Introducing the HandySCAN Black+ Elite: Enhancing Engineering-Grade 3D Scanning

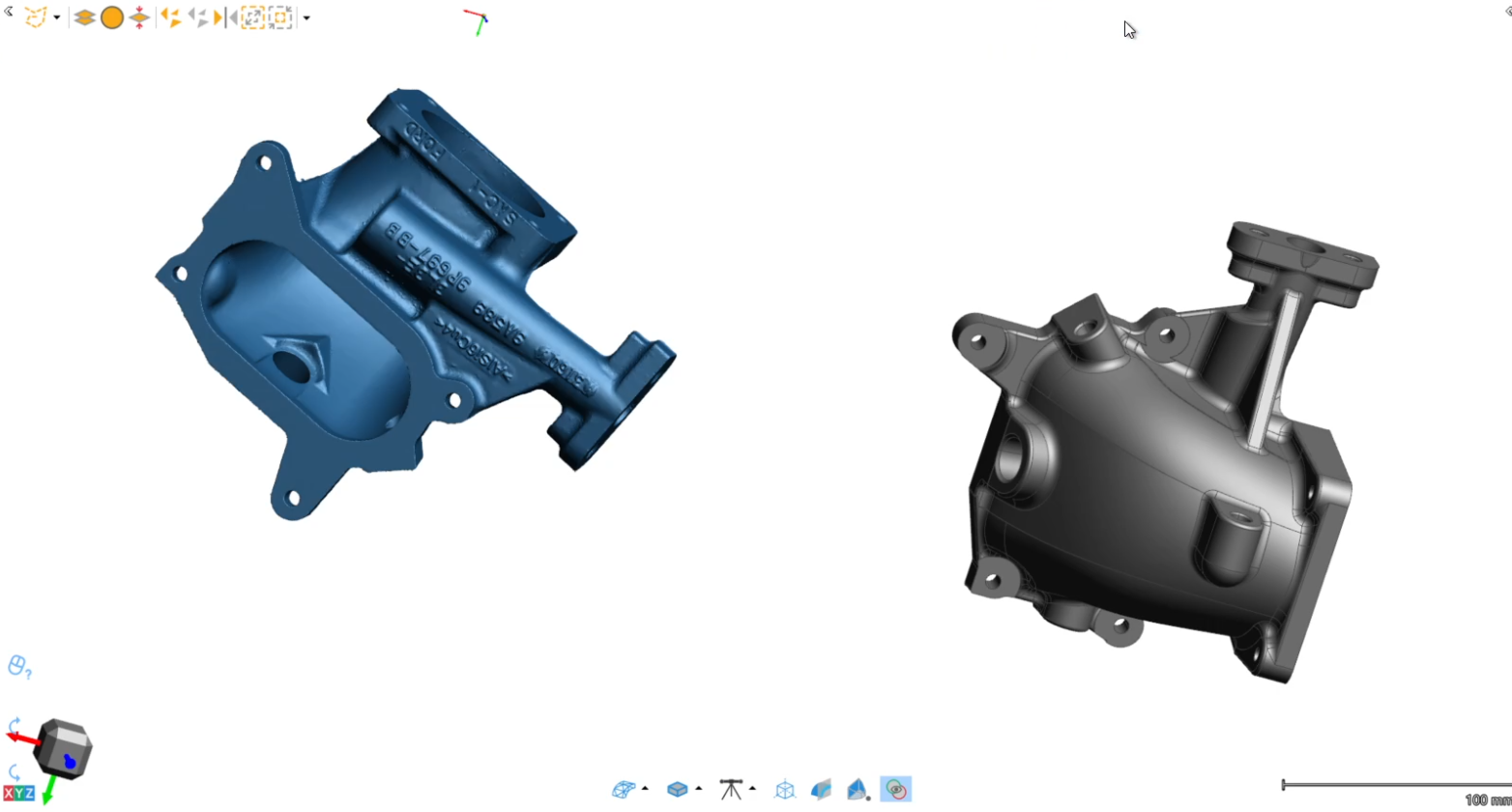

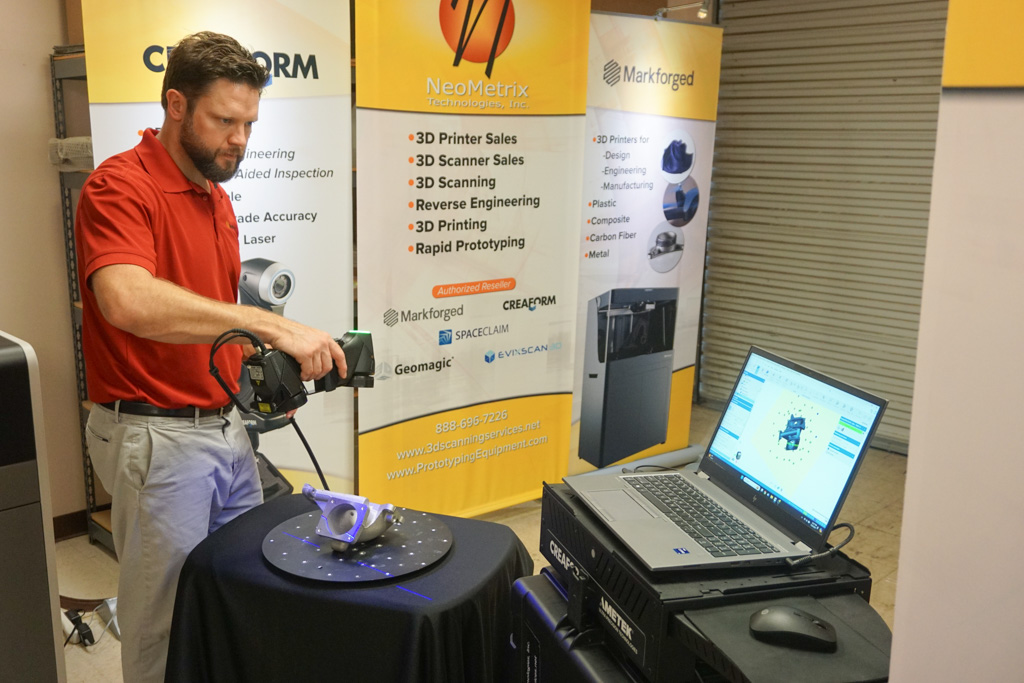

At NeoMetrix, we’re constantly exploring the latest technology to ensure our clients have the tools they need to achieve their goals. Recently, we put the next-gen HandySCAN Black+ Elite to work for a computer-aided inspection of a sample part, demonstrating how this powerful scanner captures exact dimensions and surface data in high resolution, ultimately providing a comprehensive inspection report.

The Power of Computer-Aided Inspection and Custom Reports

The HandySCAN Black+ Elite stands out for its ability to capture high-accuracy 3D data in even the most complex environments. For our inspection process, the scanner was able to deliver exact measurements and intricate surface details of a sample part, creating a digital replica with remarkable precision. This level of detail is essential in applications where every micron counts—whether in aerospace, automotive, or mechanical engineering.

Turning Data into Actionable Insights

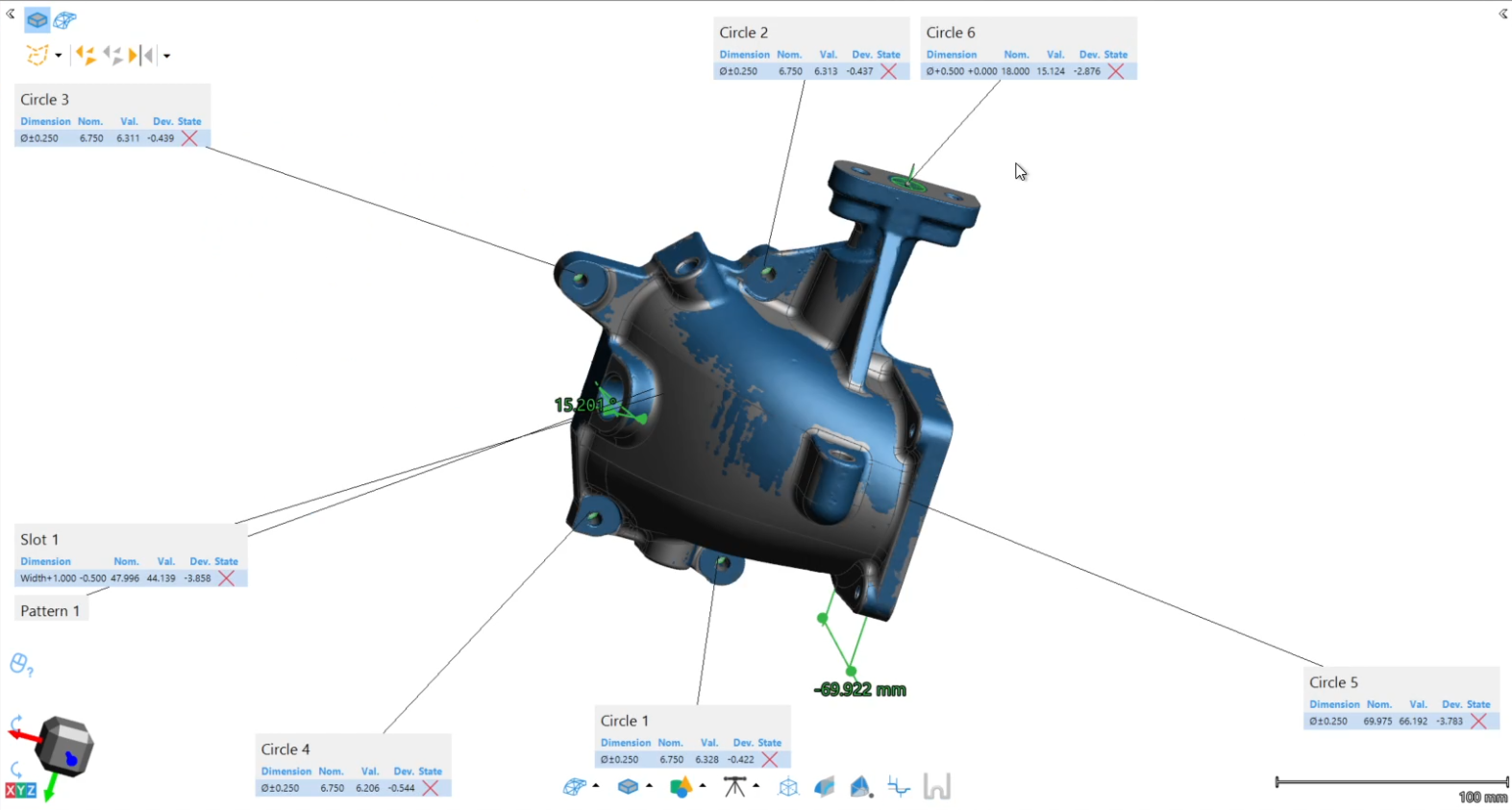

What sets this process apart isn’t just the scanning—it’s the data analysis and reporting. After capturing the scan, we used computer-aided inspection software to generate a comprehensive final report. This report is more than just a collection of numbers; it’s a visual and data-rich resource that guides engineers and decision-makers throughout the product development cycle.

The report can include dimensional comparisons against CAD models, color maps for visual deviation analysis, and critical measurements that highlight where adjustments might be needed. Whether it’s identifying manufacturing flaws or validating the integrity of a design, the information provided allows businesses to make informed decisions quickly and confidently.

REVERSE ENGINEERING & COMPUTER-AIDED INSPECTION WORKFLOWS

Aligning Your Scan to the Original CAD Model

Ensure precise results by aligning your scan data with the original CAD model. This step is crucial for comparing the scanned object to its designed specifications, allowing for accurate assessments and modifications.

Performing an Accuracy Analysis/Inspection

Conduct a thorough accuracy analysis to identify deviations and ensure quality control. The HandySCAN Black+ Elite enables detailed inspections, highlighting discrepancies between the scanned object and the CAD model with high precision.

Generating a Comprehensive Report

After the analysis, generate a comprehensive report that documents measurements, dimensions, accuracies, and inaccuracies. This report provides a clear overview of the scanning results, supporting informed decision-making and process improvements.

Applications Across Multiple Industries

Industries like automotive, aerospace, marine, and industrial manufacturing are increasingly relying on advanced 3D scanning and inspection to fine-tune their products. With the HandySCAN Black+ Elite, these industries can seamlessly integrate high-precision inspection into their workflow. From prototype validation to final product inspections, the data generated helps teams optimize every step of the process.

Key Benefits Highlighted

- High-Resolution Scanning: Capture fine details with metrology-grade accuracy.

- Efficient Workflow: Streamline your processes with fast scan-to-mesh capabilities.

- Versatile Applications: From automotive, aerospace, to mechanical engineering, unlock the potential for innovative product development and manufacturing solutions.

The Bottom Line: Accurate Data Drives Better Business Decisions

In today’s competitive landscape, having detailed and accurate data is crucial to making the right business decisions. With the HandySCAN Black+ Elite, NeoMetrix delivers not only high-precision scans but also detailed reports that offer actionable insights. By combining cutting-edge scanning technology with advanced reporting, we empower engineers and product teams to deliver superior results.

If your business is looking to enhance its product development process with precise inspection and comprehensive data, reach out to us at NeoMetrix. We’re here to help you leverage the power of next-gen 3D scanning technology for your business.

NeoMetrix Technologies has been a trusted provider of precision measurement solutions for inspection and reverse engineering for 20+ years. Specializing in 3D Scanning, Reverse Engineering, Inspection and 3D Printing, our team has tackled it all—complex components, large-scale projects, and everything in between. From local services to on-site support, we’re equipped to handle any challenge, delivering precision and innovation every step of the way. Serving Major Industries: Aerospace & Defense, Automotive, Marine, Education, Mining, + more.

For more information, contact us at www.neometrixtech.com or 888-696-7226