A Bit of Context at the Starting Line:

Mark Bovey holds the keys to a 1971 GMC 1500 long bed pickup truck. But not any GMC 1500: This C-Series farm truck, originally built to haul cargo, was given to Bovey by his dad. They started to restore it when Mark was only 14. He has basically always been a car and truck enthusiast. Since then, the vehicle is being perpetually improved or altered.

Today, the vehicle is dubbed the Targa Truck, since it has competed in the 2014 edition of the Targa Newfoundland race. Building a racing pickup is a dream for many, but it becomes a reality for very few. Bovey was therefore proud to be the first to compete in the Targa race with a pickup truck. The vehicle finished second in the classic vehicle division of that 2,200-kilometre-long rally race. Today, the Targa Truck is a custom chassis-equipped, carbon fiber front end-wearing, SDPC LS V8-powered monster that has seen many milestones and will see many more in the years to come. Among other things, Mark set his sights on driving up treacherous Mount Washington with the truck.

Since the original build of the truck is simply not aerodynamic, significant improvements in the output power of the vehicle have been implemented over the years, but everything has its limits. In order to further change the deal-given the limited resources at Bovey’s hand to bolster up the performance of his truck-technology had to come forth and allow for future development. Enter ACL Designs and Cyrious Garageworks.

ACL Designs provides 3D scanning and modeling services while Cyrious Garageworks specializes in race car preparation, fabrication, restoration, as well as maintenance. The former would provide the tools for the job, i.e., 3D laser scanning instruments and project management services, and the latter would manufacture the custom parts resulting from the analyses. What a great team effort!

When a Little Help Goes a Long Way

The goal of the whole scanning process was to design parts and components that would allow for the improvement of the aerodynamic performance of the truck. The actual scanning process was conducted by ACL Designs via Trevor Lichty, a man who has been scanning objects of all types and sizes for more than ten years. If you stop and think about it, Lichty has even worked on the scanning of an entire oil refinery. Apart from the usual obstacles such as lift arms and jack stands, the environment for Trevor’s task was fairly scanner-friendly, thanks to his expertise. Should the context had been less likely to host a scanning session, rest assured that Creaform scanners have seen rather uncommon environments.

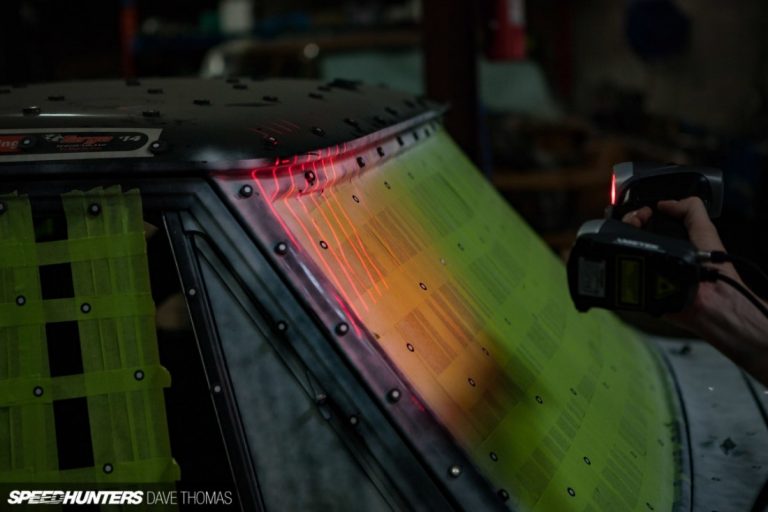

Firstly, the approach consisted in sticking hundreds of shiny dots on the vehicle, a means for the scanner to position itself in space. Green masking tape was then applied to bridge components and therefore highlight complex sections or yet to be filled space which would not be accounted for in the final 3D models. Moreover, removable white matte paint (affectionately nicknamed chalk-in-a-can by Trevor Lichty) was used to cover a fair amount of the exterior surfaces of the truck; 3D scanners generally do not cope up well with reflective materials since the reflections can blur the data.

Then started a 16-hour scanning marathon, approximately one three-foot section at a time, for the scanner has a volumetric accuracy of +/- 0.0015 inches over three cubic feet. To be noted: given the latest technological advancements in 3D scanning, the processing time is dramatically reduced, and chalk-in-a-can goes in the dust bin. Indeed, Creaform’s HandySCAN BLACK provides quick, accurate, and reliable measurements and can be used to capture data on black, shiny surfaces, without the need for any sort of primer, paint, or coating. Unfortunately, the HandySCAN BLACK was not used while scanning the Targa Truck… Nonetheless, the 16-hour task was worth the while with all that’s been done with the data afterward.

Data Is the New Oil

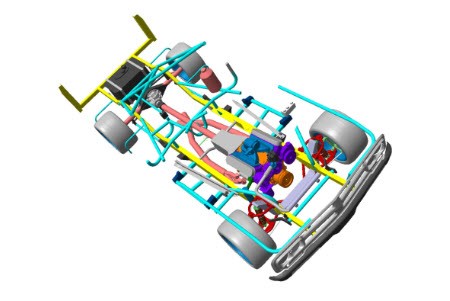

Using the models developed through the scanning process, the truck can be run through computational fluid dynamics (CFD) analysis, a.k.a. looking at how the air flows around the truck. And so, the results of the analysis can be used to create digital parts that make better use of the air that passes over, under and through the vehicle while it is in motion

Trevor Lichty uses two computers – with a build similar to that of a powerful gaming rig – to capture the scanned data and generate models that, although rudimentary, are precise 3D representations of the truck’s internal and external structure, including paint imperfections and gaps in the bodywork.

Another crucial company jumps in at that specific stage to answer Mark Bovey’s questions in regard to pressure zones and turbulence. Australian-based AeroDesign knows what works and what doesn’t with the use of airflow. Effective outcomes include providing downforce to the design and cooling the areas that need to be cooled.

The last step of the journey towards making the Targa Truck suitable for diverse situations consists of transforming the digital parts into real-world parts, and the staff at Cyrious Garageworks are on the case. Thus, Bovey can pick from the available resources, mix and match parts according to the application at hand, and pretty much make his dreams a reality.

More than just tools to digitally render three-dimensional models, 3D scanners and pertaining software help in various ways. Sometimes it means aero designing a truck for it to become a mountain-climbing race beast.

In brief, it’s easy to think of 3D scanning and metrology as a high-tech means for high-tech industries to engineer and inspect products and objects increasingly complex over time. But the reality is quite different: some projects are oriented towards personal fulfillment while others are aimed at making accurate data or historical information available to the public.

Trevor Lichty uses two computers – with a build similar to that of a powerful gaming rig – to capture the scanned data and generate models that, although rudimentary, are precise 3D representations of the truck’s internal and external structure, including paint imperfections and gaps in the bodywork.

Another crucial company jumps in at that specific stage to answer Mark Bovey’s questions in regard to pressure zones and turbulence. Australian-based AeroDesign knows what works and what doesn’t with the use of airflow. Effective outcomes include providing downforce to the design and cooling the areas that need to be cooled.

The last step of the journey towards making the Targa Truck suitable for diverse situations consists of transforming the digital parts into real-world parts, and the staff at Cyrious Garageworks are on the case. Thus, Bovey can pick from the available resources, mix and match parts according to the application at hand, and pretty much make his dreams a reality.

More than just tools to digitally render three-dimensional models, 3D scanners and pertaining software help in various ways. Sometimes it means aero designing a truck for it to become a mountain-climbing race beast.