BigRep 3D printers are a game-changer for businesses seeking innovation and efficiency.

At NeoMetrix Technologies, we understand the growing need for flexibility and innovation in 3D printing. As industries push the boundaries of what’s possible, the question often arises: Which is better for your business, an open or closed material system?

Embracing the Open 3D Printing System

While closed systems offer consistent, predictable results by limiting you to proprietary materials and predefined print profiles, open material systems deliver far greater flexibility. Open systems allow manufacturers to explore a wider variety of filaments, create custom print profiles, and adapt to the ever-evolving landscape of 3D printing materials.

Whether you’re printing with low-temperature PLA or high-performance PEEK, the right material for your project depends on your specific application:

- PLA: Biodegradable, easy to use, and ideal for prototyping.

- PETG: Durable and impact-resistant, perfect for functional parts.

- ABS & ASA: High-strength materials suitable for demanding environments and outdoor applications.

- Polycarbonate: Tough and transparent for high-impact and clarity needs.

- PEEK: The ultimate high-temperature plastic, used in aerospace and medical industries for its mechanical and chemical resistance.

Why Choose Open Material Systems?

The beauty of an open material system is that it puts the power in your hands. You can experiment with different materials, customize settings for the perfect print, and work with both proprietary and third-party filaments. For industries like aerospace, medical, and automotive, where innovation is essential, this flexibility opens up new possibilities.

For instance, as materials like conductive polymers and carbon fiber composites enter the market, manufacturers with open systems are better positioned to capitalize on these advancements, driving efficiency and improving performance.

Exploring Material Options: From Low to High-Temperature Plastics

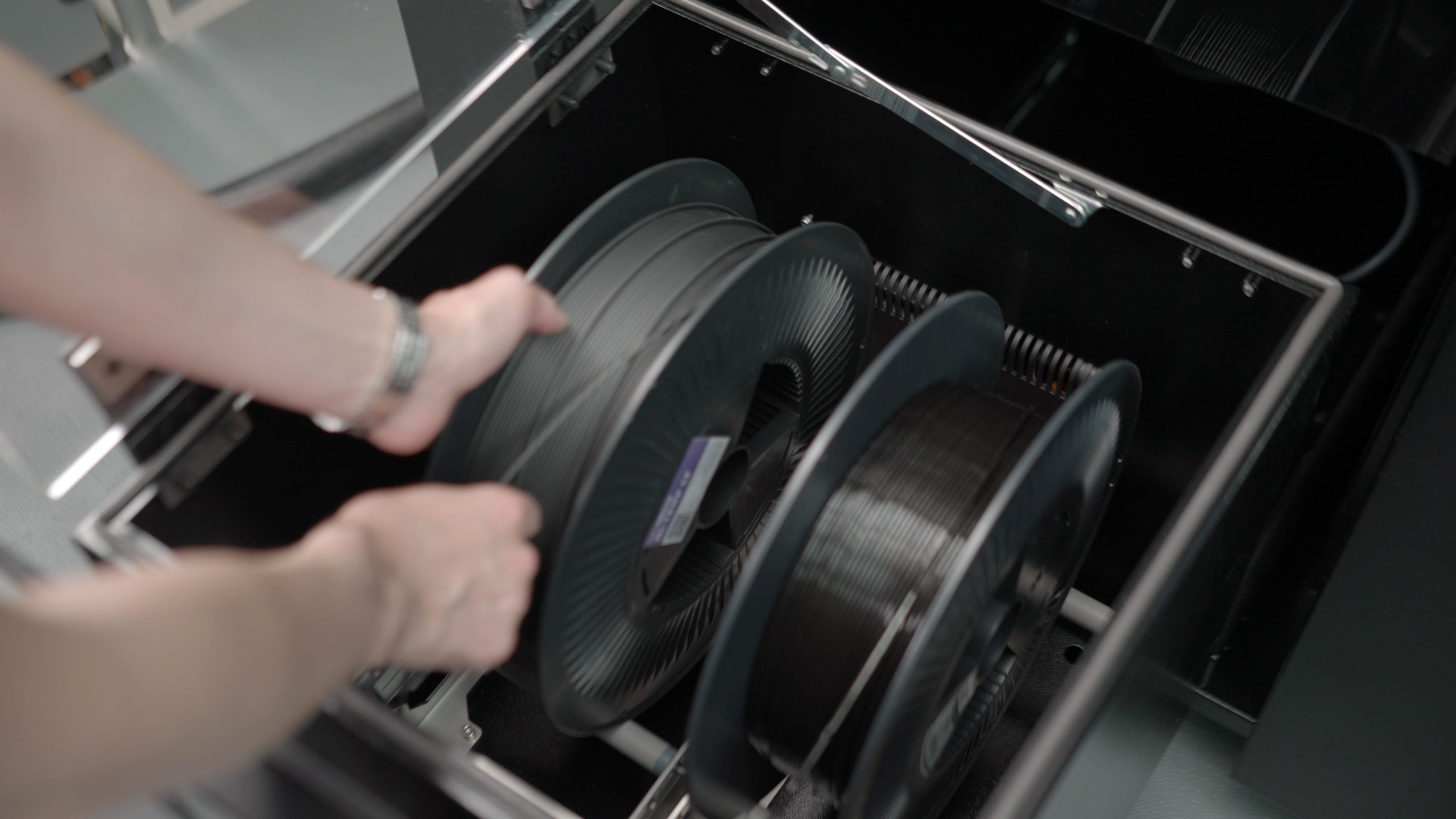

BigRep’s large-format 3D printers feature open material systems, allowing you to work with a wide range of materials—from affordable, general-use filaments to technical, industrial-grade options. With this system, you have the freedom to push boundaries and explore innovative applications without being locked into a proprietary ecosystem.

Plus, with BigRep BLADE, our slicing software, you can easily create and customize print profiles for any material. This means faster print times, less material waste, and optimized part quality—no matter your level of 3D printing experience.

BigRep Open Material Systems: The Freedom to Innovate

Get Started! – Schedule a 3D Printing Discovery Session

Ready to unleash innovation, optimize workflows, and stay ahead in the competitive landscape with NeoMetrix Technologies? Every top modern business deserves access to the transformative capabilities of 3D printing.

Schedule a FREE 3D Printing Discovery Session to see which solutions and equipment are best to suit your design and production challenges. Also be sure to download our BigRep Smart Decision Blueprint.