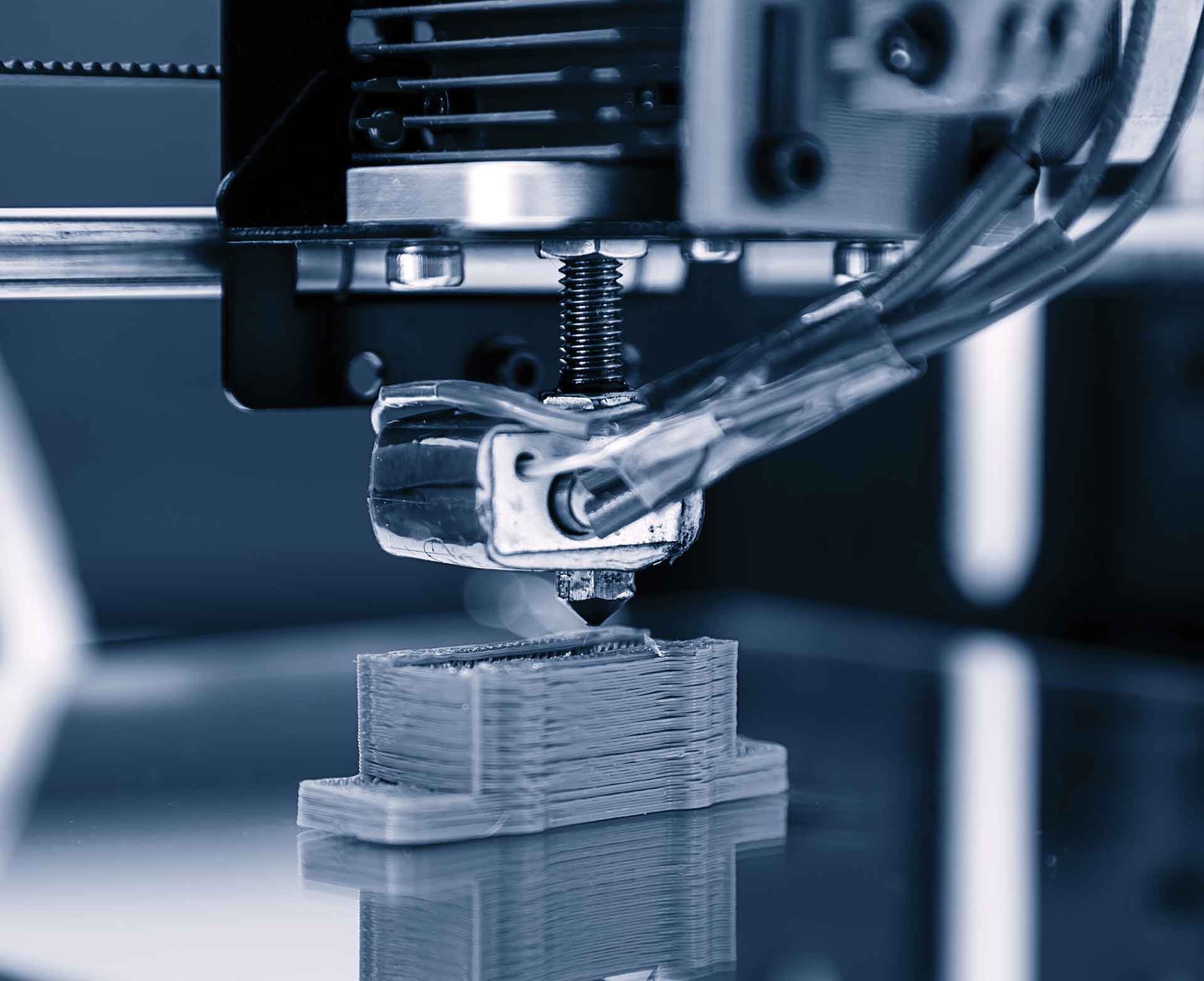

The benefits of having two (or more) extruders are perhaps not as obvious as you may think in the world of additive manufacturing.

The easiest trap to fall into is thinking your printer will print faster because of multiple extruders. They will in fact speed up the overall printing process, but not because they print faster – because they print continuously.

Having multiple extruders allows you to have multiple filaments ‘piped in’ and ready to be used whenever the object being printed requires them, and this is where the saved time comes from.

Having different filaments ‘ready to go’ means you no longer have to pause a print, empty out the extruder of the previous filament, feed in the next filament, and resume the print every time you need a different material. The printer will simply call on which filament it needs, when it needs it.

Unique Parts

The true beauty of a dual extruder 3D printer is the ability to combine model (M) and support (S) materials. Essentially, you are able to 3D print your model in a PLA thermoplastic material and simultaneously print water soluble support structures out of BVOH. This is the science that enables true design freedom and flexibility. You can design and print in a 3-dimensional space that goes way beyond surface level. Now, it’s possible to create interlocking features for workable gears or internal channels for fluid and air passageways. This is only possible with the use of support structures that are literally washed away once the 3D print is finished.

Ergonomic Improvements

Ergonomics is the study of human and product (or machine) interaction. Those who design consumer products are constantly iterating prototypes to test ergonomics and user satisfaction (i.e. how to make user friendly, comfortable products). You’ll notice that the majority of consumer products and electronics are designed and built with soft touch overmolds, rubber or TPU materials to enhance comfort. Think of a grip on a power tool. With dual extruder 3D printers, engineers can combine rigid plastics with soft touch flexible materials to produce overmolds. Material 1 is a Pro-HT plastic with enhanced strength properties combined with Material 2, a TPU categorized as a Shore 98 A flexible material.

Improve Aesthetics

We have discussed functionality, now let’s turn to the possibilities for artistic features with multicolored 3D printing. We do not live in a monochromatic world, so we do not expect you to design for one. Oftentimes, prototypers will present their products to focus groups or potential customers for invaluable feedback to validate a design. It’s important to provide parts that are aesthetically pleasing and match a color scheme for the end product. Having multi colored parts is valuable for other applications – such as color coded safety fixtures on assembly lines, diagram models used in healthcare communications or other research, education or artistic purposes.True Mass Production

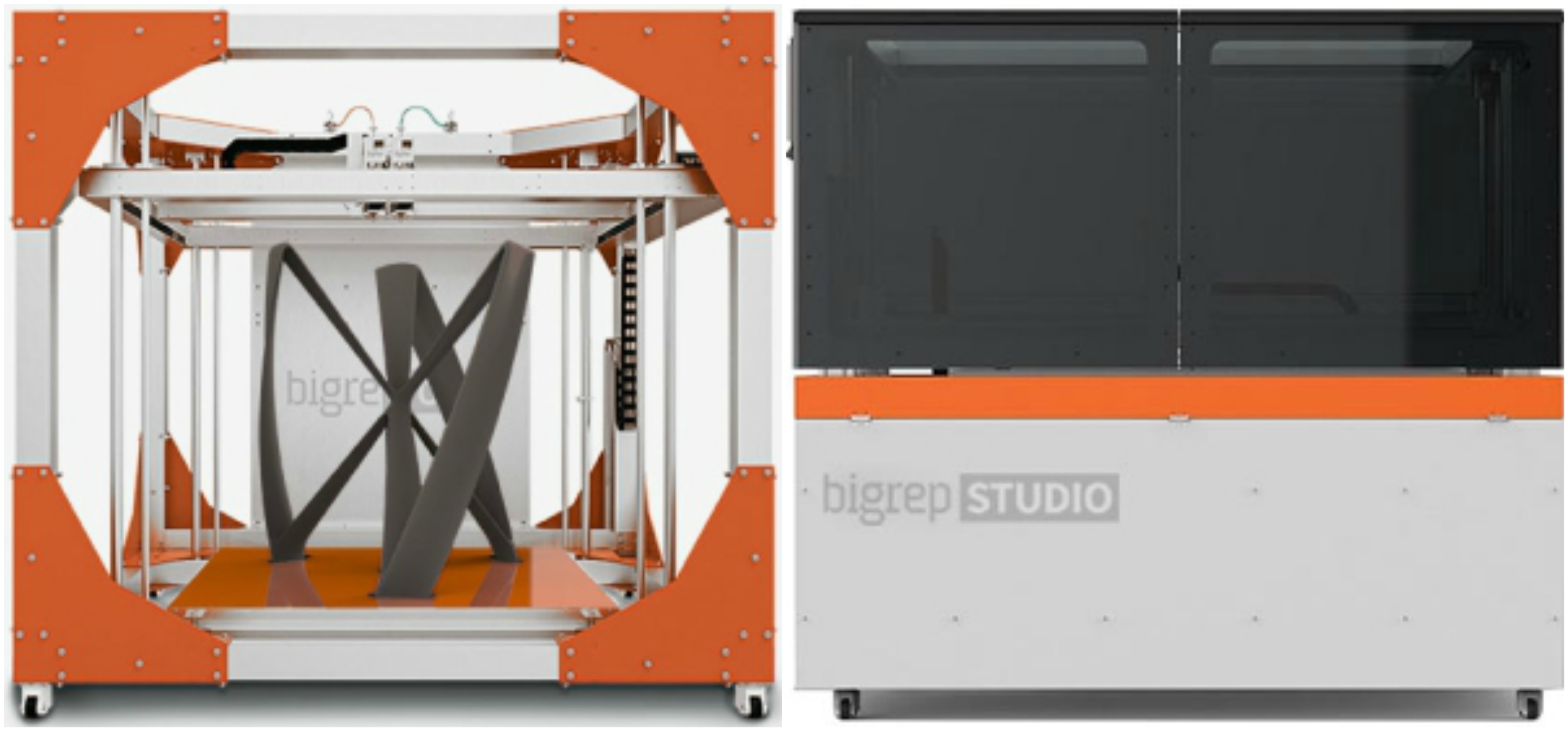

Unique to BigRep is that ability to print Tandem mode, which splits the printing platform in half and enables the production of parts in twice the time. The dual extruders are separated by distance, but connected by advanced software so that they mimic each other and print identical parts on the platform. This is ideal if you wish to begin batch production and want to bypass tooling, machining and other costly manufacturing methods. BigRep already offers one of the largest build platforms in the industrial market, and Tandem mode enables manufacturers to react immediately and produce parts on demand. This is unheard of in the marketplace today, and provides a significant time and cost savings advantage to users.Professional 3D Printing Service Available at NeoMetrix

The Future of Dual Extruder 3D Printers

To summarize the benefits: Industrial 3D printers and dual extruder technology with BigRep enables you to produce impossible parts with support material. It exceeds a variety of functional requirements such as mechanical property improvements or soft touch overmold applications. Dual extruders provide a pathway for artists, architects and creatives to think outside of conventional fabrication methods and bring color, realism and life to their designs. Where does dual extruder technology go from here? Are three heads better than two? Maybe, but the evidence isn’t there to support it quite yet. In the meantime dual material printing continues to be such a major advantage for industrial engineers and designers. We recommend staying in touch with us, since we are constantly evolving our technology and materials to further the adoption of 3D printing.

Prints using PLA, PETG, Pro HT, TPU, PA6/66