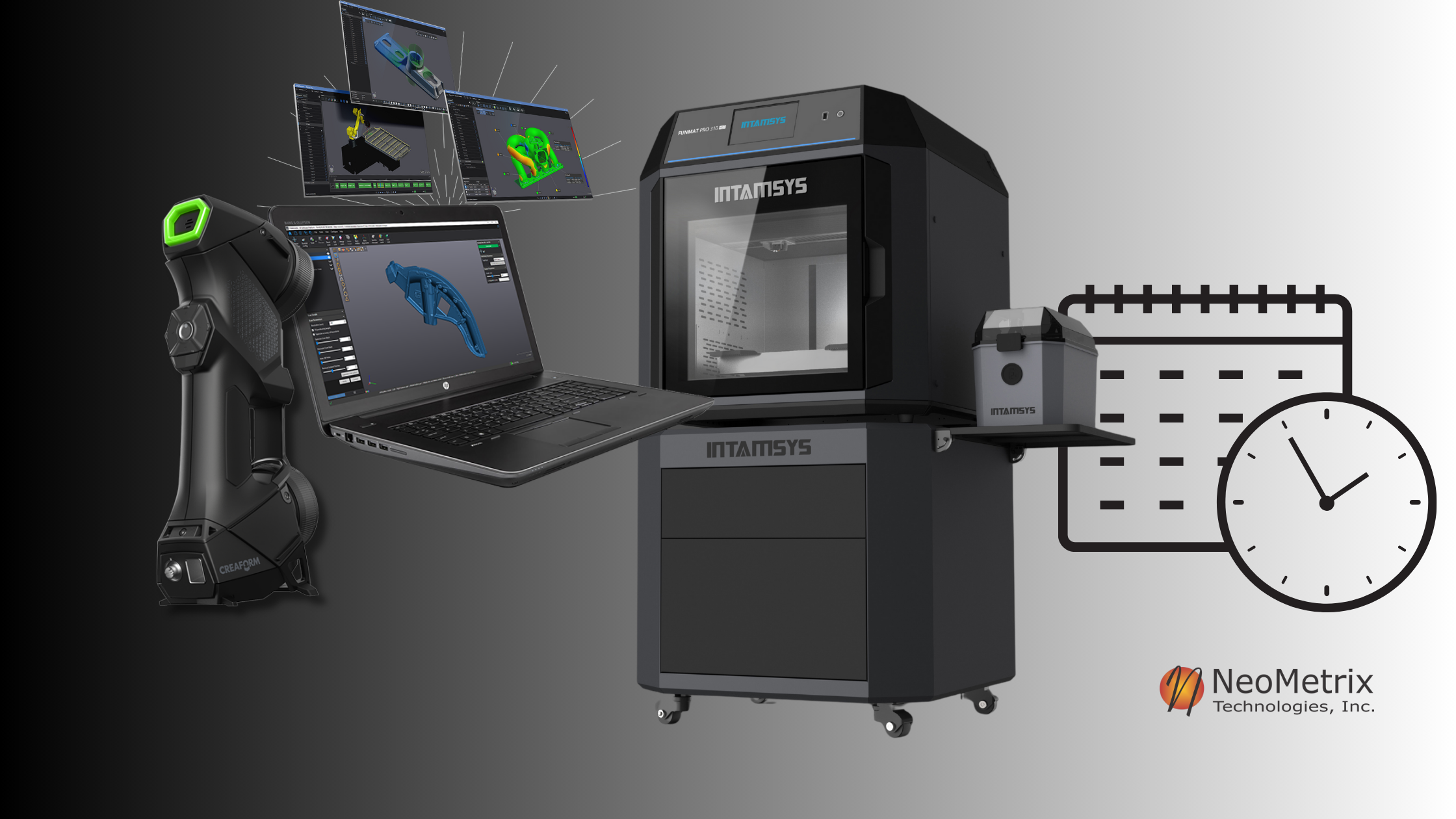

3D scanning is most powerful when it enables a complete digital product development and manufacturing process:

Scan → CAD → Inspection → Production.

NeoMetrix supports each stage, ensuring accuracy and alignment from the physical part to the engineered model and final manufactured result.

By integrating this technology into a complete, end-to-end workflow businesses and product developers are able to accelerate design, prototyping, and manufacturing. In this blog, we’ll discover how 3D Scanning works, and how you can use it to your advantage.

Why This Process Matters

3D scanning preserves the exact geometry of critical components, even when original drawings or CAD models are unavailable. This digital foundation allows teams to redesign, validate, reproduce, or improve parts with precision and confidence. It also supports faster development cycles and reduces rework by eliminating guesswork during design and manufacturing.

Many SOLIDWORKS users and 3D modelers find that integrating 3D scanning dramatically reduces modeling time, because the scan provides exact reference geometry to build clean, accurate CAD features without guesswork.

Step 1: Capture Surface Data with 3D Scanning

The process begins by digitizing the physical part using a high-precision 3D scanner. The scanner projects structured light or laser patterns across the object and records millions of surface measurements to generate a highly accurate point cloud or mesh model. This provides a true-to-form digital representation of every curve, edge, and contour

This stage is critical because the quality of the scan directly influences every step that follows. Surfaces must be captured with clarity and consistency, especially on complex geometry or parts that will be manufactured to tight tolerances. The right scanner, proper setup, and skilled scanning technique ensure the data is accurate, complete, and free from distortion.

At NeoMetrix, we use metrology-grade scanning systems and expert application engineers, ensuring the foundation of the digital model is solid — which is essential for delivering reliable design, inspection, or production results later in the workflow.

Watch a complete 3D scanning Demo of an aircraft propeller!

Step 2: Engineer Converts 3D Scan Data to a CAD Model

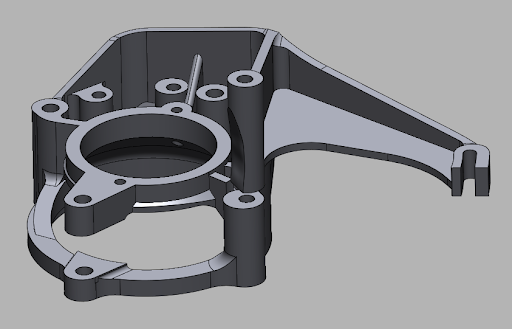

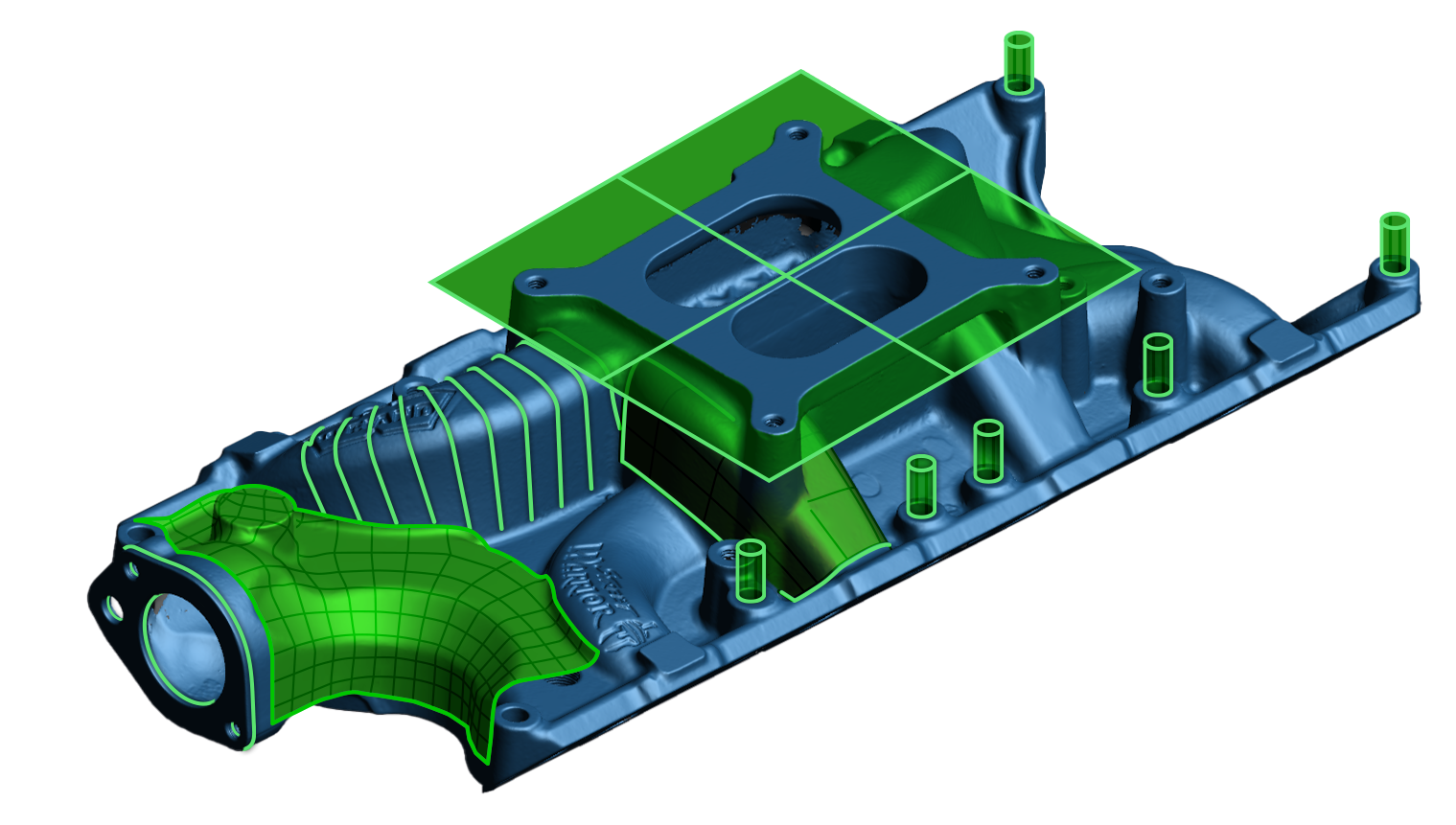

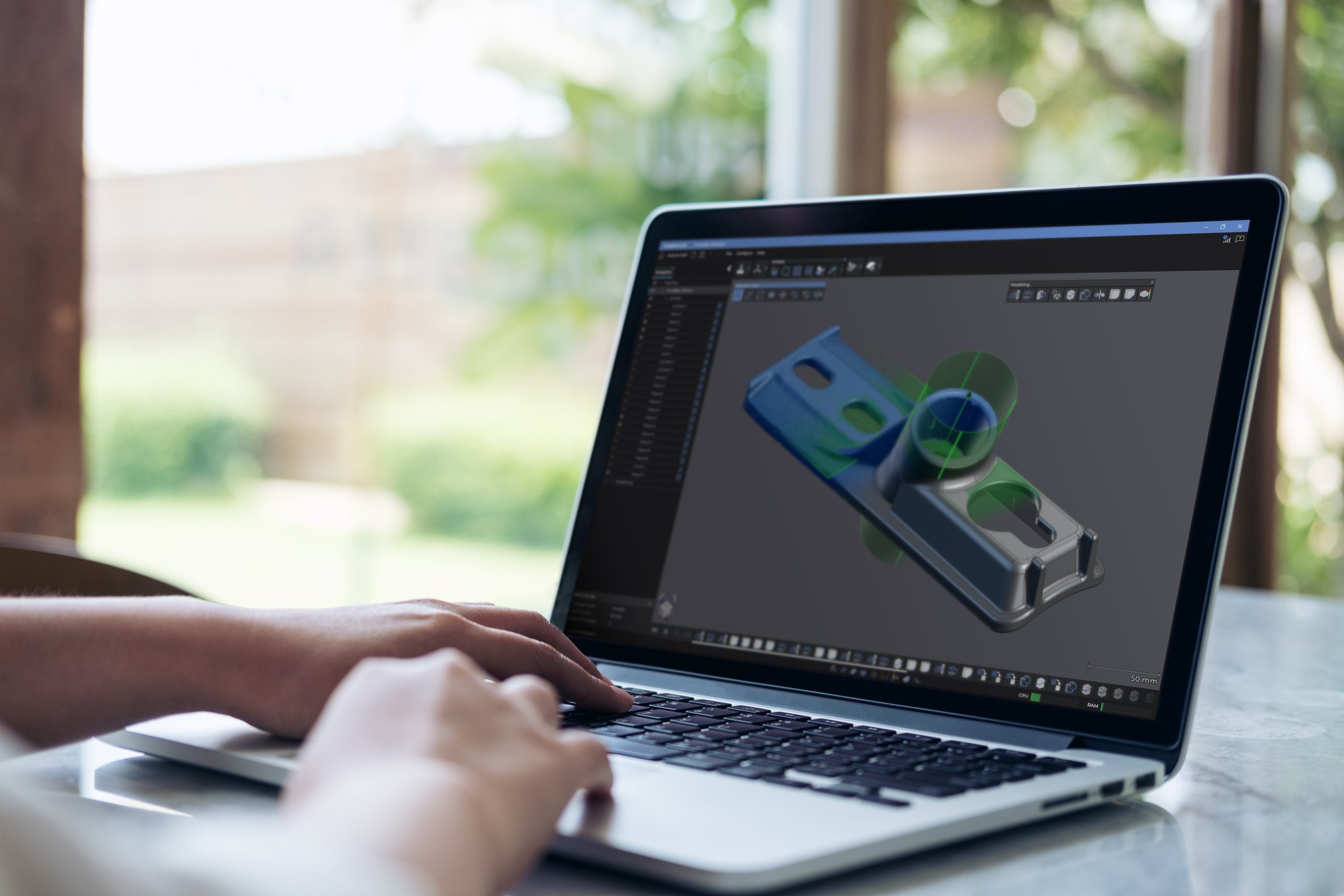

Using reverse engineering software like Geomagic Design X, an engineer transforms the scan data into a clean, editable CAD model. This allows you to modify, redesign, optimize, or reproduce the part with full control and accuracy.

Once the scan data is captured, the next stage is where engineering skill and human intuition play a central role. Using advanced reverse engineering software such as Geomagic Design X, an engineer interprets the point cloud and reconstructs it into a clean, fully parametric CAD model.

This is not an automated process. It requires judgment, experience, and an understanding of how the part functions in the real world. Curves, mating features, tolerances, and design intent must be carefully re-created to match both the original geometry and the performance requirements of the final application.

Because of this, the modeling stage is one of the most valuable components of the entire workflow. It is what allows the scanned part to move beyond being a digital copy and become a precise, editable design ready for production, modification, or optimization.

Watch a complete Reverse Engineering Demo of an aircraft propeller!

Once the 3D scan data is captured, it is imported into Geomagic Design X, a leading reverse engineering software used for converting mesh or point cloud data into fully parametric, feature-based CAD models. Using tools for surface fitting, feature extraction, and design intent reconstruction, the engineer rebuilds the geometry into editable CAD features such as planes, fillets, holes, ribs, and mounting surfaces.

This process allows the scanned object to be opened and modified in standard CAD platforms like SolidWorks, Siemens NX, Creo, Inventor, or CATIA, enabling accurate part redesign, manufacturing, prototyping, and quality validation. This is often referred to as Scan-to-CAD, and it is essential when original drawings or models are unavailable, outdated, or inaccurate.

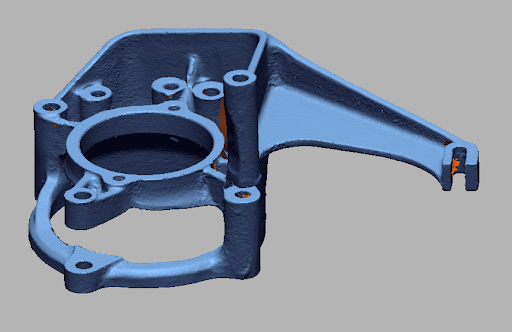

Original/Legacy Part

-

Legacy and out-of-production parts

-

Tooling and fixture recreation

-

Product design and prototyping

-

Fitment verification for aftermarket parts

-

Quality control and inspection / Wear and damage analysis

-

Aerospace/Automotive/Marine component redesign

Complete 3D Scan

High-Precision Surface Capture with Accurate Point Cloud Data using Creaform 3D Scanners

Convert to CAD using:

Converted to CAD Using Geomagic Design X – Feature-Based Reverse Engineering for Parametric Modeling and Manufacturing

Scan-to-CAD PRO – Available with Creaform.OS

Scan-to-CAD Module

Transform 3D scan data into accurate CAD models quickly and efficiently.

The Scan-to-CAD module streamlines reverse engineering, allowing seamless integration into design and manufacturing workflows.

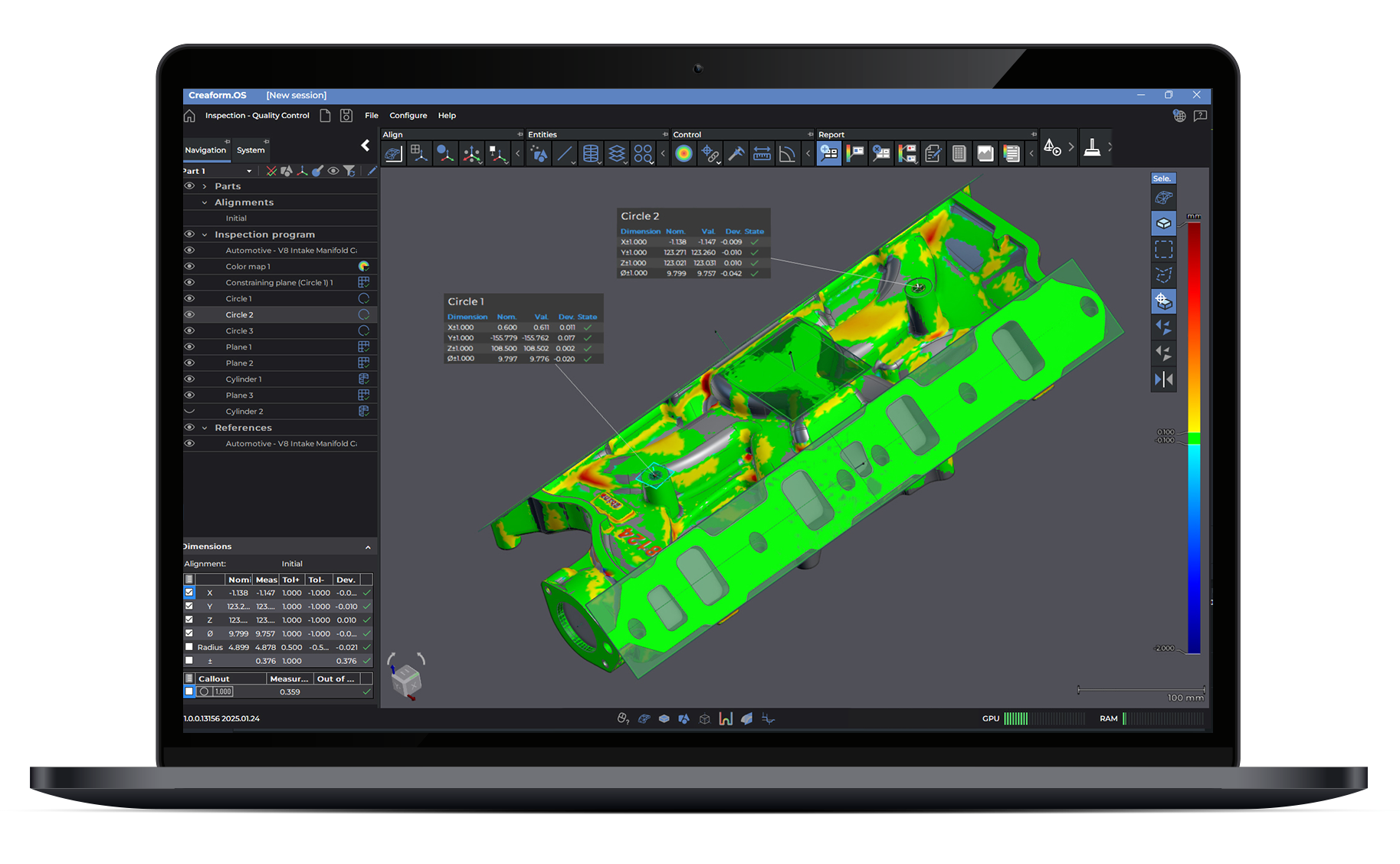

Inspection Module

Ensure quality control and compliance with high-precision inspection tools.

The Inspection module provides detailed dimensional analysis, helping detect deviations and maintain manufacturing standards with confidence.

Step 3: Go from digital to physical production

Once the CAD model is ready, the design can be manufactured. With industrial 3D printers, we can produce functional prototypes, tooling, and end-use parts directly from that digital file.

Go Further: Inspect and Improve

3D scanning is also powerful for evaluating wear, quality, or damage. Using Geomagic Control X, we compare a scanned part to its original CAD model to identify deformation, degradation, or manufacturing variations. This is ideal for maintenance, repairs, or validating production accuracy on EXISTING parts in use.

Reproduce & Replace

If a part is worn, out-of-production, or needs customization, we can scan it, redesign it, and 3D print a replacement quickly and efficiently.

Complete Cycle for Production and Manufacturing

This complete workflow ensures you are not just capturing geometry, but turning real-world parts into fully functional digital assets. Whether you are restoring a legacy component, improving an existing design, or producing new parts through additive manufacturing, NeoMetrix provides the tools and expertise to move seamlessly from scan data to CAD, to finished part. Our team supports every step of the process so you can accelerate development, eliminate guesswork, and maintain the highest level of precision in your product lifecycle.

Combined with the wide range of industrial applications—from aerospace to automotive to consumer manufacturing—this level of expertise is what makes NeoMetrix a leading resource for organizations that require accuracy, repeatability, and professional-grade engineering results

PARTNER SUCCESS STORIES

If you have a part you need to reproduce, improve, or document, our team can review your application and recommend the best scanning and reverse engineering approach. Send us a quick note with your project goals to get started.