From customized car body shops to commercial vehicle manufacturers, aftermarket manufacturing is a multi-billion-dollar industry built on innovation, customization, and precision. Yet, the challenges of producing low-volume, highly complex parts have long limited efficiency — until now.

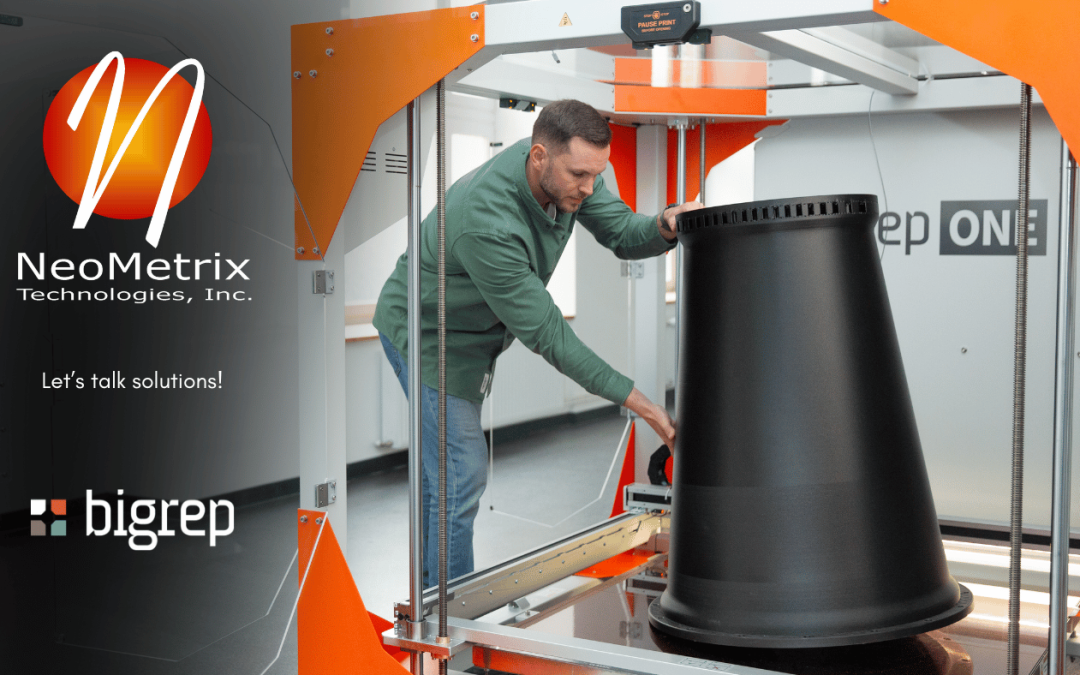

With large-format 3D printing from BigRep, businesses can produce full-scale parts in one go, eliminating the need for segmented prints or time-consuming attachments. This breakthrough not only streamlines production but also delivers superior strength, accuracy, and design freedom.

One-Go Printing for Faster, Stronger, Smarter Results

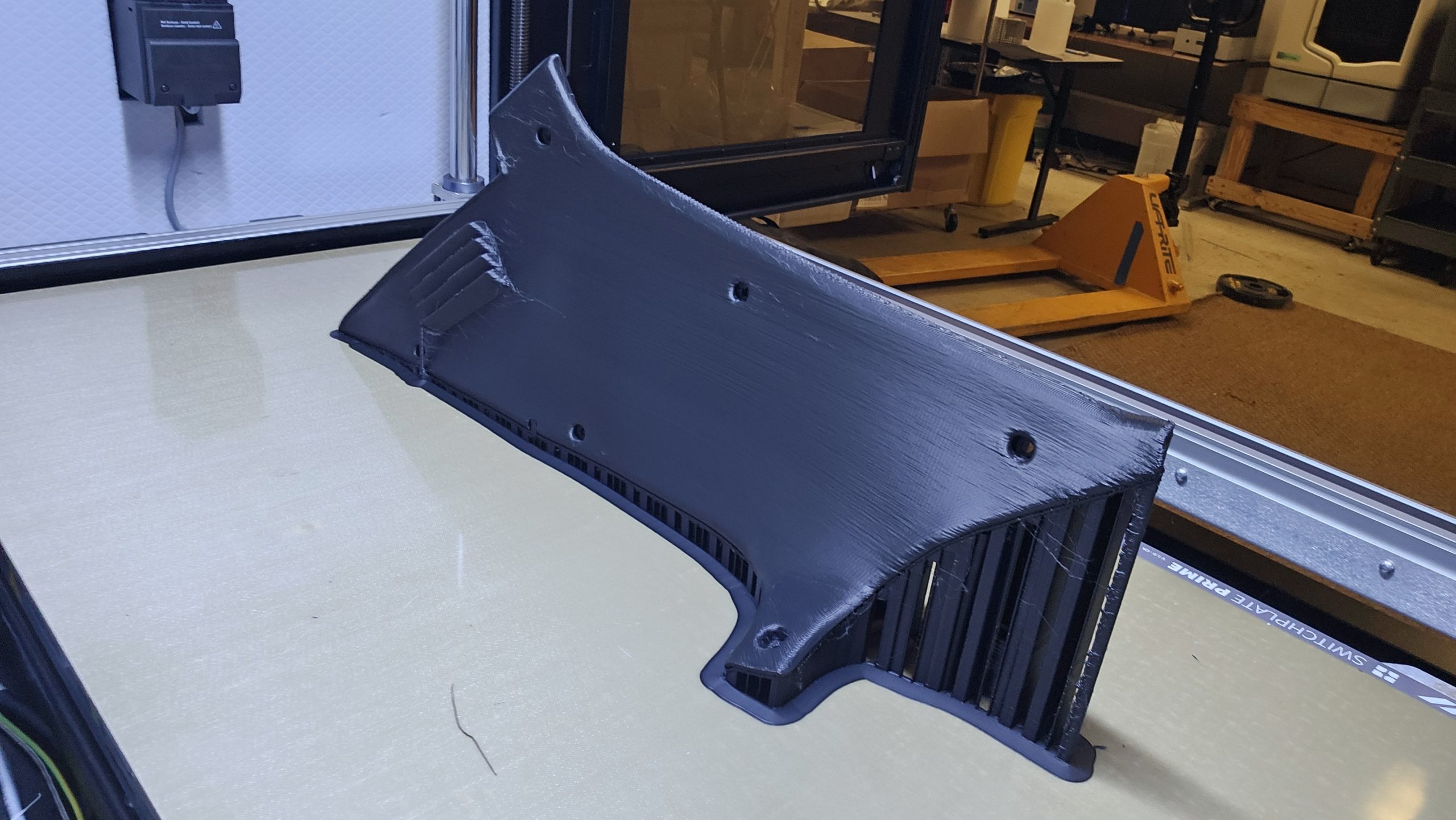

Traditional manufacturing and small-format 3D printers often require that large parts be split into sections and assembled later — a process that introduces weak points, misalignments, and extra labor.

BigRep’s industrial-scale build volumes, such as the BigRep ONE and BigRep VIIO, enable technicians to print entire components at once — from custom bumpers and dashboards to jigs, fixtures, and molds.

The benefits include:

-

Improved durability: No assembly seams or weak joints.

-

Reduced labor time: Fewer post-processing steps and faster turnaround.

-

Design flexibility: Easily modify and iterate custom parts for unique vehicle builds.

-

Cost efficiency: Save on tooling and reduce material waste.

Driving Customization & Restoration in the Aftermarket

Whether it’s a custom body panel for performance tuning, bespoke interior trim, or prototype tooling for vehicle accessories, 3D printing empowers automotive and motorosport engineers and fabricators to meet client demands without the limitations of traditional processes.

BigRep’s compatibility with a wide range of engineering-grade materials — including carbon fiber-reinforced filaments — ensures that every printed component meets the performance requirements of real-world automotive applications.

Scale Innovation with BigRep

As the automotive aftermarket continues to evolve, BigRep’s large-format 3D printers are giving manufacturers the competitive edge to innovate faster and deliver higher-quality results — all while reducing costs and lead times.

Aftermarket + Restoration Project

Aerospace: Lightweight Structures and Rapid Prototyping

The aerospace & defense sector demands precision, reliability, and material efficiency — areas where BigRep 3D printing technology excels. Engineers can create large-scale functional prototypes, jigs, and lightweight tooling in a single print, minimizing assembly complexity and ensuring dimensional accuracy.

Typical aerospace applications:

-

Large aerodynamic fairings and composite layup tools

-

Custom fixtures and assembly jigs

-

Rapid prototyping for interior components and housings

BigRep’s high-strength, heat-resistant filaments make it ideal for creating functional prototypes and tooling that endure real-world testing environments — all while reducing lead times and overall production costs.

Produce a wide range of aircraft tooling and components!

Large-Format 3D Printing for Marine Applications

In the marine industry, durability and precision are essential. BigRep’s large-format 3D printers enable engineers to produce full-scale hull components, molds, and fixtures in one continuous build — reducing material waste and production time.

Applications include:

-

Custom propeller prototypes and hydrodynamic testing models

-

Full-scale molds for fiberglass layups and composite parts

-

Lightweight brackets and enclosures for marine interiors

By printing in one go, marine fabricators eliminate joints and attachment points that can become failure zones under stress or vibration, ensuring stronger, more reliable components.

Unlock Industrial-Scale Possibilities

Whether for automotive, marine, or aerospace, BigRep’s industrial 3D printing systems are redefining what’s possible in modern manufacturing. The ability to print full-scale parts in a single process delivers unmatched design freedom, speed, and efficiency — empowering innovators across every sector to go from concept to production faster than ever.