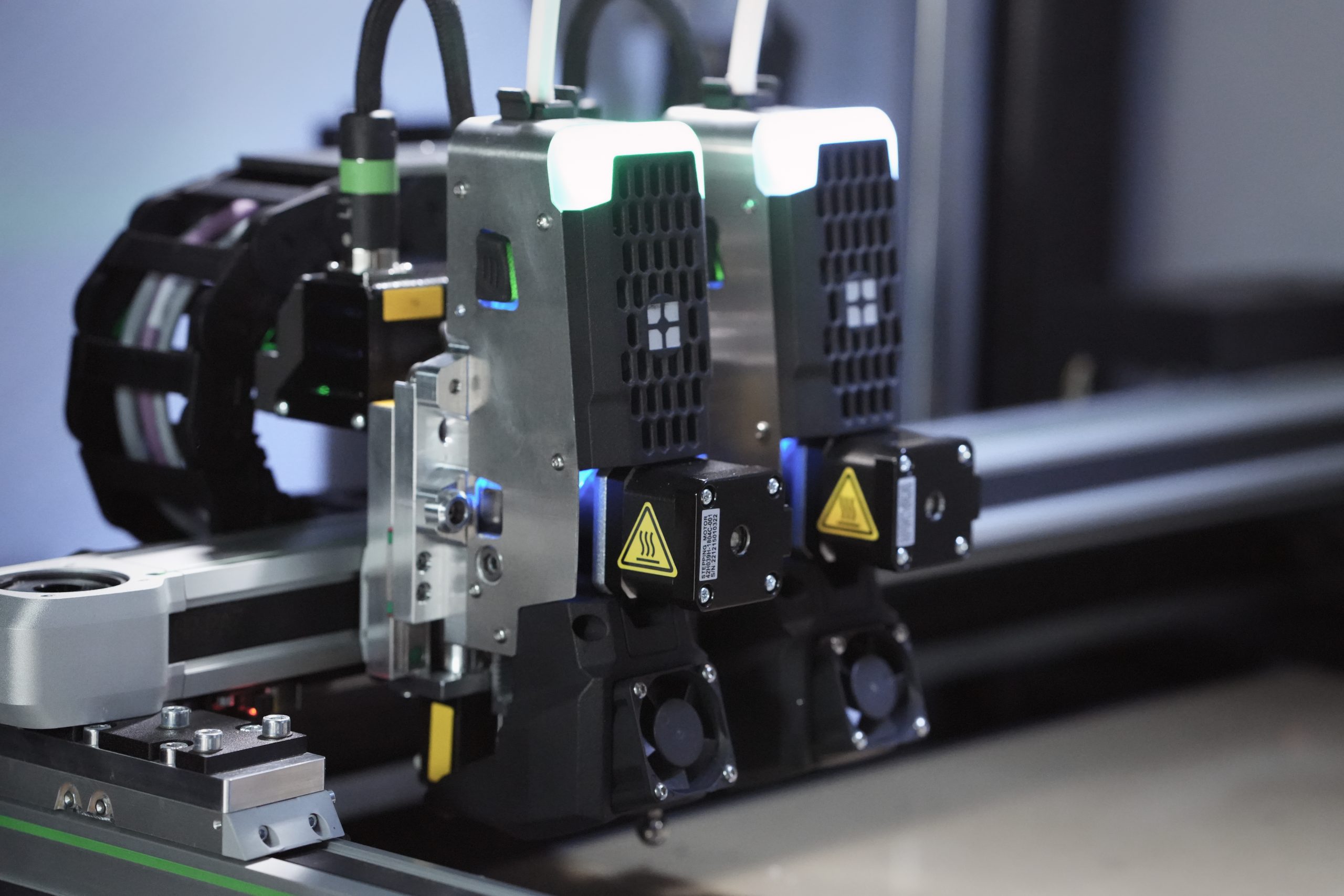

When it comes to large-format additive manufacturing, precision and speed are often seen as a trade-off. At NeoMetrix Technologies, we’re showing engineers and manufacturers that with the BigRep VIIO250, you can have both.

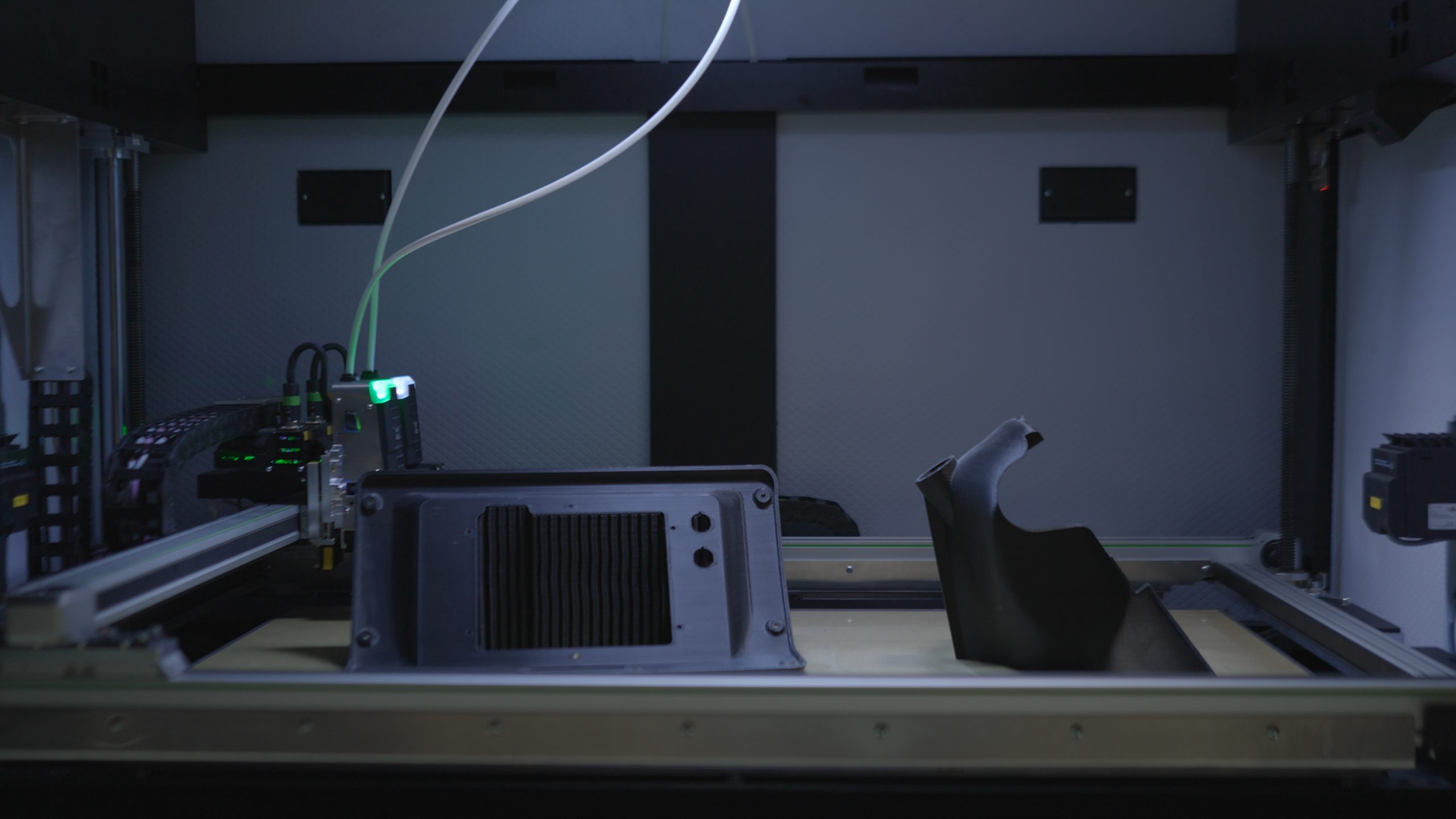

To demonstrate this, we printed a visual display matrix part showcasing eight individual samples, each with varying layer heights and nozzle sizes. The purpose? To give engineers a clear, tangible view of how layer resolution affects both surface finish and print time—empowering better decision-making for product development and manufacturing workflows.

Layer Height Matrix: .6 mm vs. .4 mm Nozzle Sizes

We used two nozzle sizes—0.6 mm and 0.4 mm—and printed four parts with each, altering the layer height settings to highlight the finish and speed differences.

-

0.4 mm Nozzle:

Enabled us to run prints with layer heights from 0.1 mm up to 0.4 mm, achieving remarkably fine surface detail at the lower end. Ideal for parts requiring tight tolerances or visual aesthetics. -

0.6 mm Nozzle:

Delivered layer heights from 0.3 mm to 0.6 mm, with significantly faster print times. This is ideal for structural prototypes or end-use parts where throughput is key and ultra-fine surface resolution isn’t critical.

Print times can be decreased up to 50% by using an even larger 1mm nozzle.

Why This Matters

With the BigRep VIIO’s advanced slicing capabilities, users gain full control over layer height, nozzle size, and print parameters. This flexibility allows you to tailor the printing process to the application—whether you need visual prototypes with high detail or functional parts built quickly and cost-effectively.

This kind of control isn’t just a feature—it’s a productivity multiplier. You’re no longer locked into compromises. Instead, you can fine-tune each print job to balance speed, strength, and surface quality, all within one powerful platform.

Ready to Take Control of Your Print Workflow?

Design Flexibility

Scalability

Print Engineering-grade Materials

Cost Efficiency

Contact NeoMetrix Technologies today to learn more about the BigRep VIIO, schedule a live demo, or request a sample print. Our team of engineers is ready to help you explore how additive manufacturing can streamline your production.