In the dynamic world of aerospace manufacturing, staying ahead of the curve is crucial for industry leaders. With cutting-edge technologies reshaping the landscape, 3D printing has emerged as a game-changer, revolutionizing prototyping and on-demand parts production. NeoMetrix Technologies brings you the key to unlock boundless possibilities in aerospace manufacturing through their advanced 3D printers. In this blog, we’ll explore why investing in 3D printers can help aerospace companies solidify their position as industry leaders.

In the dynamic world of aerospace manufacturing, staying ahead of the curve is crucial for industry leaders. With cutting-edge technologies reshaping the landscape, 3D printing has emerged as a game-changer, revolutionizing prototyping and on-demand parts production. NeoMetrix Technologies brings you the key to unlock boundless possibilities in aerospace manufacturing through their advanced 3D printers. In this blog, we’ll explore why investing in 3D printers can help aerospace companies solidify their position as industry leaders.

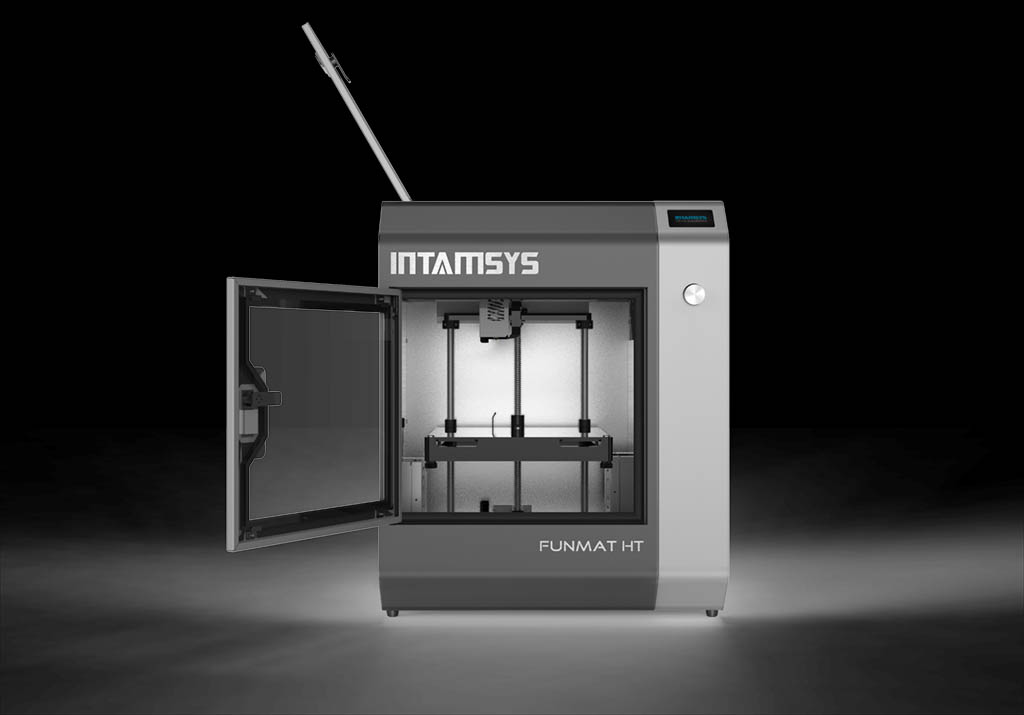

Gone are the days of waiting for weeks to get physical prototypes. 3D printers empower aerospace companies to create intricate and precise prototypes within hours. This rapid prototyping capability enables faster design iterations, expediting the development process and reducing time-to-market.

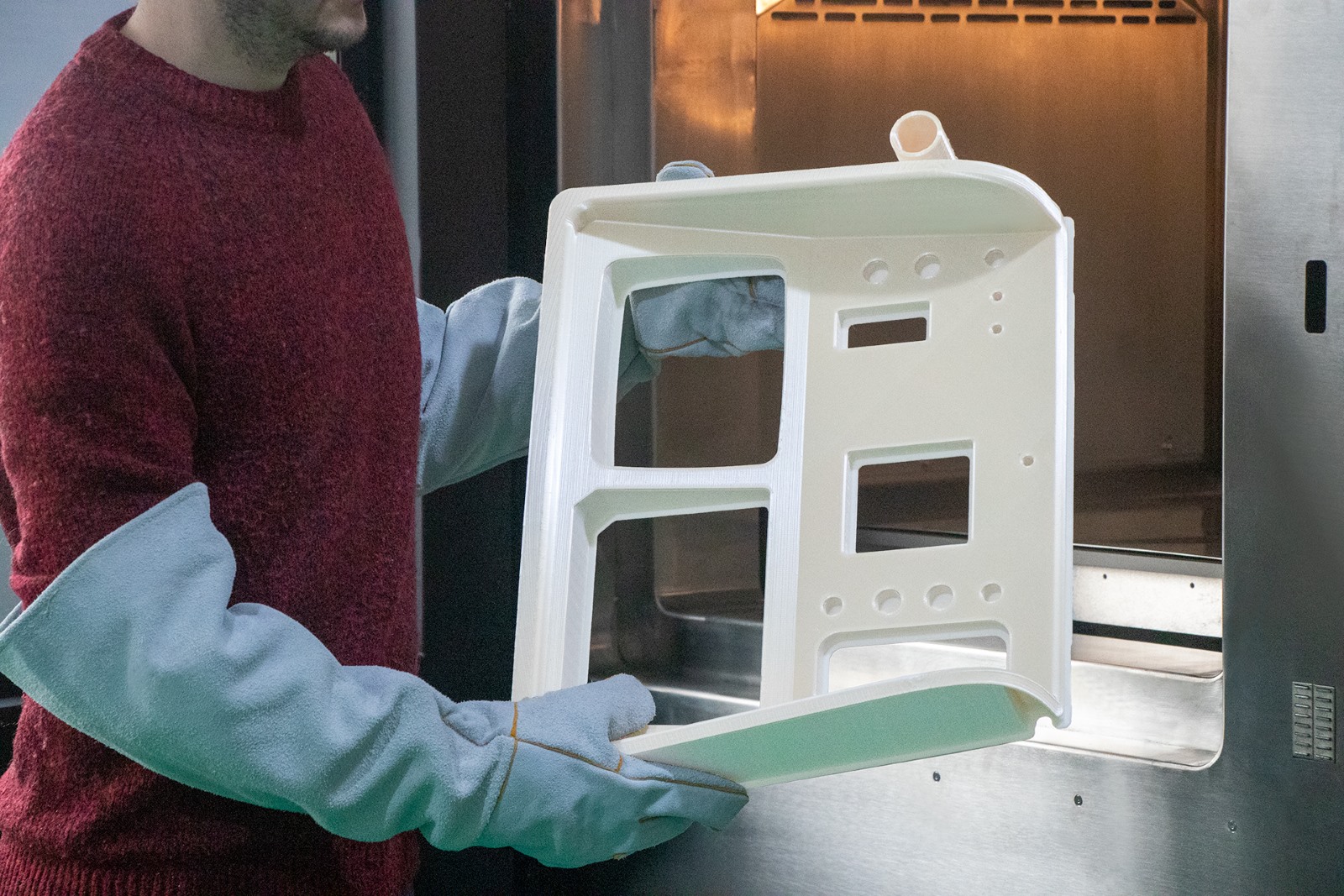

3D Printed Helicopter Blade Cradles

3D Printed Molds for Aerospace Engine Exhaust Covers

On-Demand Parts Production

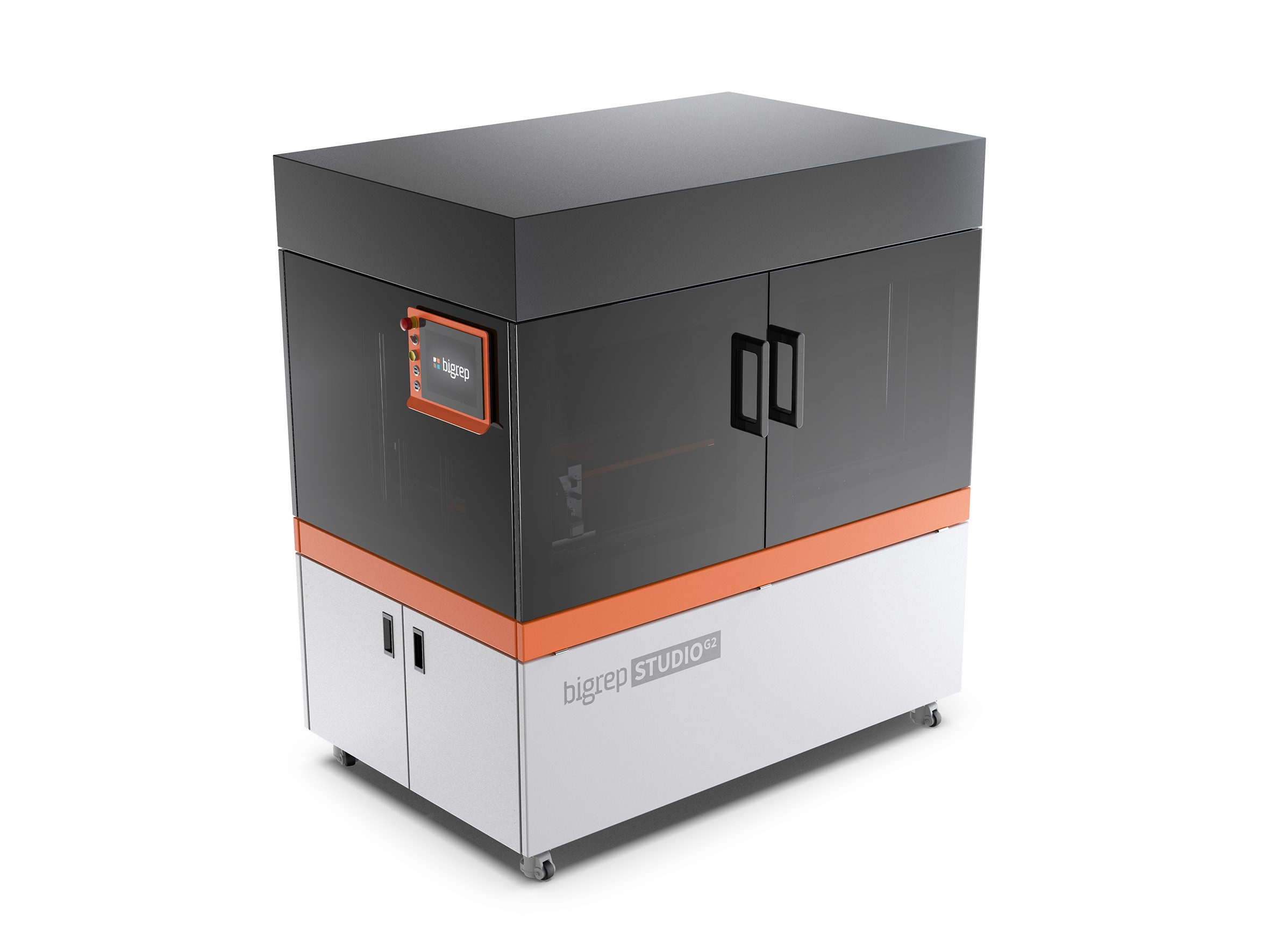

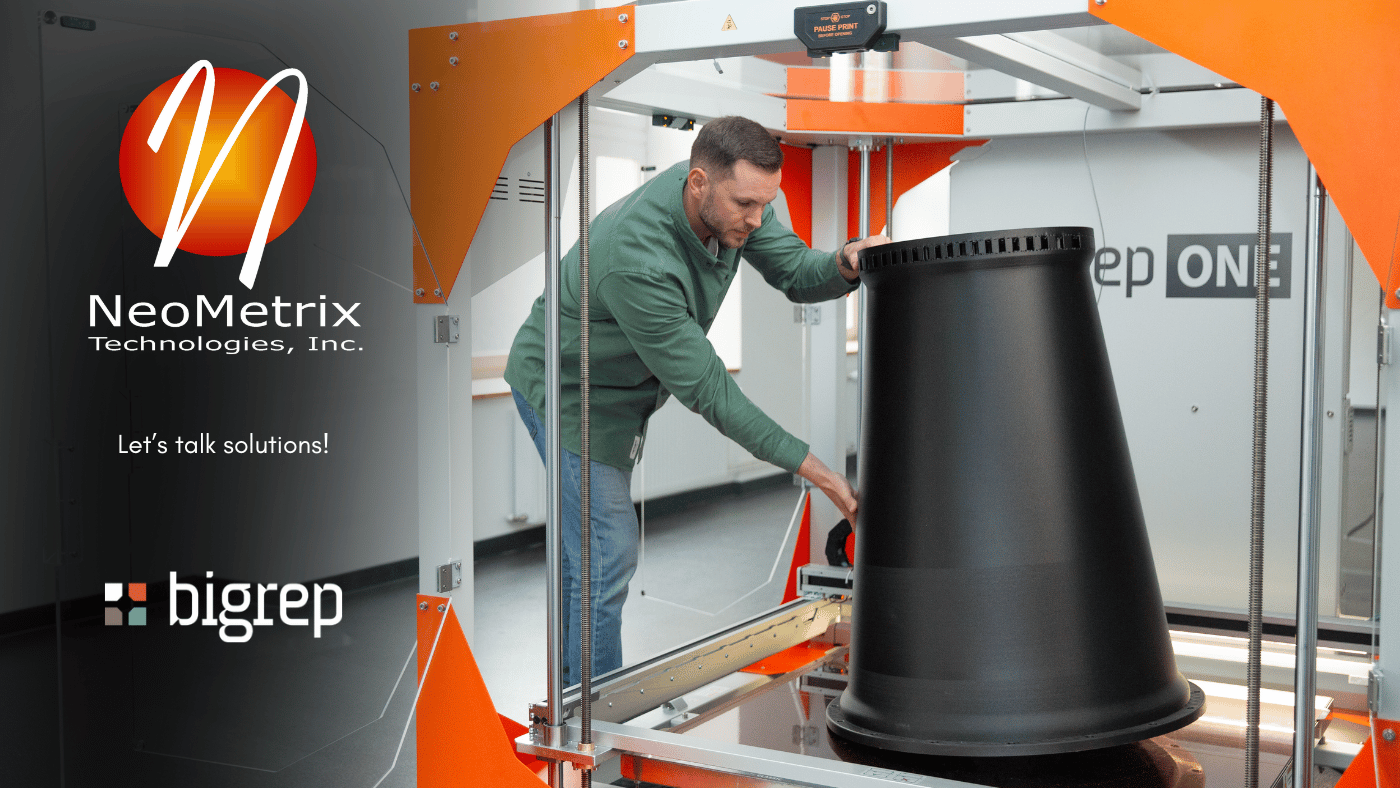

In the highly competitive aerospace industry, agility is key. With NeoMetrix’s 3D printers, aerospace companies can produce end-use parts on demand, eliminating the need for large and costly inventory. Whether it’s a custom component or a hard-to-find spare part, 3D printing ensures immediate access to the required parts, reducing downtime and production delays.

Enhanced Design Flexibility

Aerospace manufacturing demands constant innovation and adaptation. 3D printing allows engineers and designers to explore complex geometries and create lightweight, optimized parts. This design flexibility opens doors to create next-gen aerospace components that push the boundaries of traditional manufacturing techniques.

Cost-Effectiveness and Waste Reduction

Traditional manufacturing processes often generate significant material waste. 3D printing, on the other hand, adds material only where it’s needed, reducing waste and minimizing material costs. This eco-friendly approach aligns with sustainable practices, enhancing the company’s reputation and meeting environmentally conscious standards.

Streamlined Supply Chain Management

By embracing 3D printing, aerospace companies can reduce their reliance on external suppliers and streamline their supply chain. This autonomy over production can result in cost savings and improved control over the manufacturing process, ensuring consistent quality in the final products.

In a fast-paced aerospace industry, being at the forefront of technological advancements is essential to maintain a competitive edge. Investing in 3D printing with NeoMetrix Technologies offers aerospace companies an opportunity to lead the pack, leveraging rapid prototyping, on-demand parts production, design flexibility, cost-effectiveness, and streamlined supply chain management. Embrace the future of aerospace manufacturing with NeoMetrix’s advanced 3D printers and elevate your position as an industry leader. Stay ahead of the curve and unlock a world of endless possibilities!