Explore marine-grade 3D printing materials and systems from NeoMetrix. Produce durable, corrosion-resistant components with VIIO, BigRep PRO & FUNMAT PRO 310NEO.

The marine industry faces unique engineering challenges—harsh saltwater environments, demanding structural requirements, and the need for both lightweight and durable components. From shipbuilding to offshore structures, the right manufacturing technology can mean the difference between costly downtime and long-term performance.

Why 3D Printing in Marine Applications

- Speed & Flexibility – Produce custom parts, jigs, and fixtures on-demand without the long lead times of traditional manufacturing.

- Design Freedom – Create complex geometries for optimized hydrodynamics and weight reduction.

- Material Performance – Leverage high-strength, corrosion-resistant polymers for extended part life in marine environments.

Suitable 3D Printing Materials for Marine Use

Our industrial systems print a range of materials ideal for marine components, including:

-

ASA – UV and weather resistant, great for topside parts exposed to sunlight

-

PA-CF / PA-GF – High mechanical performance with resistance to impact and moisture absorption.

-

PETG – Strong, lightweight, and resistant to water exposure—perfect for enclosures and fixtures.

- BigRep ProHT – Perfect for prototyping. The material can be used to quickly create functional prototypes, such as models of propellers or hulls, allowing engineers to test and refine designs before committing to final production.

Industrial 3D Printers for Marine Applications

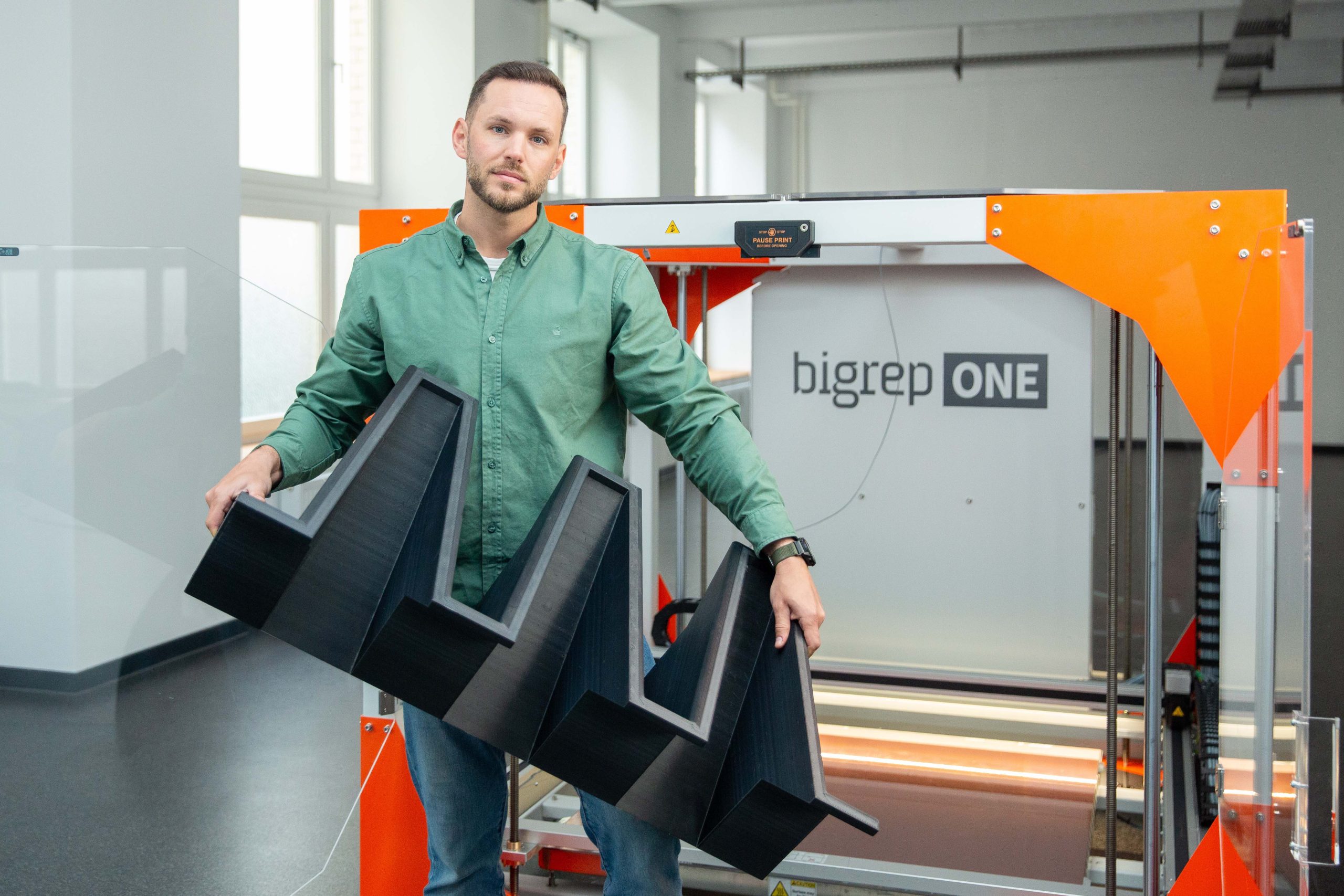

BigRep VIIO 250

Large-format printer for producing full-scale marine components, molds, or fixtures. Perfect for hull sections, seating, and custom housings.

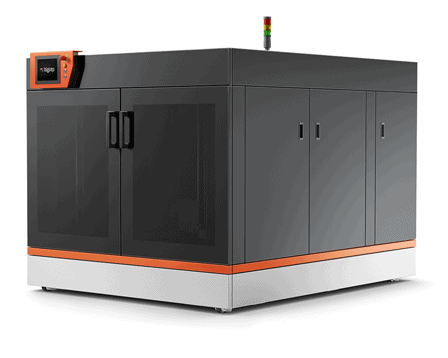

BigRep PRO –

Advanced large-scale system with engineering-grade material compatibility, ideal for tooling, jigs, and large end-use parts.

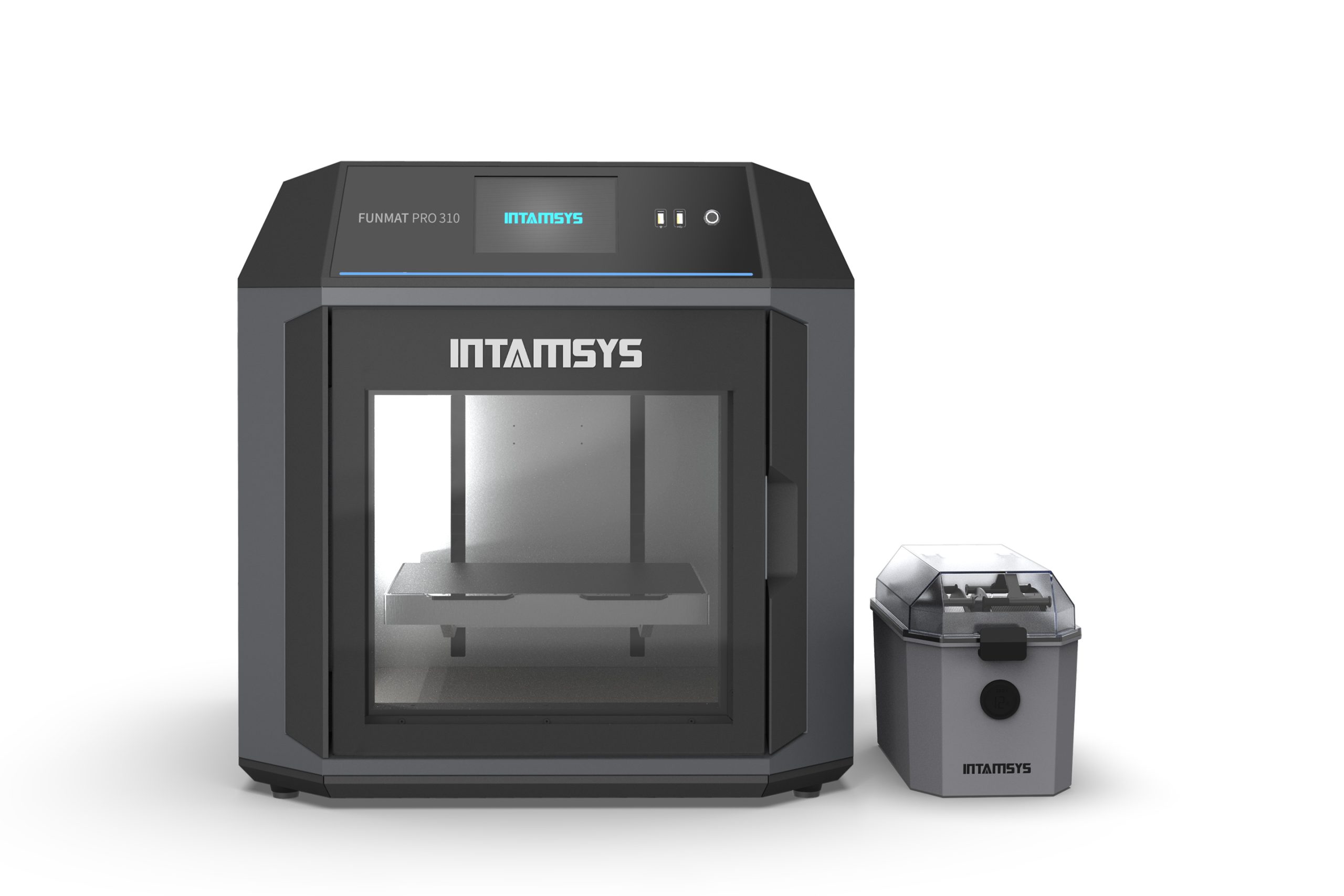

FUNMAT PRO 310NEO –

High-performance printer for engineering polymers providing the chemical and thermal resistance needed for marine-grade components.

Real-World Marine Applications

-

- Molds and tooling: Creating molds for composite lamination of custom boat parts and structures. This reduces the time and cost associated with traditional mold-making.

- Custom end-use components: Customized parts for boats and yachts, including non-structural interior fixtures, air ducts, covers, and custom brackets.

- On-demand spare parts: For large vessels, including military and commercial ships, 3D Printing can be used to print replacement parts like fittings and covers on-site. This reduces logistical costs and the need to carry large physical inventories.

- Underwater applications: Suitable for creating custom enclosures and parts for autonomous underwater vehicles, as tested by companies collaborating with

Newsfender EU Launches 3D Printed, Sustainable Boat Fenders

The Spain-based company has introduced marine fenders 3D printed from TPU with a “return and recycle” concept.

Original Source: http://additivemanufacturing.media/articles/newsfender-eu-launches-3d-printed-sustainable-boat-fenders

Maximize ROI with Section 179

All of these printers qualify for Section 179 tax deductions, allowing your business to deduct the full purchase price of eligible equipment in the year it’s placed into service. Invest now to upgrade production capabilities and reduce your tax burden before year-end.

Ready to modernize your marine component production?

Contact NeoMetrix Technologies today to discuss your application and see how industrial 3D Printing solutions can accelerate your design-to-production cycle.