Scan, Inspect, and Certify

In the aerospace industry, precision and compliance aren’t optional — they’re mission-critical. When tolerances are measured in microns and inspection requirements must be met quickly, traditional methods like fixed CMMs can slow production and drive up costs. That’s why aerospace leaders are turning to portable 3D scanning solutions to accelerate certification and maintain strict quality standards.

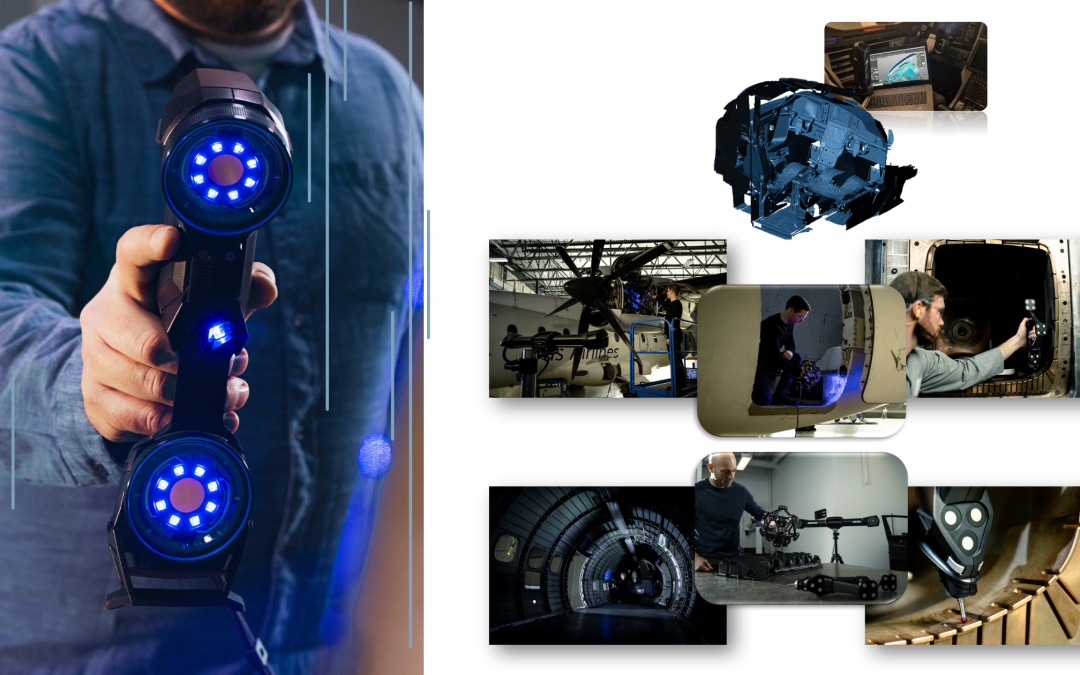

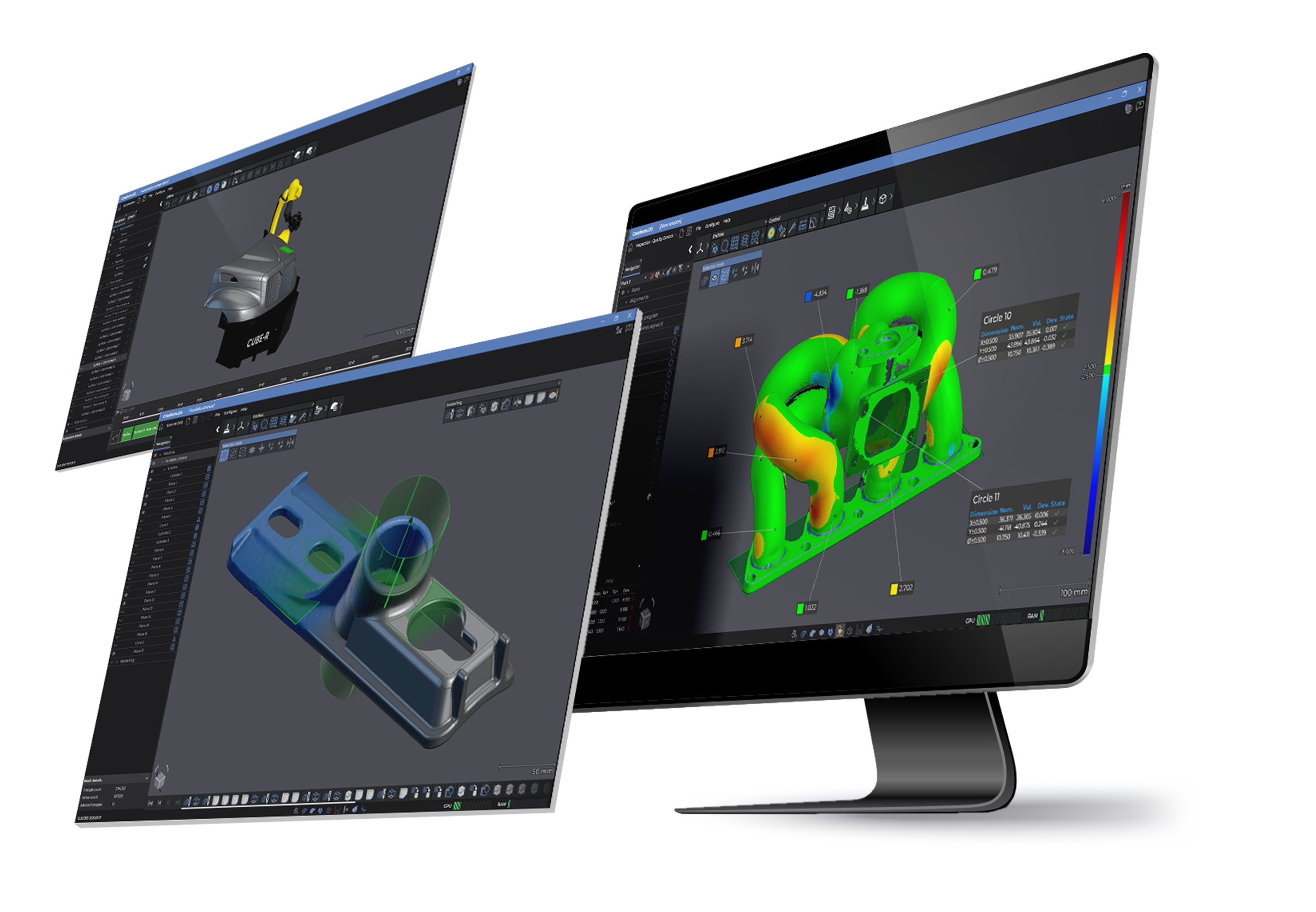

The HandySCAN Black + Elite is a trusted aerospace 3D scanning system, delivering metrology-grade accuracy with unmatched portability. Engineers and inspectors can capture accurate 3D data directly on the shop floor, in the hangar, or out in the field — making it an ideal portable CMM alternative for both production and MRO environments.

Key advantages for aerospace certification:

-

Capture fine details instantly — even on reflective, curved, or complex surfaces.

-

Streamline inspection workflows — reduce CMM dependencies and inspection bottlenecks.

-

Ensure compliance faster — meet your standards and ISO certification requirements with traceable, high-accuracy data.

Book a demo with NeoMetrix to see how Creaform HandySCAN can fit into your certification process!

Meet Aerospace Industrial Standards

From first article inspection (FAI) to ongoing MRO quality assurance, HandySCAN technology allows aerospace teams to shorten timelines, reduce rework, and eliminate uncertainty in the certification process.

NeoMetrix Technologies equips aerospace manufacturers, suppliers, and MRO providers with advanced 3D scanning solutions that improve efficiency, guarantee compliance, and maintain safety-critical standards. With the HandySCAN Black + Elite, aerospace organizations can accelerate certification — without sacrificing accuracy or reliability.

The Importance of Portable 3D Scanning in Aerospace

Portable 3D scanning plays a critical role in helping aerospace companies meet strict certification and quality standards. In addition:

-

It enables faster, more accurate inspections without the delays of traditional CMMs.

-

It supports compliance standards by providing traceable, repeatable measurement data.

-

It reduces downtime in MRO operations by allowing in-field scanning and validation.

-

It helps streamline first article inspections (FAI) and ongoing quality checks, ensuring long-term process improvement.

By integrating portable 3D scanning into inspection workflows, aerospace organizations can maintain compliance, accelerate certification, and improve efficiency across both production and maintenance operations.

When to Conduct a First Article Inspection (FAI):

-

First Production run of a new product

-

Design change

-

Manufacturing process change

-

Materials or sources change

-

Computer Program update affecting product form/function

-

After a lapse of more than two years’ production