As companies seek out new ways to create and innovate, they are constantly faced with unique demands each industry requires. This calls for a true variety of materials that can fit the job, no matter what challenge or stresses the produced parts run into!

The development of 3D printing technology has enabled the production and distribution of custom manufactured goods at an affordable price. Parts now have the capability to be customized to fit their end use with diverse materials including plastics, composites, and metals. Now, many industries using additive manufacturing in product development procceses to aid in rapid prototyping and even creating end-use products!

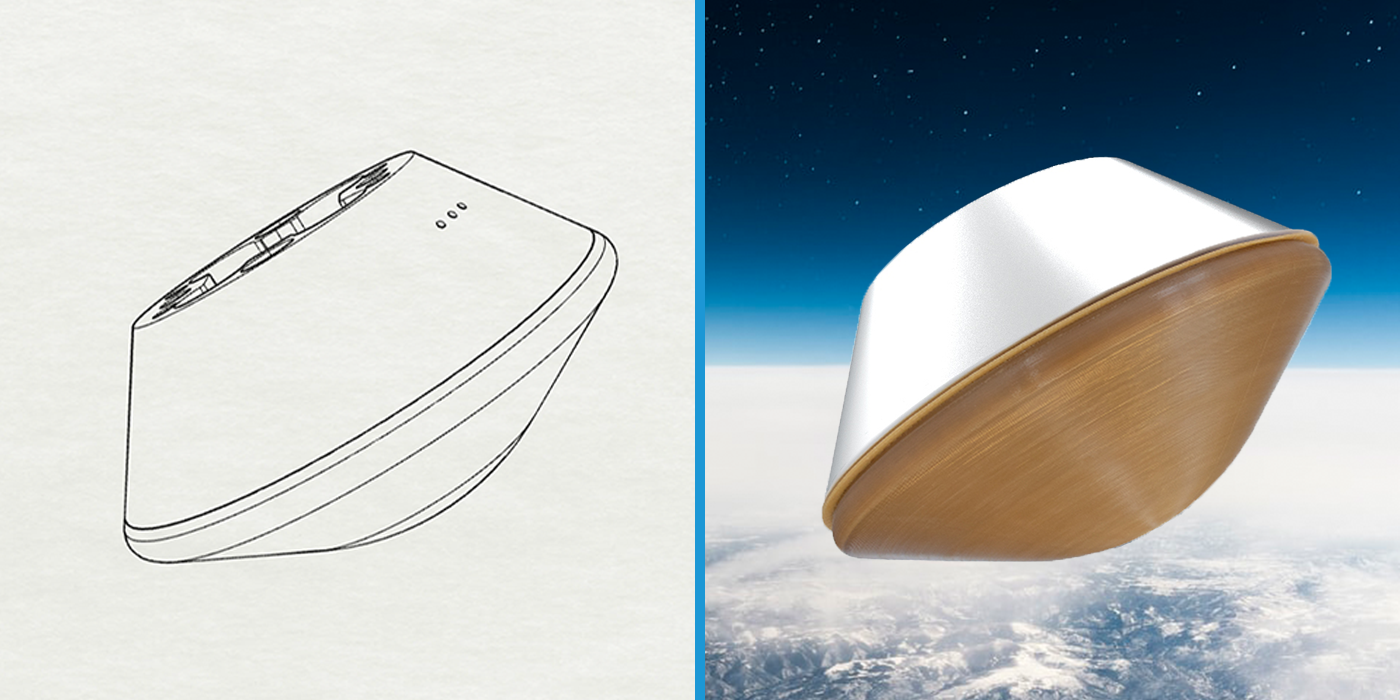

For instance, the redesigning for additive manufacturing of an antenna support arm for space satellite performed by OptiStruct and Altair Product Design teams at Altair Engineering showed a weight reduction of 50% using the correct suited material! Additive Manufacturing has been proven to be the best approach for optimizing the development and performance of a succesful part or product.

ACCURACY. DURABILITY. STRENGTH. PERFORMANCE.

The good news is that we are proven experts and authorized distrubutors/partners of these materials and 3D Printers! Our job is to make it easier for companies and users to adopt this next-level technology. Here are some key materials that we use daily to solve industrial product development and prototyping challenges:

ONYX

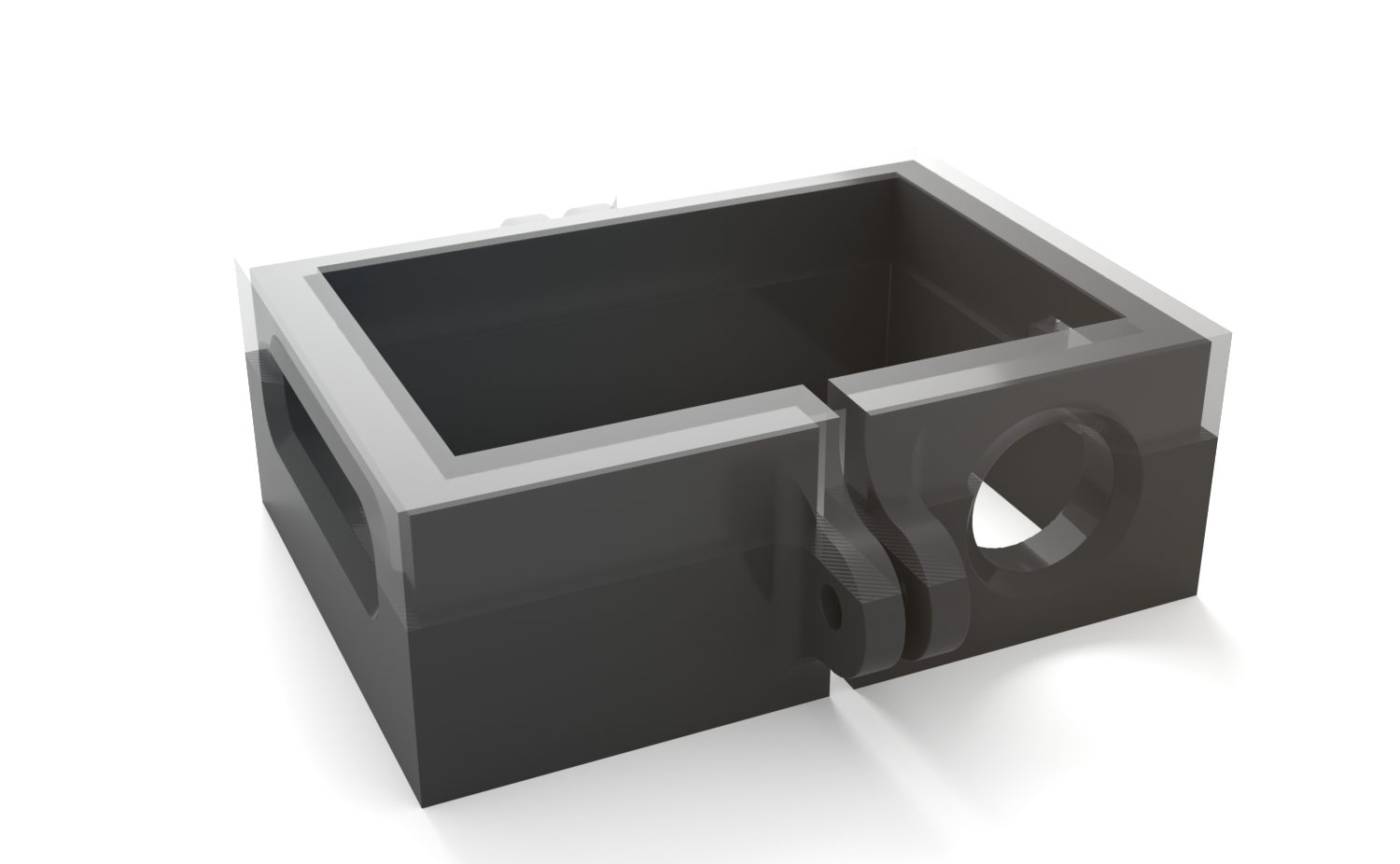

Onyx material is at the core of all Markforged printers starting with the Onyx One. It is a beautiful black filament made from combining tough nylon with micro-carbon reinforcement. Onyx gives you stiff and dimensionally stable engineering grade parts, with twice the strength of other 3D printed plastics. Onyx parts have a high quality surface finish and high heat tolerance.

Purchase your genuine Markforged Onyx Filament Material from Advantage 3D Solutions, a certified Markforged professional reseller.

Markforged Compatible 3D Printers: Onyx One, Onyx Pro, Mark Two, X3, X5, X7

High-strength thermoplastic with excellent heat resistance, surface finish, and chemical resistance.

Prototyping to End-Use Parts

Heat Deflection Temp: 145 °C

Yield Tensile Strength: 40 MPa

Tensile Strength: 37 MPa

Tensile Modulus: 2 GPa

Elongation At Break: 25 %

Density: 1.2 g/cm³

Impact Strength (ASTM): 330 J/m

ONYX CF

Onyx can be used alone, or further reinforced with embedded continuous carbon fiber, Kevlar, or fiberglass layers. This provides increased stiffness and a stronger print that can handle more stress under heavier or more challenging applications.

Markforged Compatible 3D Printers: Onyx Pro, Mark Two, X3, X5, X7

Stronger Results than ABS!

Reinforced with Carbon Fiber

Heat Deflection Temp: 105 °C

Corrosion Resistance: Excellent

Yield Tensile Strength: 800 MPa

Tensile Strength: 800 MPa

Tensile Modulus: 60 GPa

Elongation At Break: 2 %

Density: 1.4 g/cm³

Impact Strength (ASTM): 960 J/m

PRO HT

Temp Resistant. Biodegradable. Food Compliant. Dynamic.

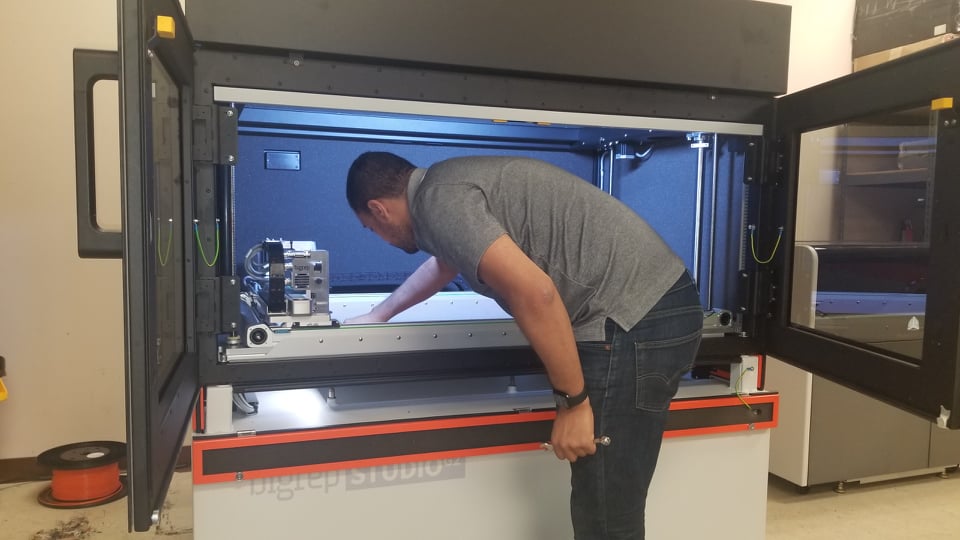

Large-Scale Capabilities

Resistant up to: 115 °C

Yield Tensile Strength: — MPa

Tensile Strength: 44 MPa

Tensile Modulus: — GPa

Elongation At Break: — %

Density: 1.3 g/cm³

Impact Strength (ASTM): 216 J/m

PEEK

PEEK (Polyetheretherketone) is considered as one of the world’s highest performing engineering thermoplastics, offering exceptional chemical resistance and excellent mechanical properties at high temperatures. Some of the main applications of PEEK in additive manufacturing include metal-replacement, functional prototyping, and end-use parts for industries like aerospace, automotive, oil and gas, medical, dental, and research.

INTAMSYS Compatible 3D Printers: FUNMAT HT, FUNMAT PRO 610HT

Exceptional chemical resistance and excellent mechanical properties at high temperatures

Lightweight & High-Strength

Heat Deflection Temp: —°C

Corrosion Resistance: Excellent

Yield Tensile Strength: 98MPa

Tensile Strength: 99 MPa

Tensile Modulus: 3 GPa

Elongation At Break: 24 %

Density: 1.3 g/cm³

Impact Strength (ASTM): 59 J/m

Get Started Today!

We are excited to help you get the most out of your application. If any of our materials, equipment, or services can assist with solving your manufacturing design challenges, feel free to reach out! With additive manufacturing still in its infancy, there are many challenges ahead for this technology to be realized at full potential.

Check Out Our Available 3D Printing Equipment