Expanding Businesses with Carbon Fiber 3D Printing

The carbon fiber 3D printing service market is poised for significant growth, driven by advancements in additive manufacturing technologies and increasing demand across various industries such as aerospace, automotive, and healthcare.

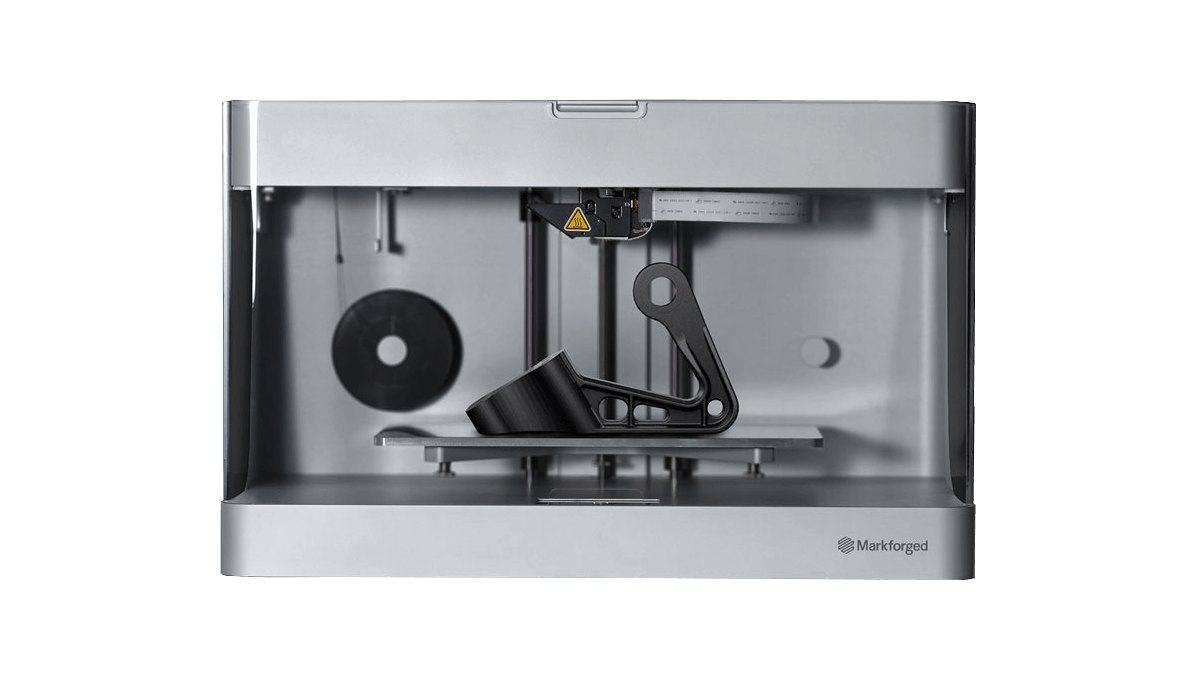

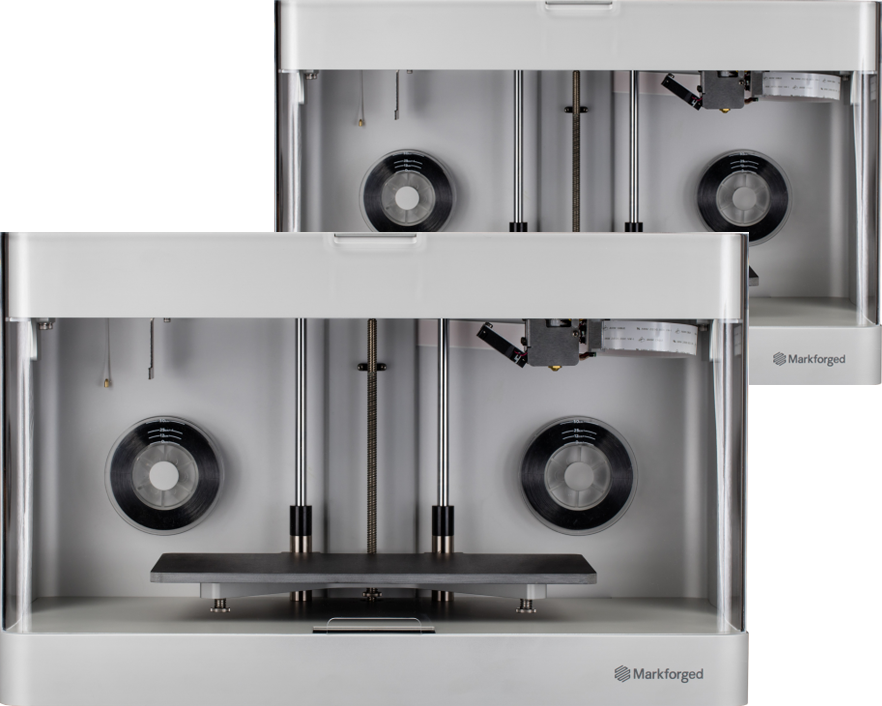

While carbon fiber 3D printing has been around for nearly a decade, it has recently surged to prominence, transforming the landscape of additive manufacturing. Today, many 3D printer manufacturers are racing to leverage the term “carbon fiber 3D printing,” but it’s essential to note that not all carbon fiber is created equal. At NeoMetrix Technologies, we focus on delivering the highest standards in 3D printing with the Markforged Mark Two and X7, renowned for their exceptional carbon fiber and reinforced printing capabilities.

Advancing with Carbon Fiber 3D Printing: Trends and Challenges

Technological Advancements

Innovations in 3D printing, especially in carbon fiber composites, are boosting the efficiency and quality of printed parts. New carbon fiber filaments and Continuous Fiber Reinforcement (CFR) technology are enhancing mechanical properties like tensile strength, stiffness, and thermal resistance. These improvements are making carbon fiber 3D printing more precise, reliable, and versatile, ideal for demanding applications in aerospace, automotive, and more. As these technologies evolve, they expand the capabilities and reliability of carbon fiber 3D printed components.

Industry Adoption and Market Dynamics

Industries, particularly aerospace and automotive, are increasingly using carbon fiber 3D printing for rapid prototyping, customization, and lightweight, high-strength parts. This trend is driven by the need for faster prototyping, custom designs, and cost savings through additive manufacturing. The market is seeing more competition, pushing companies to enhance their services, innovate pricing, and expand globally. Challenges include high initial costs, quality assurance issues, and limited access to high-quality carbon fiber materials, but these hurdles continue to drive innovation in the industry.

Learn how we can put our technology to work for you.

“I asked NeoMetrix to produce a part that required accuracy and it was delivered with a short turnaround time. They knocked it out of the park. Love working with these guys.”

— Will B.,- Solidprint 3D

Why Markforged Stands Out

Continuous Fiber Reinforcement (CFR):

Unlike traditional short fiber composites, CFR involves laying long carbon fiber tows in various orientations within the print, significantly enhancing the part’s mechanical properties. This method provides:

-

-

- Superior Strength & Stiffness: Parts reinforced with continuous carbon fiber can rival aluminum’s strength while maintaining lightweight characteristics.

- Enhanced Durability: CFR parts exhibit superior impact resistance, heat resistance, and long-term durability, making them ideal for high-stress applications.

-

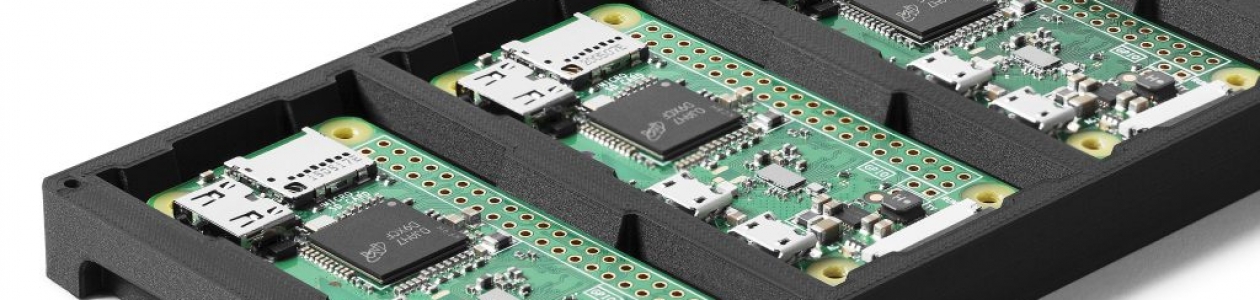

Onyx and Onyx-CF Materials:

- Onyx: A proprietary composite of nylon and chopped carbon fiber, Onyx delivers exceptional surface finish and dimensional accuracy.

- Onyx-CF: Combining Onyx with continuous carbon fibers, Onyx-CF parts are incredibly strong and durable, ideal for producing high-performance parts that require rigorous testing and durability.

Benefits of Carbon Fiber 3D Printing with Markforged:

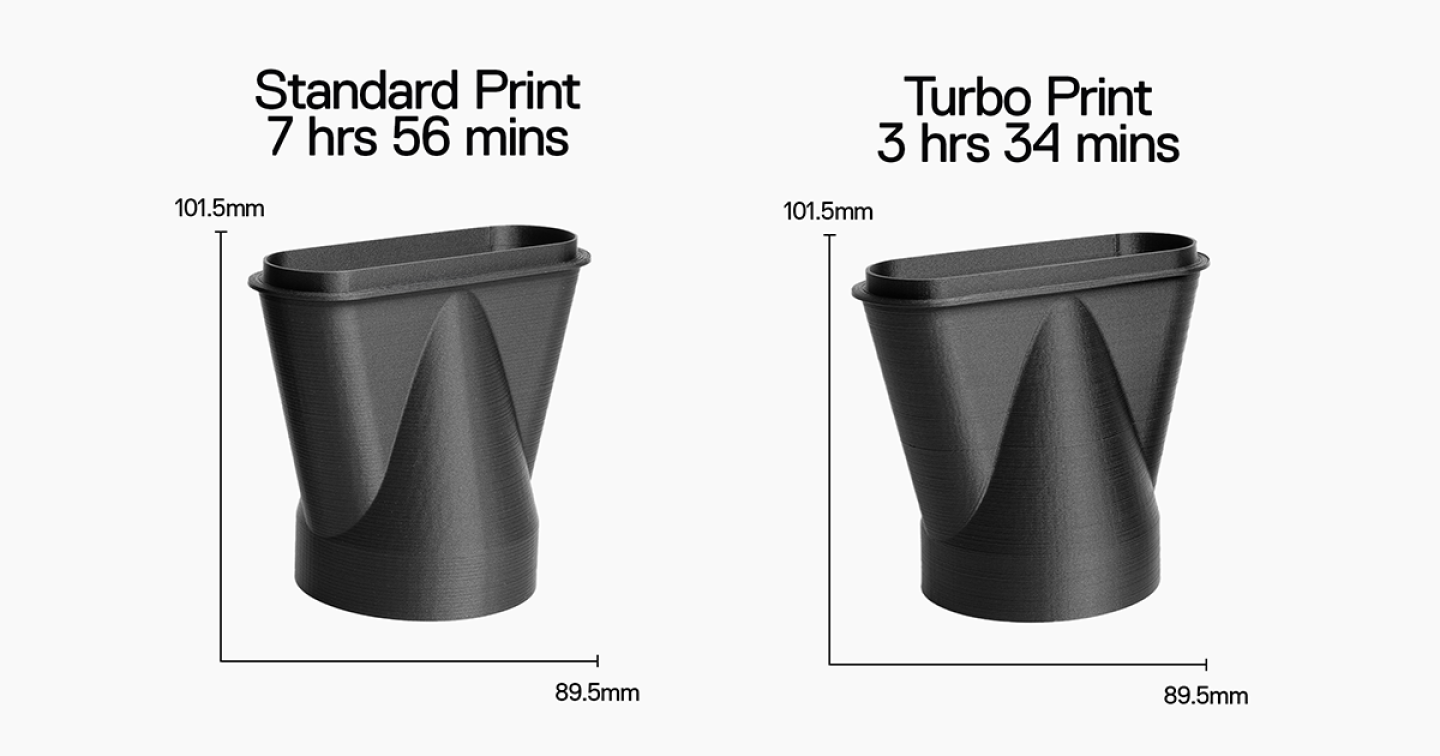

Carbon fiber 3D printing with Markforged offers several key benefits. The Turbo Print feature allows for accelerated production by doubling print speeds, which significantly reduces time-to-market without compromising quality. This technology is also cost-effective, reducing material waste and overall production costs while enhancing the quality and performance of the printed parts.

Let’s see how we can put our technology to work for you.

Fill out this form and our team will get in touch with you!