Learn how Additive Manufacturing has become an integral part of innovative companies!

The additive manufacturing process, also known as 3D printing has been gaining momentum! Here at NeoMetrix we specialize in the aerospace and automotive industry, but now this revolutionary technology is being adopted by even more sectors including marine, firearm, art/sculpture and more which allows us to have become experts in projects across all kinds of businesses. Download our exclusive eBook to learn more!

Solve Your Challenges with 3D Printing

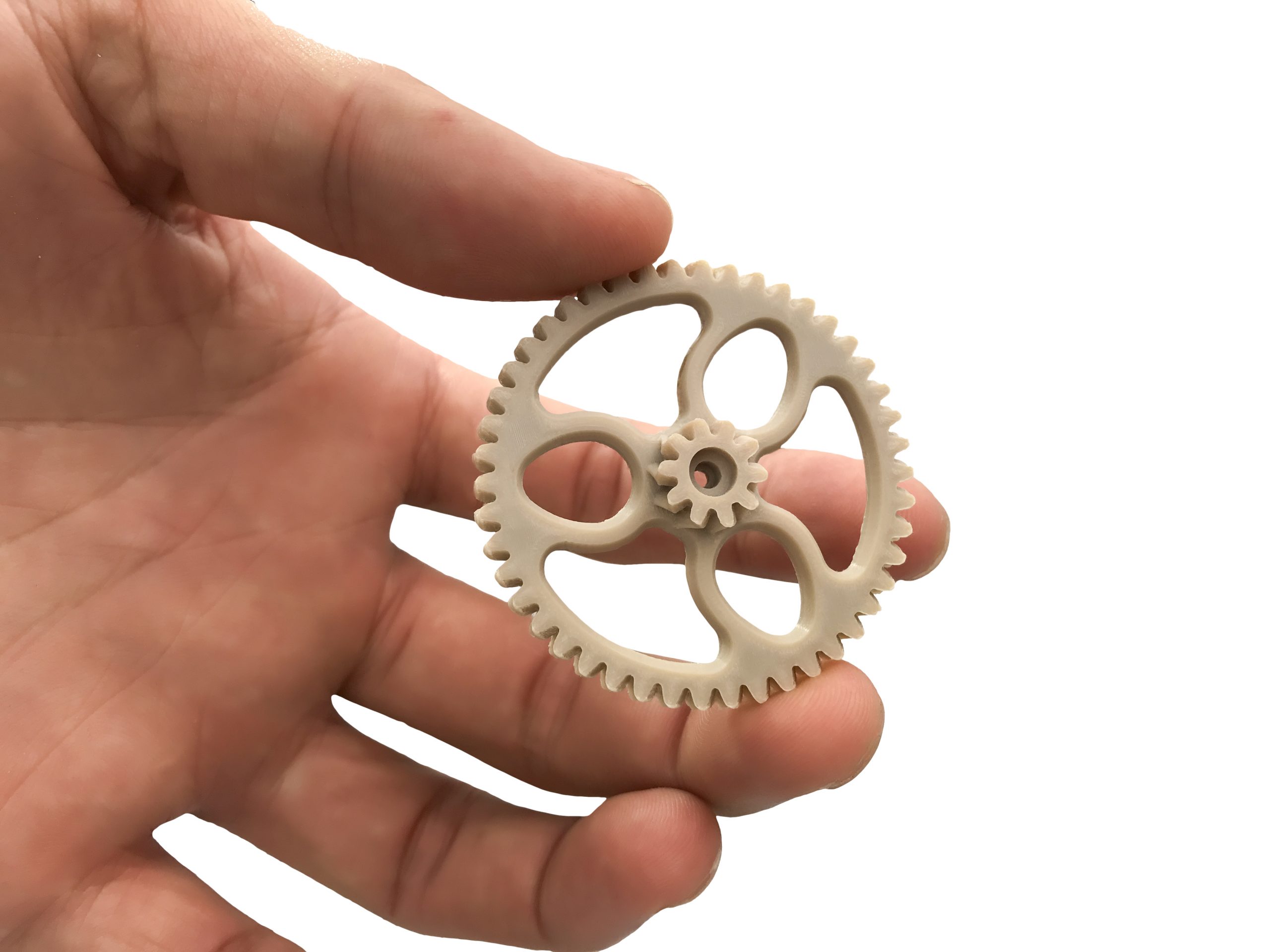

The first step of AM involves digitizing an object which can be done through either 3D modeling or 3D laser scanning direct physical models—to create a solid mesh which can be printed. In this step we first specialize in consulting/learning our clients challenges and details to ensure a successful print and fits the targeted application.

We then agree on an effective solution! Whether it’s integrating an industrial or desktop machine into your production process or we provide direct services to aid in any prototyping or product development cycle.

Let’s Connect

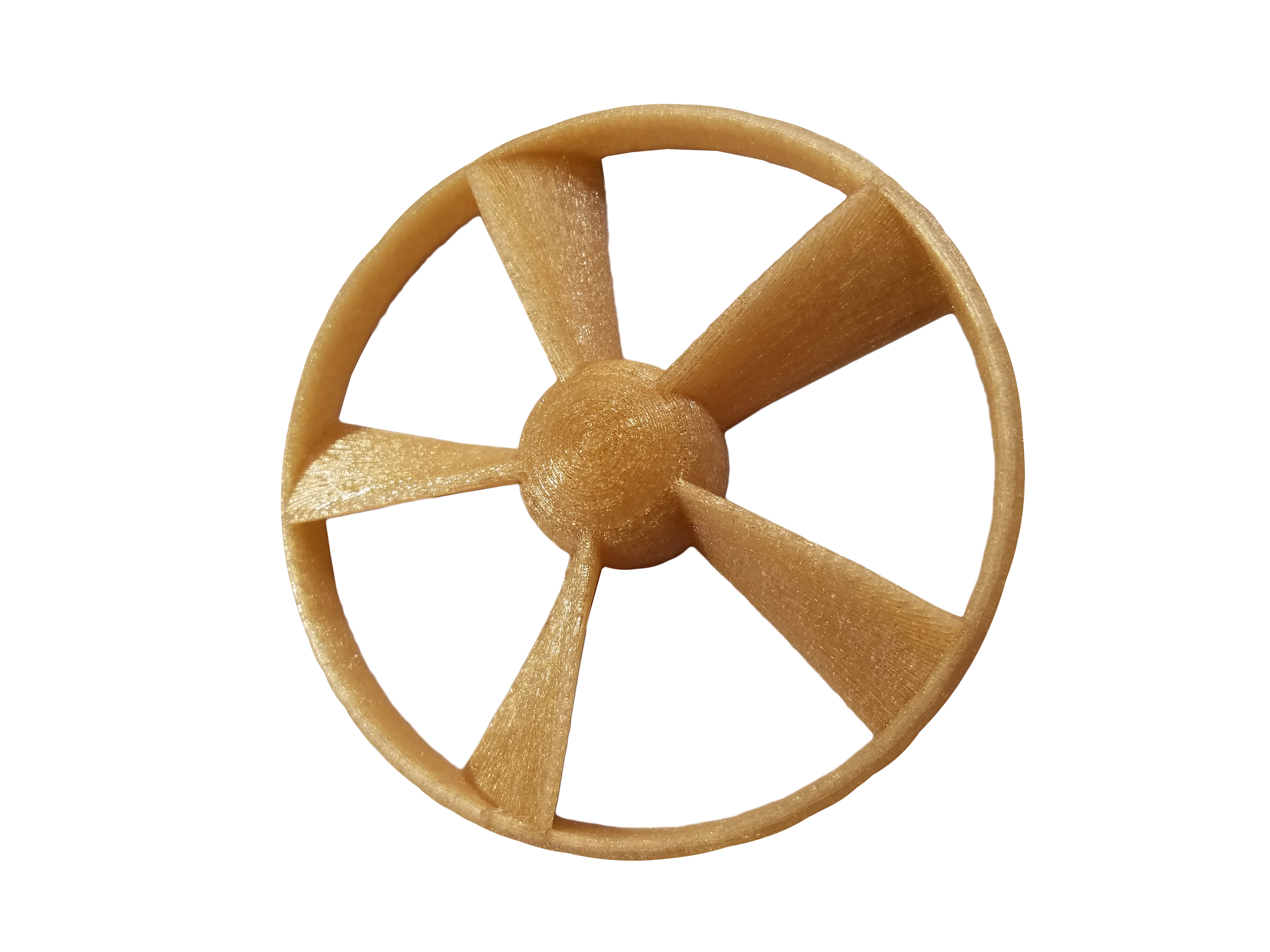

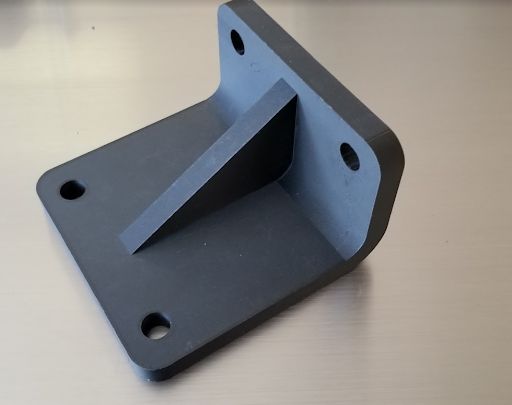

The benefits of using additive manufacturing to produce complex and simple parts are significant weight savings (20%+.), cost reduction, and improved turn around time. The technology also works well when it comes time for final production runs because of the ample amounts of high-performance materials that can be accessed to fit any application.

Additive manufacturing is an integral part of the company’s general strategic approach based on innovation and digital transformation.

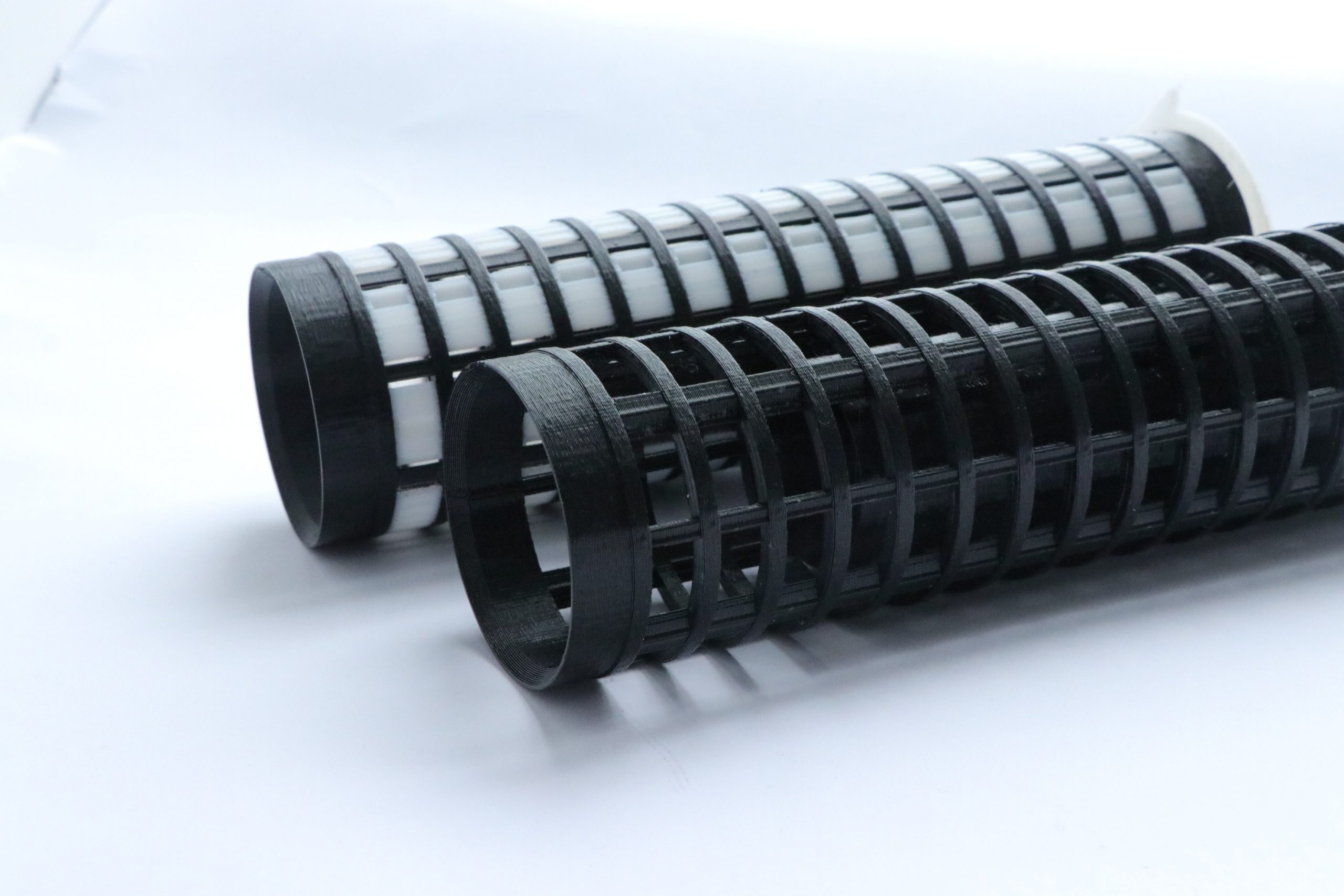

Composites

Technology: FDM/FFF

Max Build: 1000 x 500 x 500 mm (39 x 19 x 19 in)

Materials:

-

ProHT, PLA, HiTemp CF

-

Break Away & Soluble Supports

-

Other materials also available

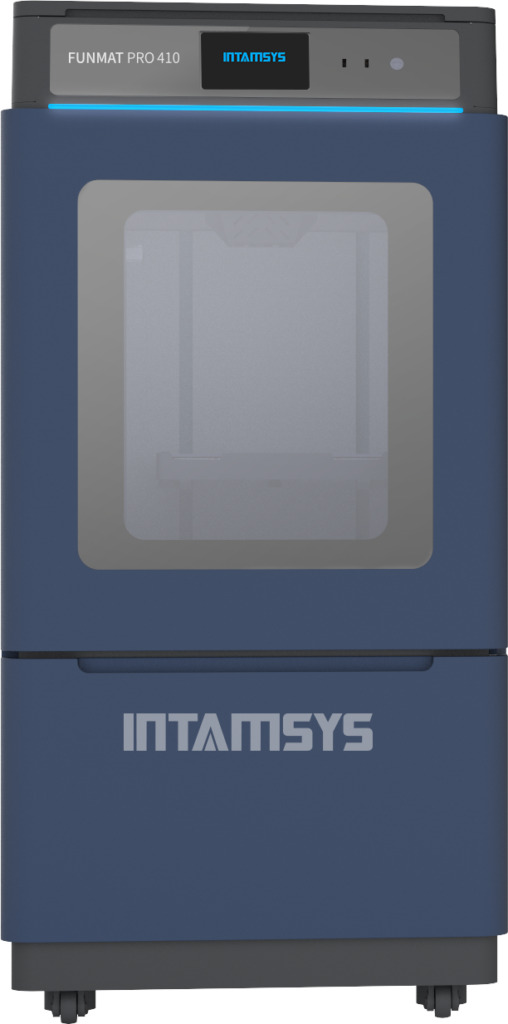

Composites

Technology: FDM/FFF

Max Build: 305 x 305 x 406 mm (12 x 12 x 16 in)

Materials:

-

ABS, PC, PLA, PA6, PA6 CF, PEEK, PEEK CF

-

Break away & soluble supports

-

Other materials also available

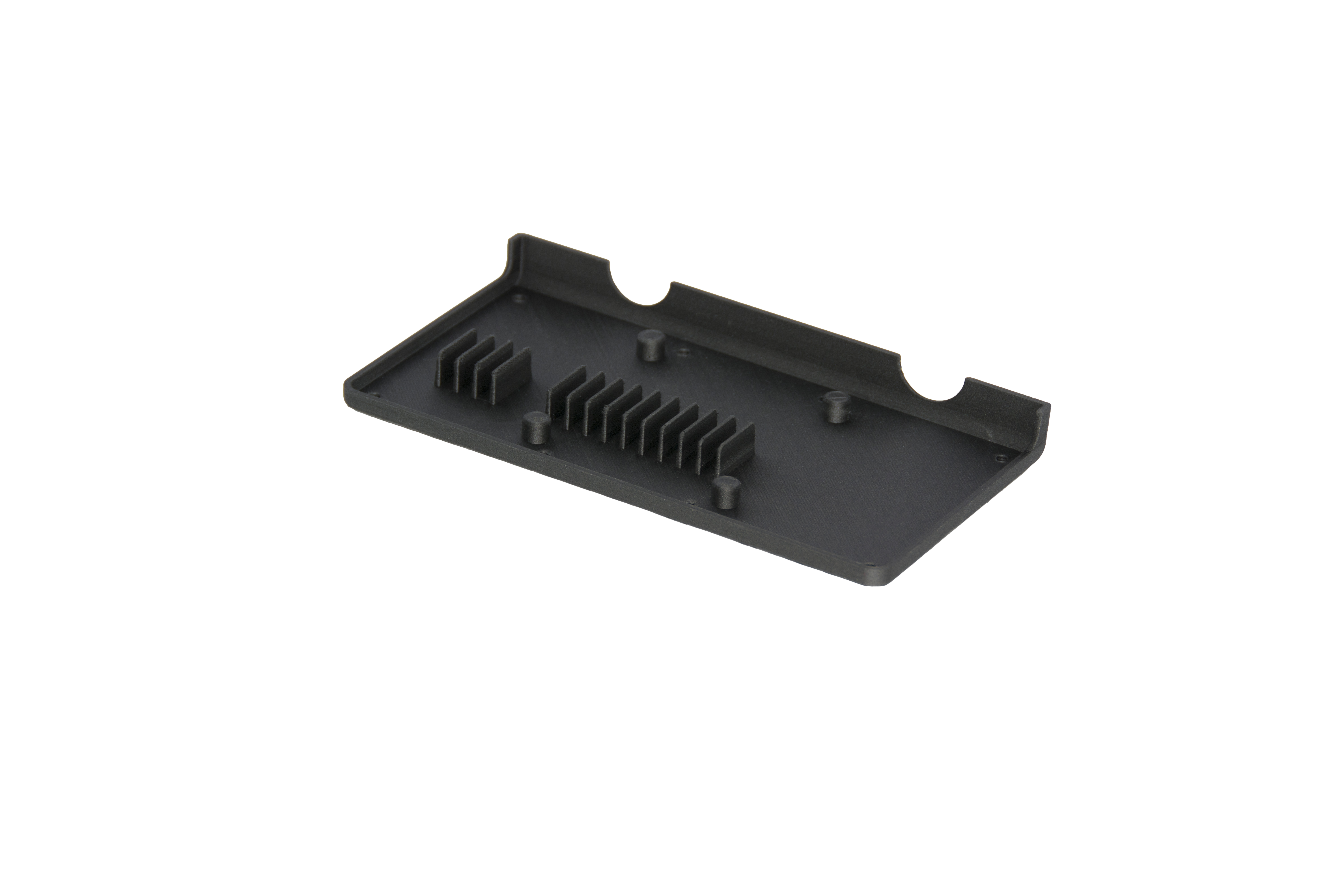

Composites

Technology: FDM/FFF

Max Build: 330 x 270 x 200 mm (13 x 10.6 x 7.9 in)

Materials: Onyx, Onyx CF

Metal

Technology: FDM/FFF

Max Build: 235 x 65 x 68 mm (9.25 x 2.7 x 2.6 in)

Materials: 17-4 Stainless, & Tool Steel

Technology: Multijet Modeling

Max Build: 294 x 211 x 144 mm (11.6 x 8.3 x 5.6 in)

Materials:

-

Acrylic Plastic: Visijet White & Clear

-

Polypropylene/ABS-Like: Visjet Armor

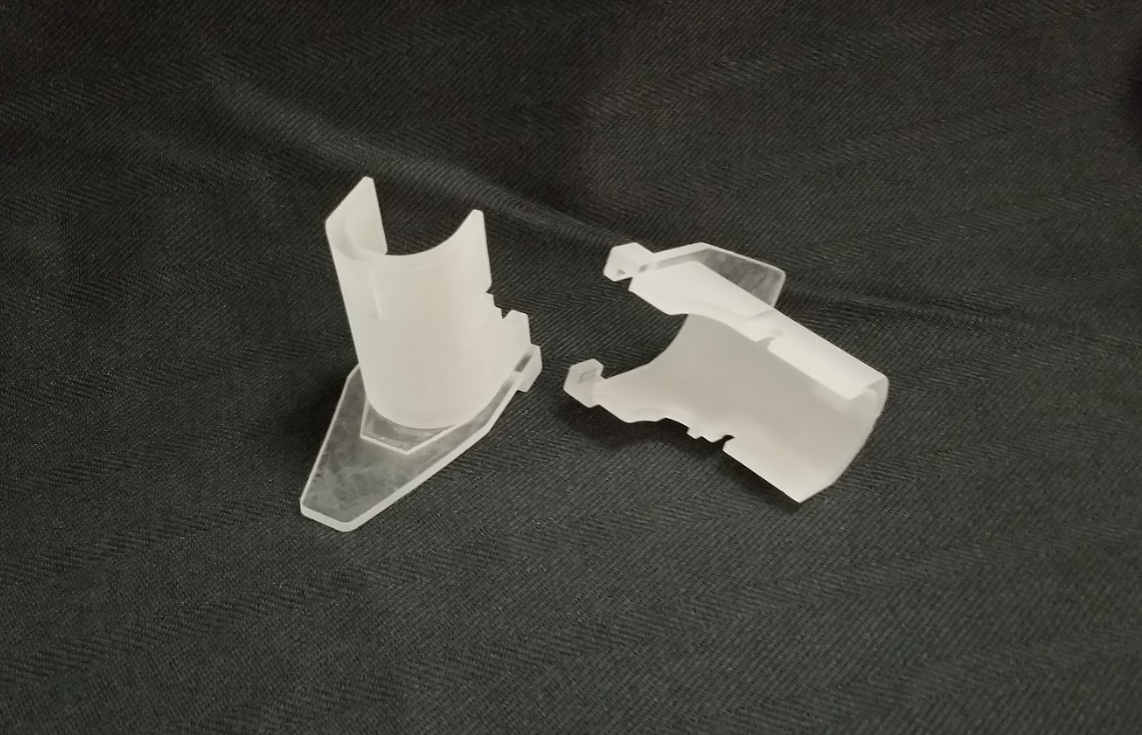

Medical Device Parts – Projet Visijet Armor

3D printing is a cost effective method to analyze your part designs before committing to the high cost of tooling development or the machining of production parts. NeoMetrix utilizes MultiJet, PolyJet, CFF, FDM, SLS and SLA technologies for 3D printing. Our 3D printers can produce parts in a variety of different photopolymer materials. Ultra fine layer thickness create accurate, clean, smooth and highly detailed 3-dimensional models for a variety of applications:

- Rapid Prototyping

- Concept Modeling

- Silicone Molding

- Additive Manufacturing

- Rapid Tooling

We have extensive experience working with a wide range of customers to help them produce the best possible product. Whether you’re looking for prototypes or end-use parts, we’ll do everything in our power make sure that your needs are met!

- Engineering-grade and chemical resistant materials to meet the requirements for your parts

- From Small high-resolution and detailed parts, to large-format functional parts

- Thousands of successfully printed parts for clients across various industries and still growing!

Available for YOUR INDUSTRY and APPLICATION!

PLUS MORE!

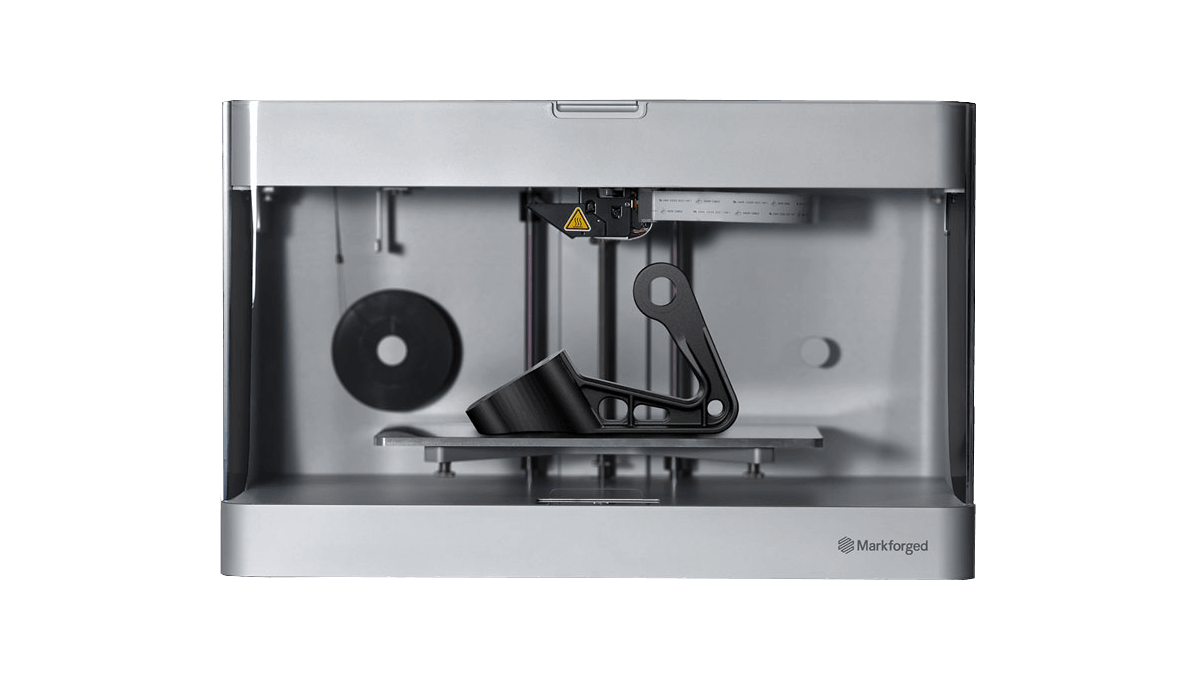

Check Out Our Available 3D Printing Equipment