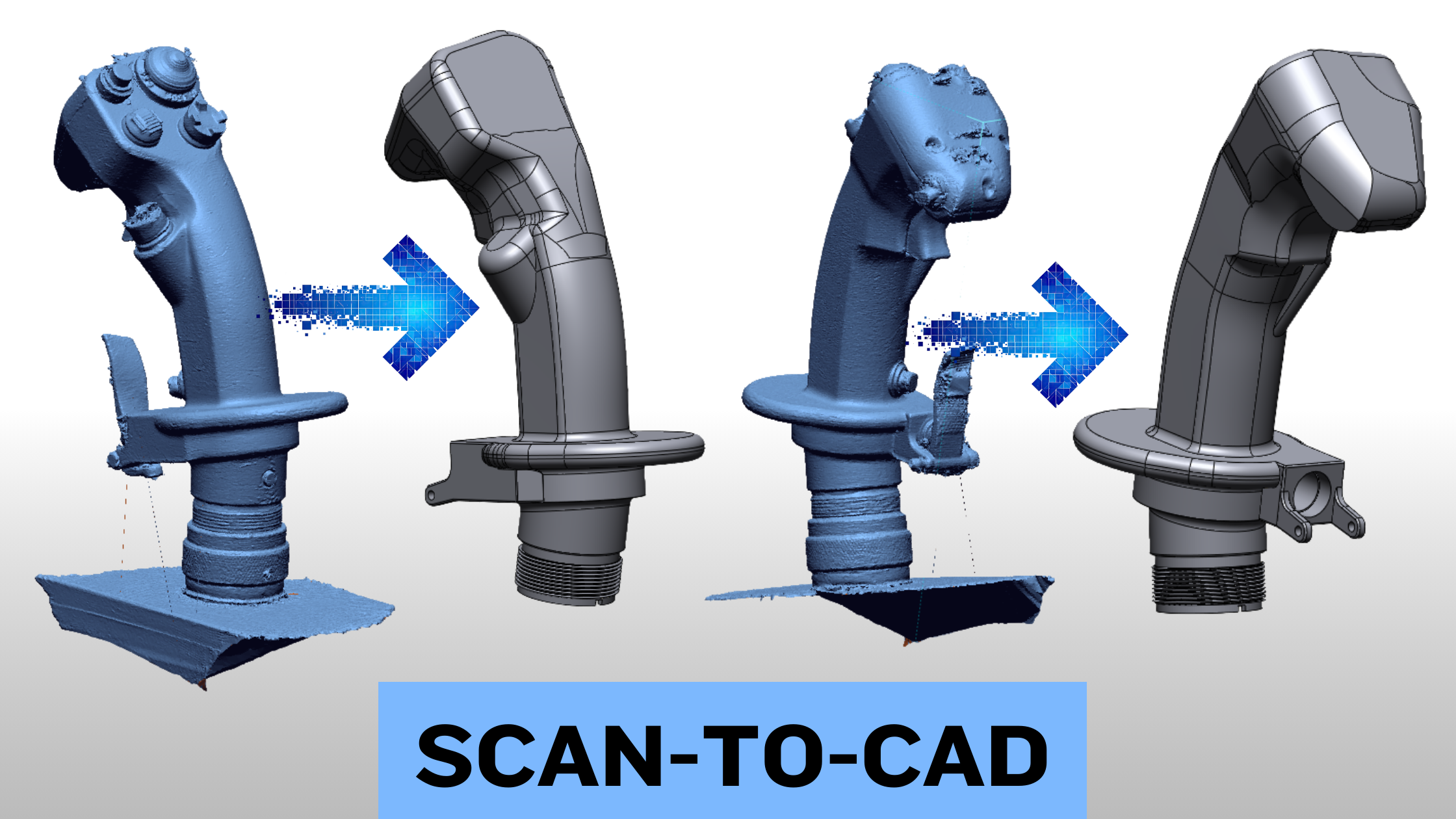

Reverse Engineering & Modeling: Turning Reality Into Intelligent CAD

Scans alone aren’t enough. Engineers need editable models that behave properly in SolidWorks, Creo, NX, Fusion 360, and other CAD platforms.

Using Geomagic Design X, NeoMetrix transforms raw scan data into fully featured, native CAD with precise surfaces, sketches, and parametric intelligence.

This is essential for:

-

Legacy part recreation

-

Product upgrades

-

Tooling and fixture design

-

Competitive benchmarking

-

Design optimization

Few companies can scan accurately—fewer can also model at this level.

Industrial Additive Manufacturing: From Prototype to Production

Additive manufacturing is no longer just for prototypes. With systems like:

-

INTAMSYS FUNMAT PRO 310 APOLLO (high-temp PAEK, PEEK, PEKK)

-

Markforged composite and metal systems

-

BigRep’s large-format industrial printers

NeoMetrix helps teams produce stronger parts, faster iterations, and production-ready components.

Whether developing tooling, jigs and fixtures, housings, industrial enclosures, or end-use parts, we deliver functional performance—not just printed shapes. Contact us to learn more about available materials your parts can be produced in!

Going Into 2026

Engineers Need More Than a Vendor — They Need a Partner

Engineering cycles are shrinking. Materials are getting more advanced. Tolerances are tightening.

Manufacturers need reliable data, intelligent modeling, and strong, accurate parts made from real industrial materials.

NeoMetrix is built for those challenges.

It’s no longer enough for a company to only scan, or only model, or only print.

The next generation of engineering demands integration, accuracy, and execution across all three.

That’s why NeoMetrix is more than a service provider—we’re a true engineering partner capable of supporting virtually any project you bring to the table.

Ready to Elevate Your Engineering Capabilities?

Whether you’re developing prototypes, recreating legacy components, validating geometry, or producing high-performance parts, NeoMetrix has the tools, technology, and expertise to help you move faster with confidence.

👉 Schedule a demo

👉 Speak with our engineering team

2026 is coming fast. Let’s build the future together.