The adaptive manufacturing platform that connects part design, production, and inspection with a powerful AI.

The adaptive manufacturing platform that connects part design, production, and inspection with a powerful AI.

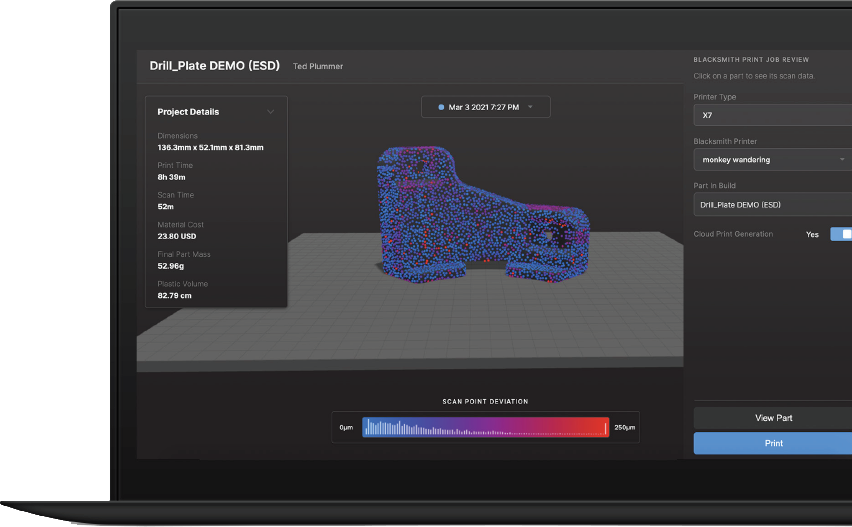

Blacksmith is a subscription feature available through Eiger, the additive manufacturing software for Markforged. It scans, measures, and compares dimensional accuracy data of printed parts to their design files — giving manufactures reliable parts right off the print bed.

How it works:

1. Calibrate Machine – The onboard laser Micrometer scans an OEM certified artifact to field calibrate the X7, enabling unparalleled printer consistency and scan accuracy

2. Print & Scan Part – As you slice a part, Eiger’s patented intelligent scanning algorithm creates an integrated scan toolpath. The X7 scans the part while printing and creates a point cloud of dimensional data.

3. Analyze Data – Blacksmith collects measurement data during the print, and assembles a point cloud for review in Eiger. This point cloud is automatically registered and overlaid on the input STL for comparison.

4. Generate Report – Eiger presents this error field in an online report. Using these tools, you can set tolerance limits, compare different prints of the same part, and browse a library of print quality data.