Developing and manufacturing tools and prototypes can be an uphill task.

In a highly competitive manufacturing environment, the right fabrication method may decide whether a pipeline project will be launched or not. Traditional manufacturing processes like injection molding, thermoforming, or casting often present challenges, including:

-

High Upfront Costs: Financing prototypes, molds, or patterns can be expensive.

-

Long Lead Times: It can take weeks or months to receive parts from providers.

-

Development Roadblocks: Delays in the development process can create a competitive disadvantage.

What is Rapid Production Tooling?

Rapid production tooling is a technique to manufacture tools and prototypes using 3D printing technology, such as fused filament fabrication (FFF). Unlike rapid prototyping—which focuses on iterating parts—rapid tooling is about producing tools like jigs, fixtures, molds, patterns, or dies for traditional manufacturing processes. This method bridges the gap between prototyping and full-scale production of end-use parts.

FREE EBOOK DOWNLOAD

Learn how industrial leaders around the world are leveraging large-format additive manufacturing to eliminate up to 94% of lead times by cutting out third parties and taking control of their supply

chains.

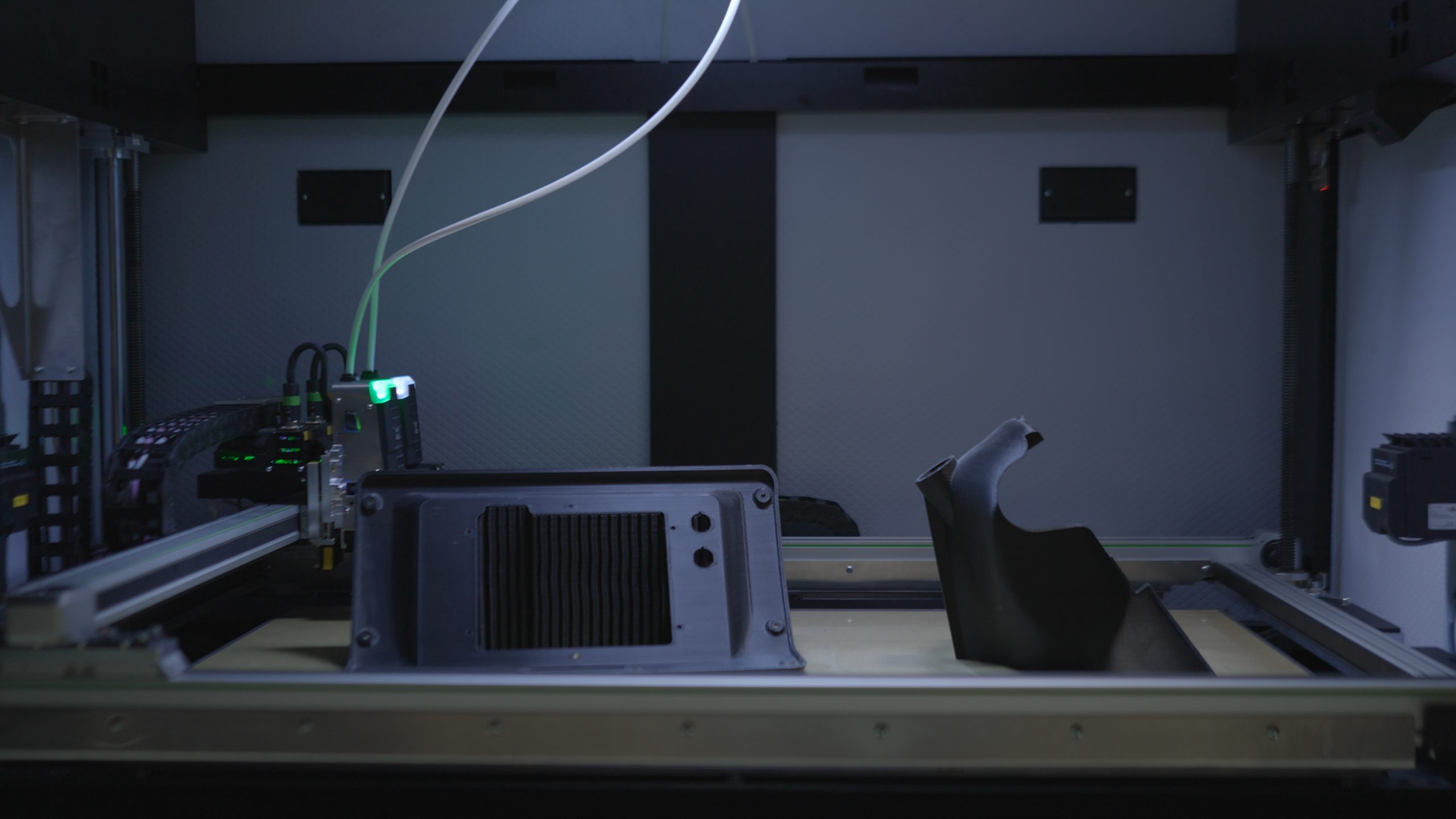

Ford developed the sensor fixture shown below to assist with the manual placement of door sensors—the ones that trigger dashboard alerts when a door isn’t fully closed.

While a smaller, handheld fixture could have been an option, using it would require repeated alignments, increasing the chances of human error and taking up valuable time. Instead, Ford opted for a large-format fixture that matches the entire door frame precisely. This one-to-one fit minimizes errors and significantly speeds up the sensor placement process.

The Benefits of Using 3D Printing for Production Tooling

- Mold for Casting & Injection Molding

- Jigs & Fixtures

- Prototyping Tools & End-use Parts

- Thermoforming Tools

USAGE: Molds bring materials into desired forms e.g., metals, plastics, rubber.

WHY CHOOSE 3D PRINTING?

Allows complex molds to be produced quickly at lower cost, useful for low-volume production runs or prototype parts. Materials e.g., photopolymers, metal-filled resins.

USAGE: Tools to hold, support, or guide a workpiece during manufacturing, assembly, or inspection processes.

WHY CHOOSE 3D PRINTING?

Allows custom jigs and fixtures with complex geometries tailored to the shape of parts being worked on to speed up the production process, reduce errors, and improve accuracy. Create lightweight and ergonomic tooling, particularly useful for handheld devices.

USAGE: Used to test and validate designs before going into full-scale production.

WHY CHOOSE 3D PRINTING?

Allows manufacturers to build functional prototypes or end-use parts quickly for testing, particularly important in industries like aerospace, automotive, and medical devices, where design iterations need to be evaluated before full production begins.

USAGE: Used in processes where a material is heated and formed into a specific shape by pressing it against a mold.

WHY CHOOSE 3D PRINTING?

Allows rapid production of molds with complex surface details that can reduce the need for post-processing and enhance the final product quality. Ideal for low-volume runs or prototypes before moving to traditional tooling for high-volume production.

Rapid tooling with BigRep 3D printers revolutionizes supply chains by dramatically reducing manufacturing and turnaround times. Instead of waiting weeks or months for traditional tooling, BigRep’s large-format 3D printing technology enables businesses to produce custom jigs, fixtures, molds, and end-use parts in-house within days. This speed not only minimizes production delays but also enhances supply chain flexibility by allowing manufacturers to iterate designs quickly, respond to market demands faster, and maintain lower inventory levels—all contributing to streamlined operations and improved efficiency.

Speed

In-house production reduces logistics and accelerates manufacturing, delivering parts in days instead of weeks.

Cost-Effectiveness

Lower initial costs compared to CNC machining, especially for small quantities and complex geometries.

High Quality

Advanced 3D printers offer precision and consistency with minimal post-processing.

Flexibility

Easily produce modified duplications and iterate designs quickly.

Accessibility

Having an in-house 3D printer eliminates long wait times from outsourced manufacturing.

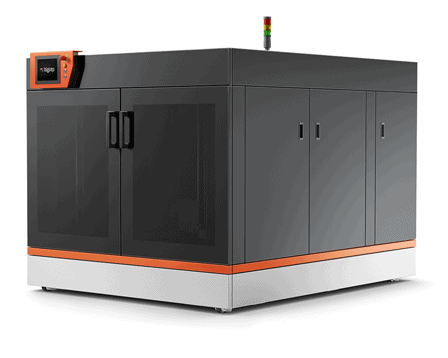

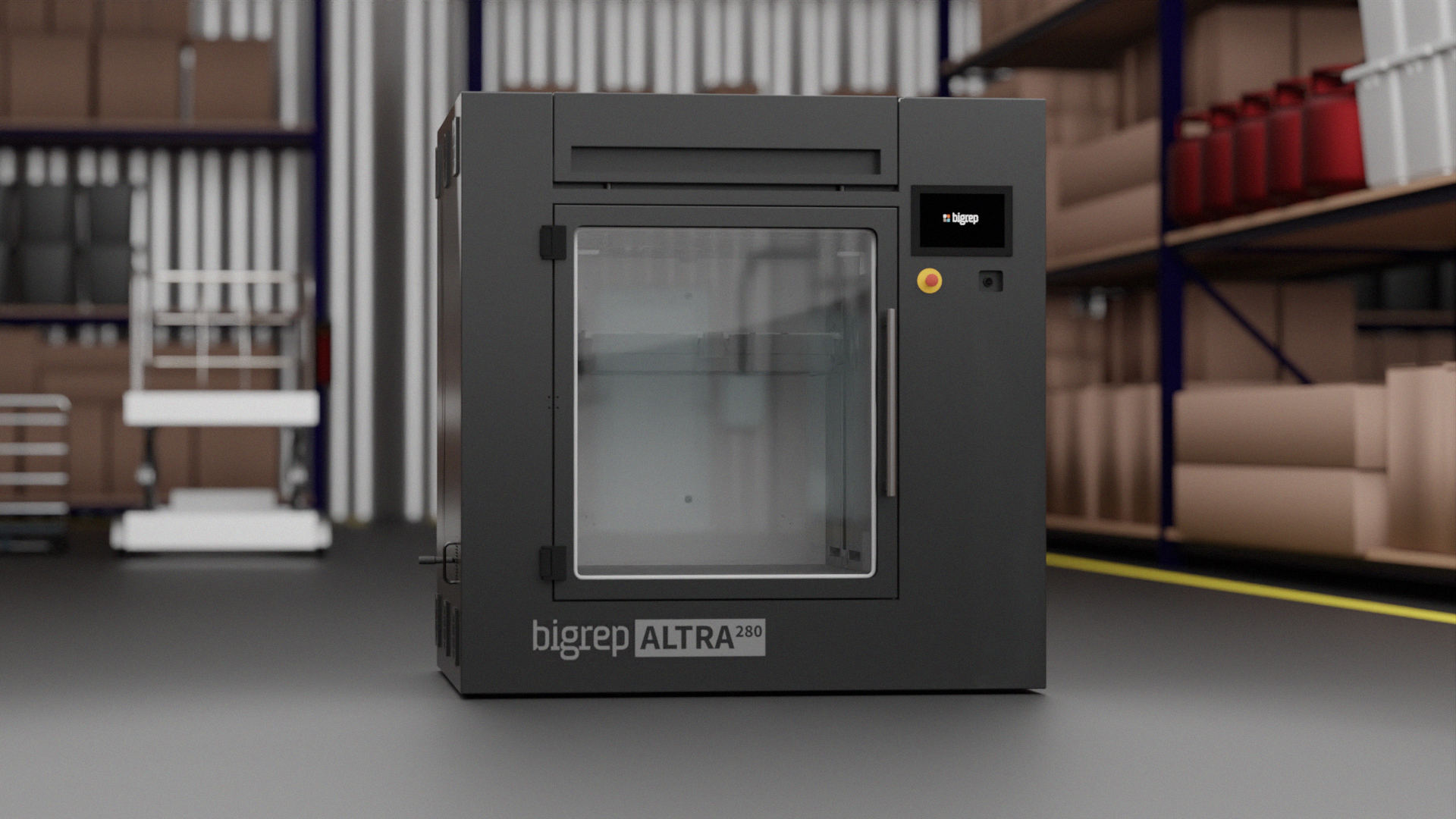

BigRep 3D Printers: A Solution for Rapid Tooling

BigRep 3D printers offer an impactful solution in the rapid tooling industry. Their large-format industrial printers enable manufacturers to produce high-quality tools, jigs, and fixtures at a fraction of the time and cost of traditional methods. With advanced materials such as HiTemp CF, BigRep provides robust and durable tooling solutions for demanding applications.

Want to Learn More About 3D Printing?

Original Source: https://bigrep.com/posts/rapid-tooling-with-3d-printers-a-step-by-step-guide/?utm_source=newsletter&utm_medium=email&utm_campaign=february+2025&vgo_ee=PE5Zoxnz63hMxrvmgtvLdMk%2FlZ1DWcd%2BKkFpCSEd8NIXevaJ8A%3D%3D%3AjPqYyWkFx8VZnX6RvFwvf7j%2BDwu7Zgds