THE PROBLEM

Outdated, Damaged, and deteriorating panel needing replacement. This part is no longer manufactured!

Fully restored and perfectly fit part created with NeoMetrix’s unique services and capabilities.

TRADITIONAL METHOD

Without 3D scanning technology, this task is virtually impossible. Maybe some cardboard templates could be manually fit, or hand fitting some ABS sheeting to simply cover the holes.. but the fit and finish would be terrible.

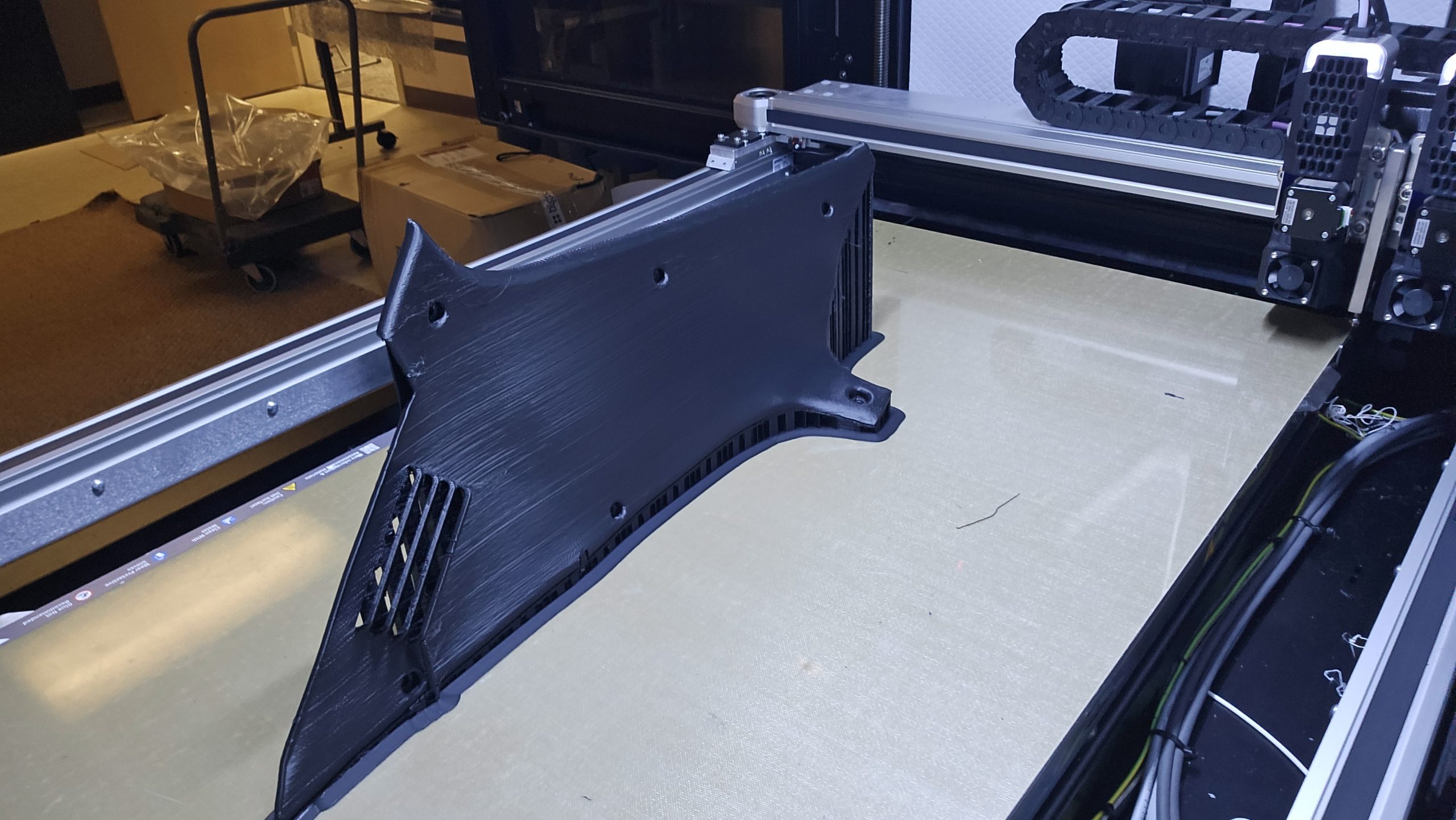

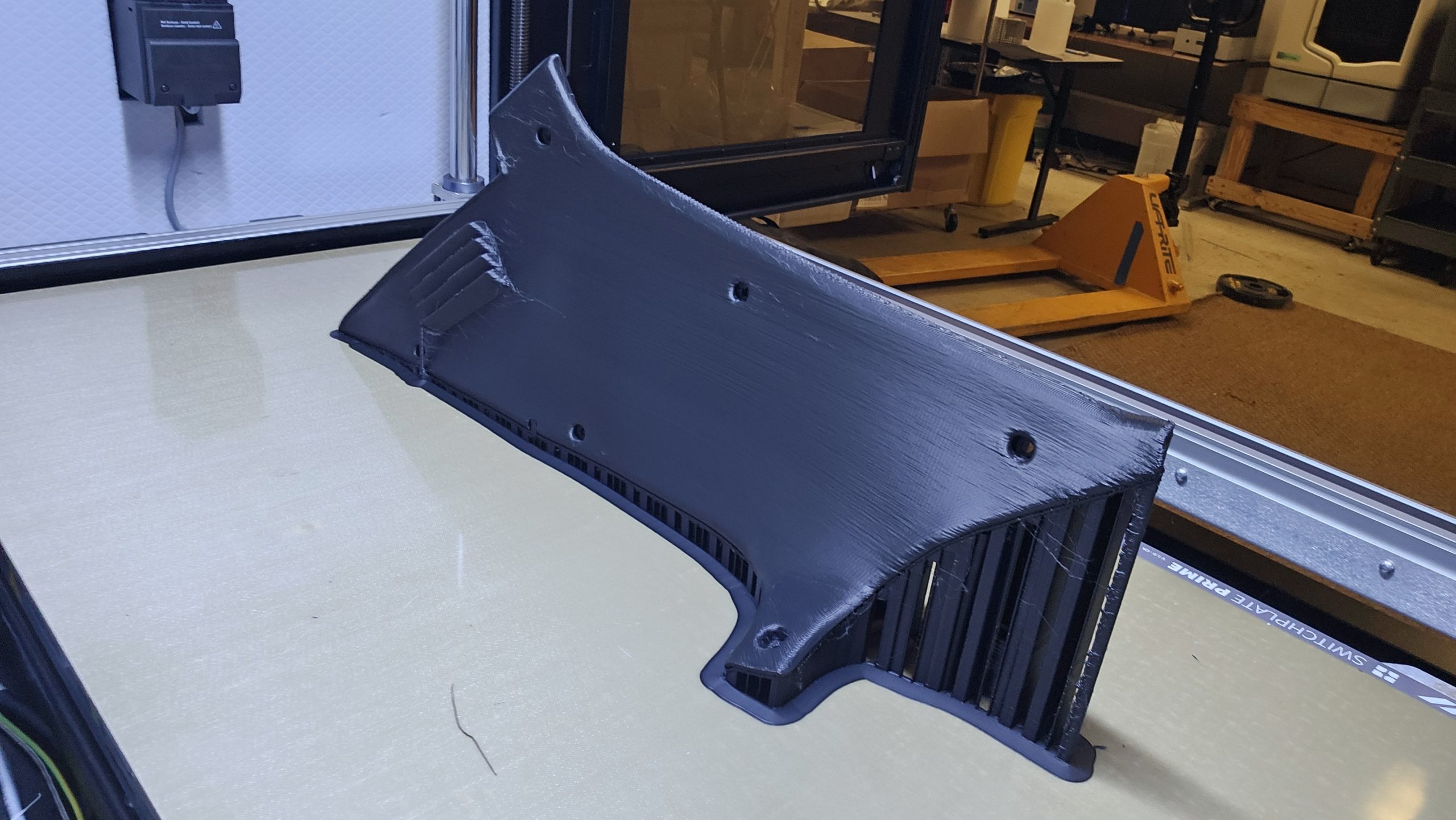

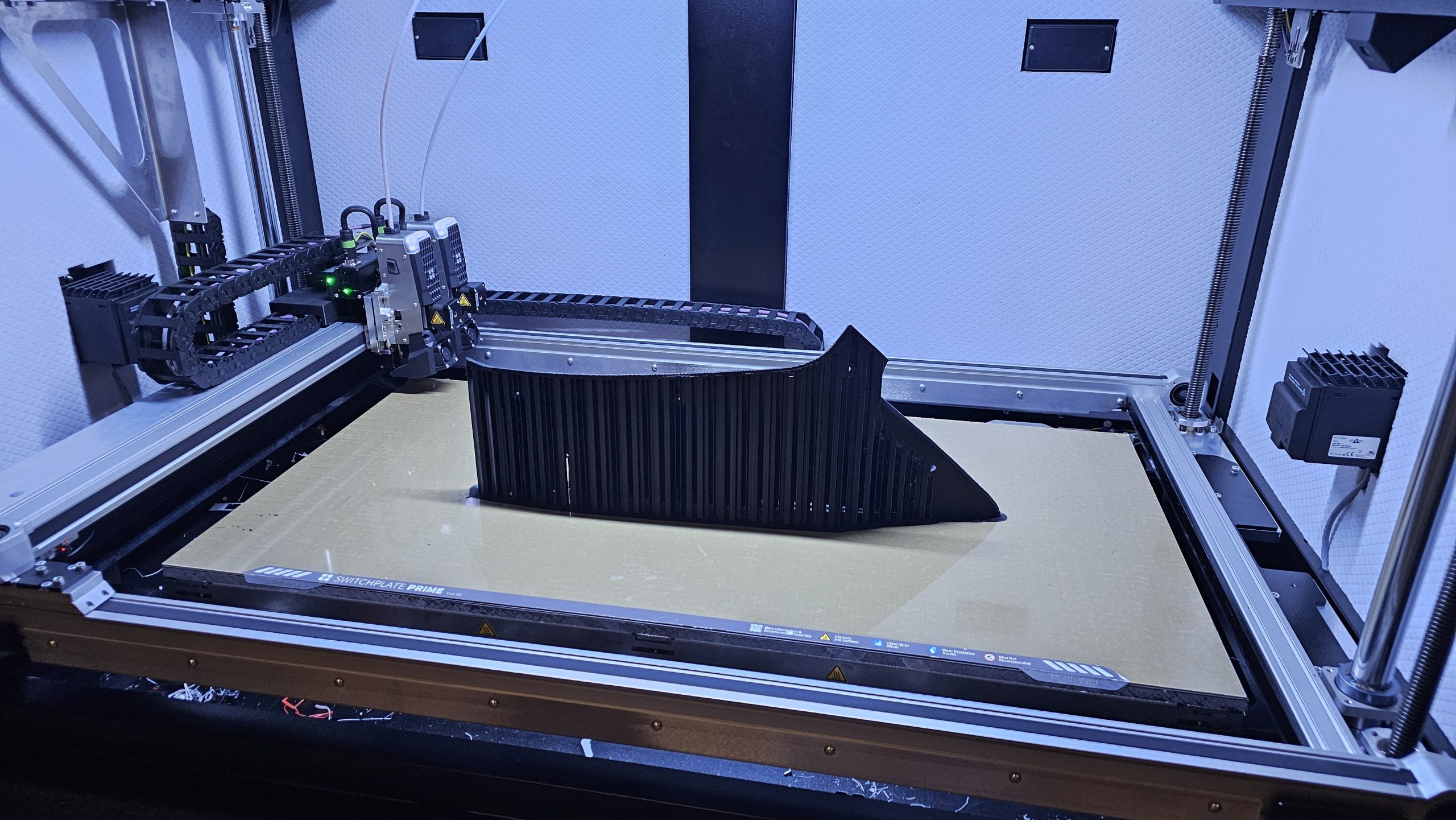

3D Printed in full-scale on the VIIO250 !

NEOMETRIX SOLUTION

The existing parts were carefully prepped using masking tape to hold the disintegrating originals together to the point where they can be 3D scanned. Parts were scanned with the HandyScan Black+ Elite and data exported as an STL file.

“Exceeded expectations on these rear interior pilar covers for my 1981 Toyota Tercel. As you can tell from the photos there wasn’t much to work with and these guys at NeoMetrix Technologies really came through! The fit was incredible for parts that are nearly impossible to find. Thanks again!” – Steve F.

NEOMETRIX ADVANTAGE

The NeoMetrix process provide quick and accurate data on the existing part, as well as the ability to compensate for missing geometry and facilitate design changes in order to 3D print perfectly fitting replacement parts.