Why engineers are choosing high-temperature additive manufacturing to stay competitive.

In every industry—automotive, aerospace, robotics, energy—one truth remains constant: product development never moves fast enough.

Engineers are under extreme pressure to deliver functional prototypes, iterate quickly, validate models, and transition into low-volume production without sacrificing performance or reliability. Yet traditional workflows leave massive gaps that slow down innovation.

Enter the FUNMAT PRO 310 APOLLO, a high-temperature additive platform engineered specifically to eliminate these bottlenecks. As PAEK-class polymers become mainstream replacements for metal, the APOLLO is quickly becoming the “go-to” system for teams who need high-performance parts right now.

Let’s break down the real challenges the APOLLO solves:

1. The Material Problem: “We Need Metal-Like Performance Without the Metal.”

Modern product development is shifting away from machined metal components—not because metal is weak, but because metal is slow, expensive, and restrictive.

PAEK-family polymers (PEEK, PEKK, and reinforced blends) offer:

-

High thermal resistance, Exceptional mechanical strength, Chemical/environmental stability, Lightweight performance

How APOLLO Solves It:

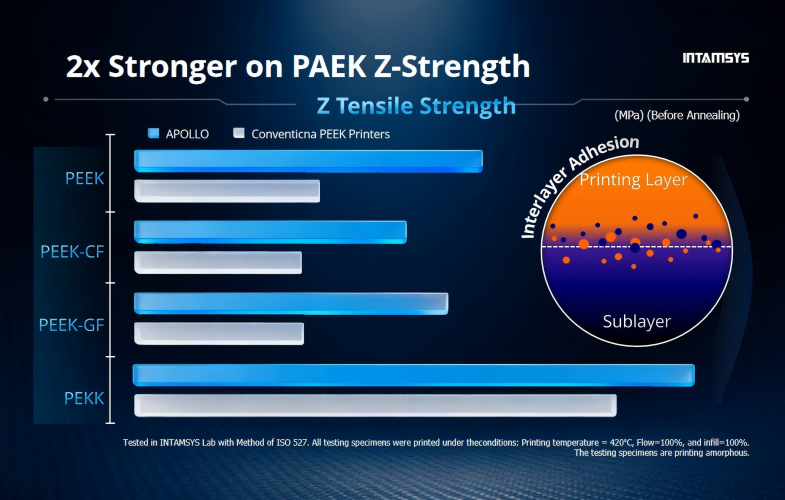

The APOLLO is built specifically for PAEK-grade processing. Its tightly managed thermal environment, high-temperature extrusion, and stable chamber conditions make it one of the only systems that can consistently deliver full-strength, production-ready PAEK parts.

2. The Bottleneck of Slow Iteration Cycles

Waiting days—or weeks—for tooling, fixturing, or prototype machining kills momentum in engineering workflows.

How APOLLO Solves It:

The APOLLO’s high-speed, high-temp architecture allows teams to produce strong, functional prototypes in hours instead of days.

Faster iterations = faster validation = faster time to market.

3. The Challenge of Scaling from Prototype to Production

Many printers are great at prototyping… right up until you need consistency, accuracy, or repeatability in production.

How APOLLO Solves It:

The APOLLO is engineered for:

-

Short-run batch manufacturing

-

Continuous printing cycles

-

Dimensional repeatability

-

Multi-material workflows (IDEX)

It bridges the gap between prototype and production, allowing engineers to validate and manufacture on the same platform.

High-temperature product development brings a trio of headaches: reliable support structures, long-duration printing stability, and complete process documentation. Most printers struggle to maintain dimensional accuracy when combining dissimilar materials, especially at elevated temperatures. On top of that, multi-day production jobs often fail due to moisture intrusion, inconsistent chamber temperatures, or filament degradation. Then comes the modern expectation of manufacturing traceability—engineers need more than a finished part; they need a verifiable process history. The FUNMAT PRO 310 APOLLO tackles all three.

With an independent dual-extrusion system, engineers can pair optimized high-temperature support materials with reinforced PAEK polymers for cleaner geometries and more accurate builds. Its advanced thermal management and controlled material storage enable truly uninterrupted high-temperature printing, even on multi-day cycles. And with integrated monitoring and job-logging tools, the APOLLO delivers the traceability required for aerospace, automotive, and production-scale environments—ensuring every part is as accountable as it is strong.

APOLLO Gives Engineers a Competitive Edge

The FUNMAT PRO 310 APOLLO is more than a printer—it’s a problem eliminator.

It accelerates iterative design, unlocks advanced materials, expands production capabilities, and provides engineers the flexibility to innovate without barriers.

NeoMetrix delivers the APOLLO with full engineering support, training, and integration services so your team can build stronger, lighter, smarter products—faster.

Need 3D Printing Services? We’ve got you covered!

Key Features

| Build volume | Single Extruder: 305 × 260 × 260 mm Dual Extruders: 260 × 260 × 260 mm |

| Print speed |

Up to 200 mm/s (optimized for high-temp engineering materials) |

| Extruder |

Independent Dual Extrusion (IDEX), high-temperature capable |

| Certified materials |

Full PAEK family: PEEK, PEKK, PAEK-CF, PAEK-GF + engineering polymers (ABS+, ASA, PC, PA12-CF, PPS, PPS-GF, TPU, support materials) |