Improving Development Time and Accuracy with 3D Scanning

Solutions for Automotive Product Development Discover Your 3D Solutions!THE PROBLEM

The aftermarket automotive industry faces many challenges in developing new products for new and existing vehicles. Aftermarket parts are expected to fit as well as OEM parts, but the engineering data is rarely available from the original manufacturer. This means that those work in this industry need to get creative in extracting the information they need to ensure the production of quality parts.

TRADITIONAL METHOD

Old school techniques of using hand tools to measure existing parts can be quite cumbersome. Hand tools are also ineffective at measuring the complex geometry found in current automotive designs. Finally, manually entering all that data into a CAD system to develop 3D models is not only difficult, it is fraught with potential human errors in keying incorrect values. These errors only become evident when the new part is produced, and does not fit as well as intended or required.

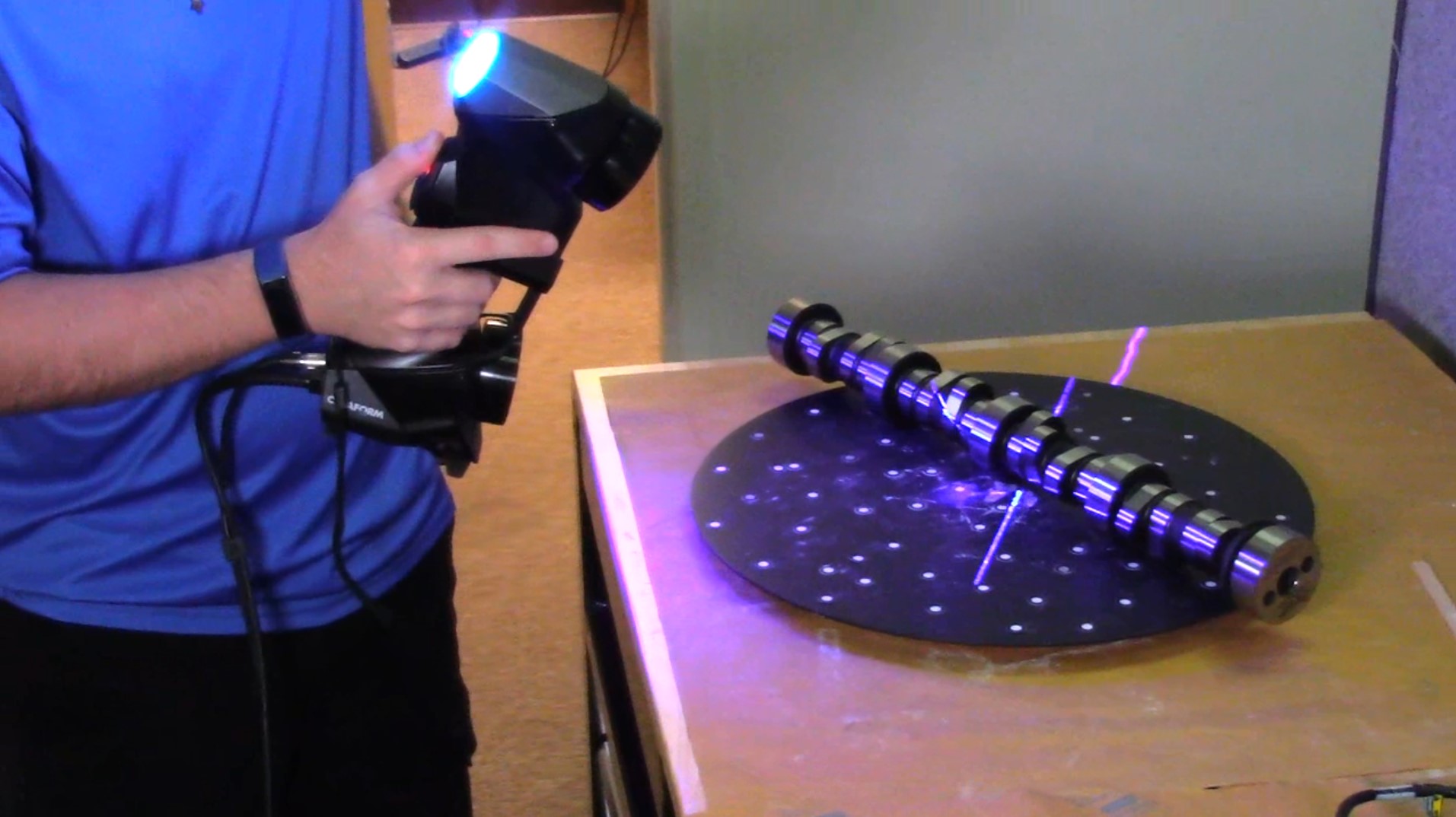

Crankshaft 3D Scan Mesh

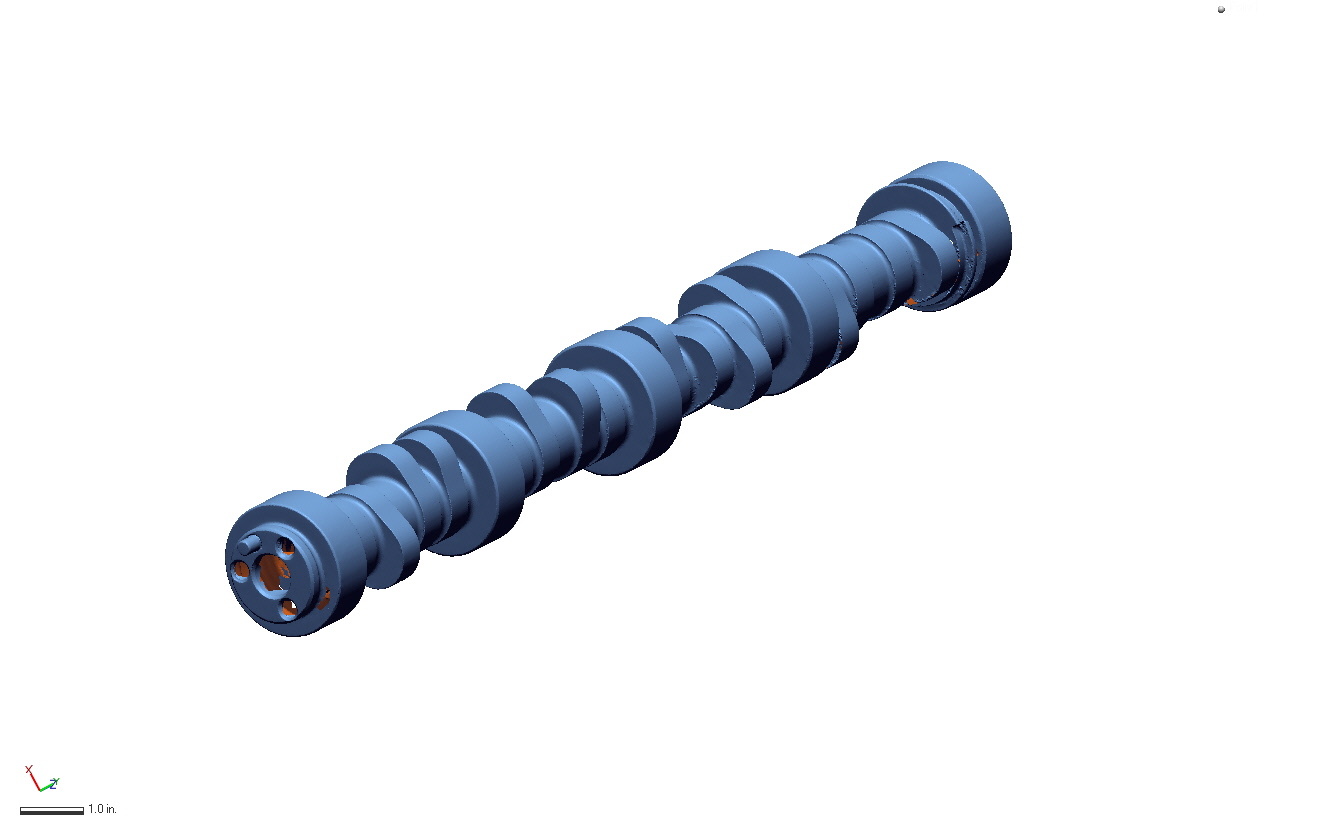

Crankshaft CAD Model

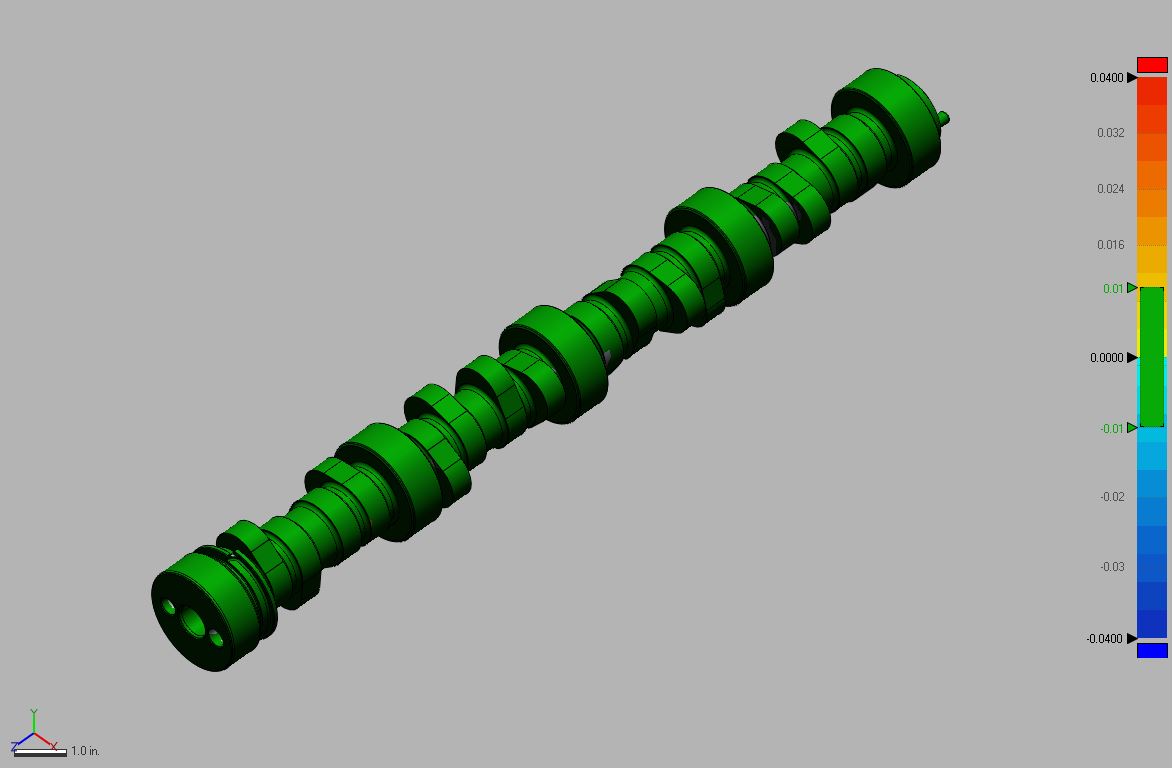

Deviation Map

NEOMETRIX ADVANTAGE

This digital workflow improves development time as well as the accuracy and quality of the final part. Faster development means new products can be brought to market much more quickly resulting in improved revenue streams.