Rifle Stock Conversion

3D Scanning & Reverse Engineering Firearm ComponentsAuthor: Kenny Hart – Senior Sales Engineer

Shooting enjoyment is greatly enhanced by a well-fitting, well-designed stock. Unfortunately, the firearms industry at large is lagging, especially in the hunting market. Most stocks sold today are the same swept-back grip design of a century ago with a very low comb (the area where a shooter rests their cheek) and recoil pad, both outdated carry-over geometry from a time when scopes were uncommon, and every rifle stock was made of wood that could more easily break at weak points.

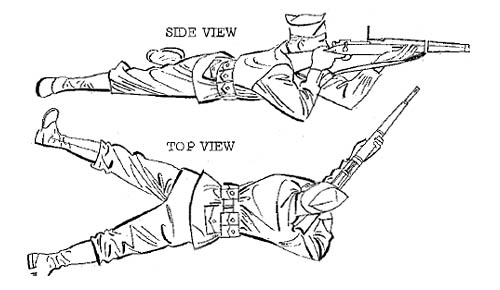

The traditional rifle equipped with iron sights requires a shooter’s face to be low enough to essentially look down the top of the barrel. This necessitates that the buttstock to be lower than the barrel, turning the gun into a moment arm that will pivot in the vertical plane about the shoulder during recoil, which if not controlled properly, will send the bullet above the intended point of impact.

Figure 1: Traditional rifle stock geometry. Note how the low stock comb designed for proper use of iron sights compromises optimal view through the scope, even when mounted as close to the receiver as possible. The swept grip and a recoil pad positioned below the bore axis also detract from maximum shooting forgiveness.

Figure 1: Traditional Rifle Stock Geometry

Figure 2: Traditional Bladed Shooting Style

THE PROBLEM: Current Rifle Geometry is Old Technology

For many shooters, especially youth or small statured individuals, most grip designs place your hand too far back from the trigger, making it difficult or downright impossible to maintain a proper hold on the gun and pull the trigger.

Swept grips keep the weakest part of the traditional wooden stock relatively parallel with the grain to minimize breaking. Unfortunately, this forces your hand into an unnatural position when shooting in a manner that most effectively controls recoil: which is perpendicular to your shoulders. Instead, rifles were traditionally shot in a “bladed” position across the body, which allows the rifle to pivot externally about your shoulder during recoil, again reducing shot-to-shot consistency.

Modern optics and materials have done away with such necessities, and the need for iron sights altogether (today it is hard to find a rifle that still includes them). Injection-molded plastics and fiber layups do not carry the same risk of longitudinal breaks across a grain structure in the grip area that would render your grandfather’s rifle completely useless.

Figure 3: Traditional Bladed Shooting Style

Current Market Options

In this transitional period, a few premium rifles with more desirable stock geometry can be found, but most blue-collar rifle companies (and plenty of expensive ones too!) refuse to innovate and offer such options. This is because it is easier and cheaper to continue selling familiar products to the customer than to educate them as to why moving forward is better.

A small number of aftermarket premium stock manufacturers are beginning to take notice, and as of now, there are about as many models between them as you have fingers on one hand. These stocks are of excellent quality and are handmade one at a time, and therefore have the backorder timeline to reflect as much.

Figure 4: Modern Rifle Stock Designs (top to bottom – Peak 44 Bastion, Stocky’s Ultra Carbon Hunter VG, Manners MCS-EH1, McMillan Game Warden LR-TG, Unknown Munitions Rokstok)

NEOMETRIX SOLUTION

With her first upcoming hunting season, my seven-year-old daughter needed a rifle that she could use efficiently. We had a custom stock on order for my hunting rifle but was informed that my spot on the wait list would surpass our fall whitetail trip. I needed a solution quickly and came up with a workflow using the HandySCAN Black+ Elite along with Geomagic Design X, and a couple of items that can be repeated for additional rifles.

I began by listing the design criteria for the stock:

- A vertical grip to keep the shooting hand in its most relaxed and natural position

- A trigger reach (distance between the front of the grip and the bend in the trigger) of 1.7” to replicate a class-leading stock design, which allows optimal finger placement on the trigger while maintaining grip for large samples of shooters

- An elevated and negative comb (rear of the stock is higher than the front) to properly align the eye with the scope and allow the recoil to pull the stock away from the shooter’s face instead of directly into their cheekbone

- An elevated recoil pad that is perpendicular to the bore of the rifle, to place the recoil impulse more in line with her shoulder

- A shortened, but adjustable length-of-pull (distance from the end of the stock that sits against your shoulder to the trigger face) to grow with a smaller-statured shooter

First to address the grip issue: Tikka T3X rifles ship with the ability to swap a swept grip with a vertical option that is mostly good. But like most grips, it is too far to the rear for anyone with small-to-medium hands to reach the trigger or get an optimal perpendicular pull with their index finger.

Figure 5: OEM Scanned Grip vs New Design

Figure 6: Internal Geometry of Grip

HandySCAN Black+ Elite

Figure 7: Final 3D-Printed Grip Installed

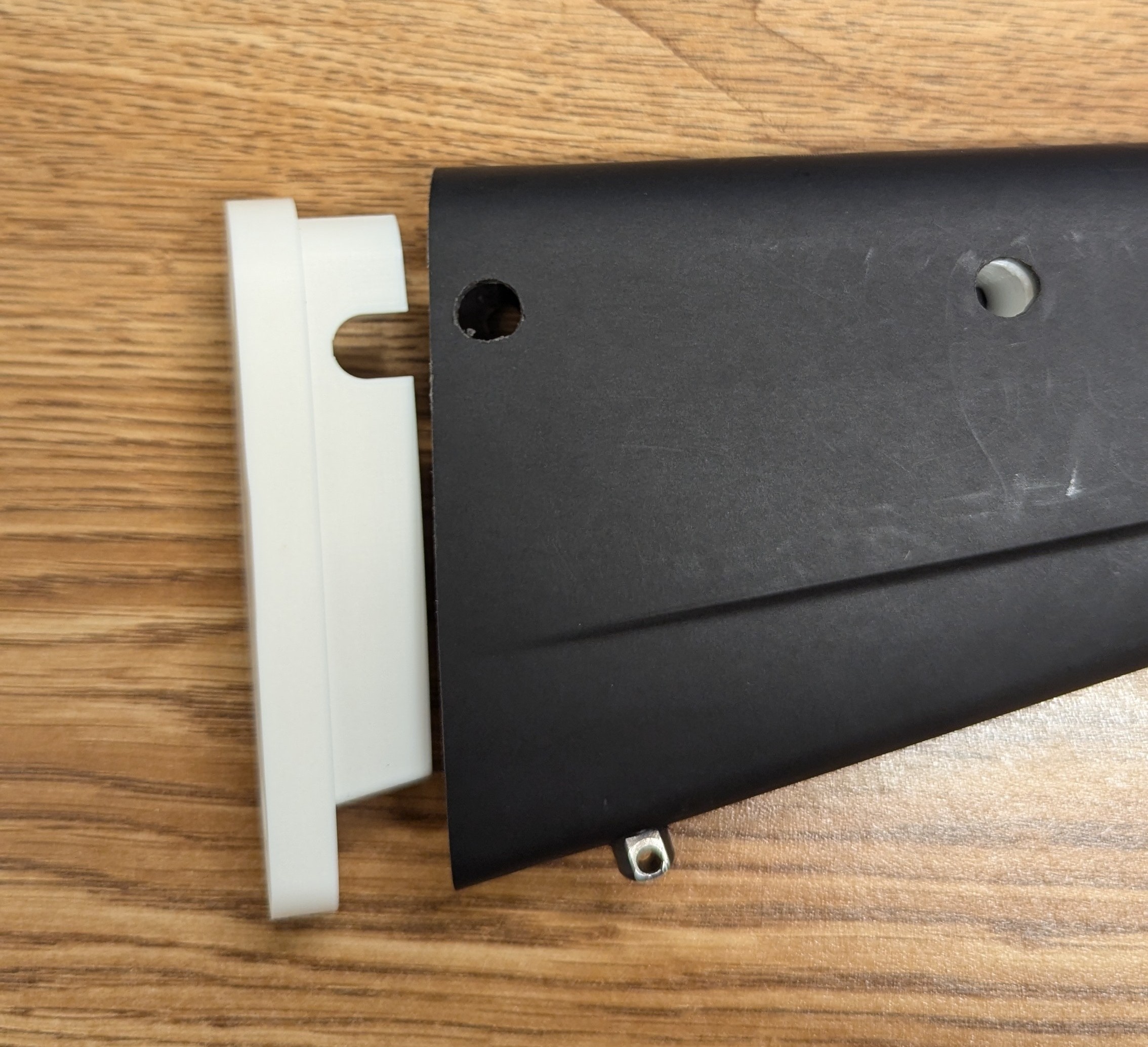

Tackling the rear of the stock properly required that the recoil pad and cheek riser installation be done simultaneously. A Kydex cheek piece from Mountain Tactical was used to adjust the actual comb height and angle, which slips over the top of the stock and attaches with crossbolts through holes drilled into the sides. After deciding on an overall length of pull of 12.9”, the rear of the buttstock was cut perpendicular to the bore for the planned spacer mount. Experimentation with the Kydex cheek riser position yielded the proper mounting bolt locations, which were then drilled and installed.

Figure 8: Planned Position of Recoil Pad and Cheek Riser

At this point, the hollow plastic nature of the stock presented an issue: as the cheek rest bolts were tightened, the sides of the stock collapsed inward before achieving the required tension to hold it in place. To ensure the stock kept its original shape, a cylindrical pillar brace was designed for the front cross bolt. The rear bolt support would be designed into the spacer itself.

A forward extension from the recoil pad spacer would sit on the existing stock comb to prevent the cheek rest from collapsing under a drop or heavy pressure.

The extension shape matches the exact underside profile, providing a functional and aesthetic benefit, preventing anything from becoming lodged underneath the cheek piece and filling the void.

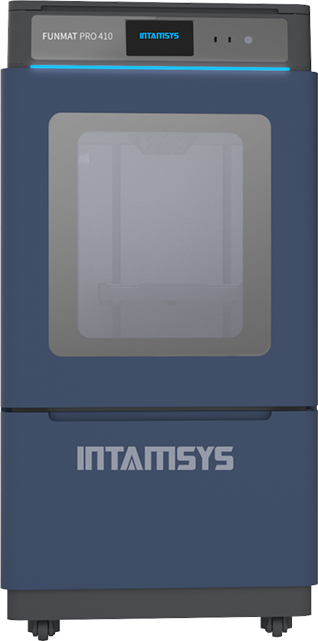

For this, a rear temporary spacer was created with a short insert area that would fit down into the rear stock opening, just past and around the rear screw to hold everything in place when assembled. The pillar and spacer were then 3D printed on an INTAMSYS FUNMAT PRO 410 and assembled to 3D-scanned again for the exact shape of the underside of the cheek piece.

The final spacer adapter was modeled to blend with the existing buttstock geometry and provide the target length of pull with a 0.8” recoil pad installed. The recoil pad mounting surface was raised nearly an inch, would permanently attach to the stock with the factory wood screws, and have the ability to both increase and decrease the length of pull by swapping recoil pads of varying thicknesses or adding additional spacers.

To prevent the threads of the spacer from ever wearing out over repeated swaps and adjustments, threaded brass inserts to accept machine screws were designed and added into the spacer, which secured a Pachmayr “Old English” recoil pad. Finally, a forward extension was incorporated to fully support the rear of the cheek rest.

INTAMSYS FUNMAT PRO 410

Figure 9: Temporary Spacer and Front Pillar to Support Stock Geometry

NEOMETRIX ADVANTAGE

Once the final recoil pad spacer was 3D printed on the same 410 machine, this time out of Peek-Carbon Fiber (PEEK-CF) material for its superior environmental and temperature resistance, the entire rifle was assembled. The new design allowed my daughters to get behind the gun more easily and shoot consistently, without lifting their heads off the stock to see through the scope or letting go of the grip to put their finger on the trigger. After confirming the success of the newly optimized geometry, a second stock was altered in the same manner, for when the time comes to purchase my younger daughter her own Tikka rifle.

This is the stock design that the firearms industry needs to adopt, as it allows a rifle to be fit to anyone, while retaining a pleasing, somewhat classic look. Until that time, my daughters have a two-of-a-kind design to enjoy!

Figure 10: Recoil Pad Spacer

Figure 11: Final Stock Assembly

Author: Kenny Hart – Senior Sales Engineer