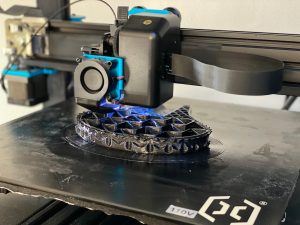

At NeoMetrix we’ve invested in a wide variety of 3D printing technologies in order to meet the demands of our customers. From small high accuracy multi-jet parts to large functional builds, we’ve got you covered directly from our facility here in Florida!

- Engineering-grade and chemical resistant materials to meet the requirements for your parts

- From Small high-resolution and detailed parts, to large-format functional parts

- Thousands of successfully printed parts for clients across various industries and still growing!

Here’s how we can help solve your 3D Printing challenges!

Composites

Technology: FDM/FFF

Max Build: 1000 x 500 x 500 mm (39 x 19 x 19 in)

Materials:

-

ProHT, PLA, HiTemp CF

-

Break Away & Soluble Supports

-

Other materials also available

Thinker from 3D Scan (~17” Tall) – BigRep ProHT

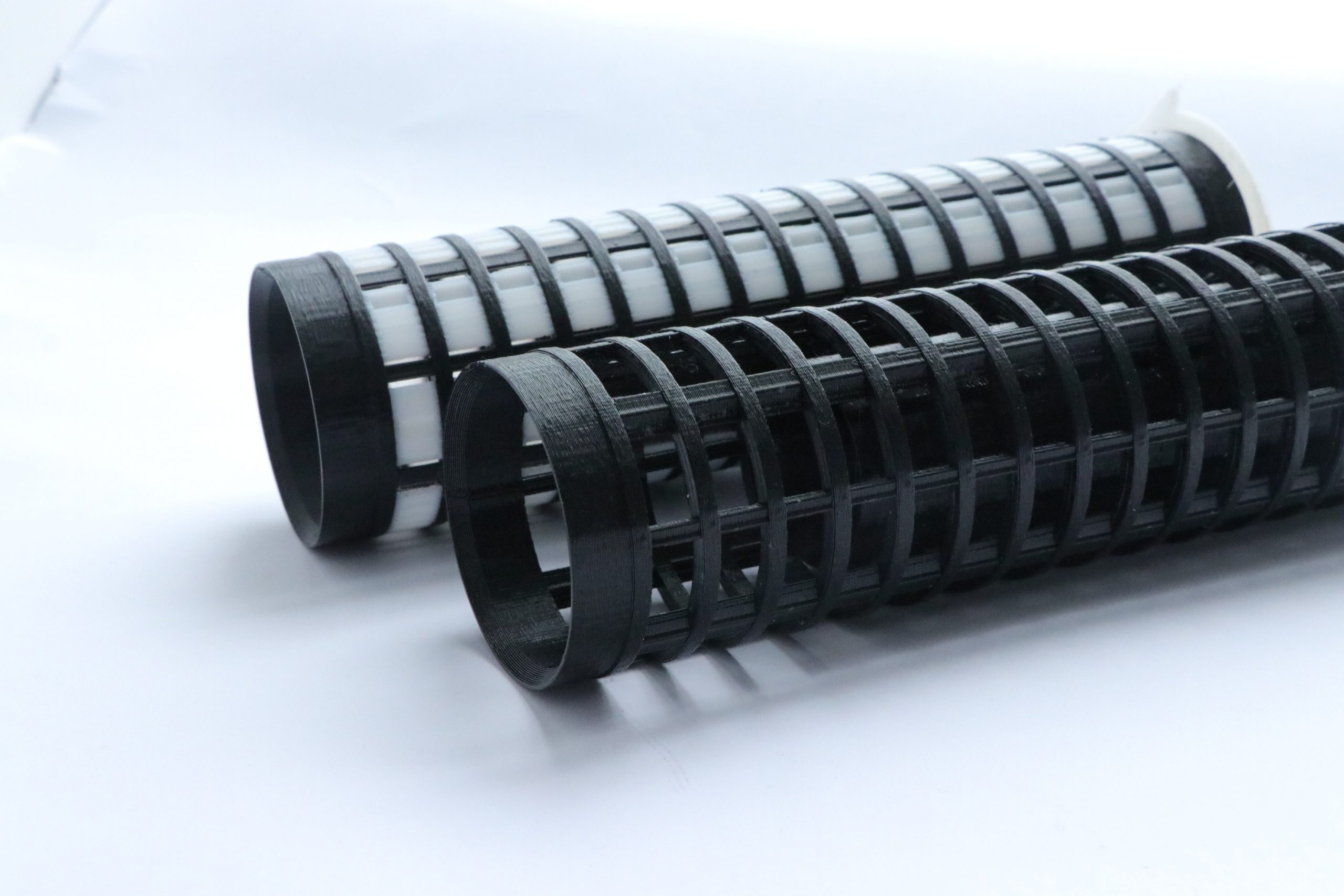

Composites

Technology: FDM/FFF

Max Build: 305 x 305 x 406 mm (12 x 12 x 16 in)

Materials:

-

ABS, PC, PLA, PA6, PA6 CF, Peek, Peek CF

-

Break away & soluble supports

-

Other materials also available

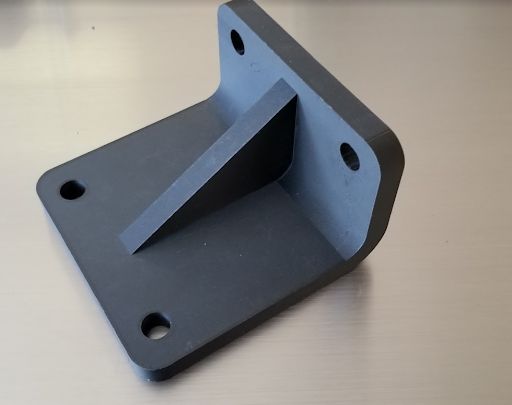

Lightweight Frame- Automotive Parts

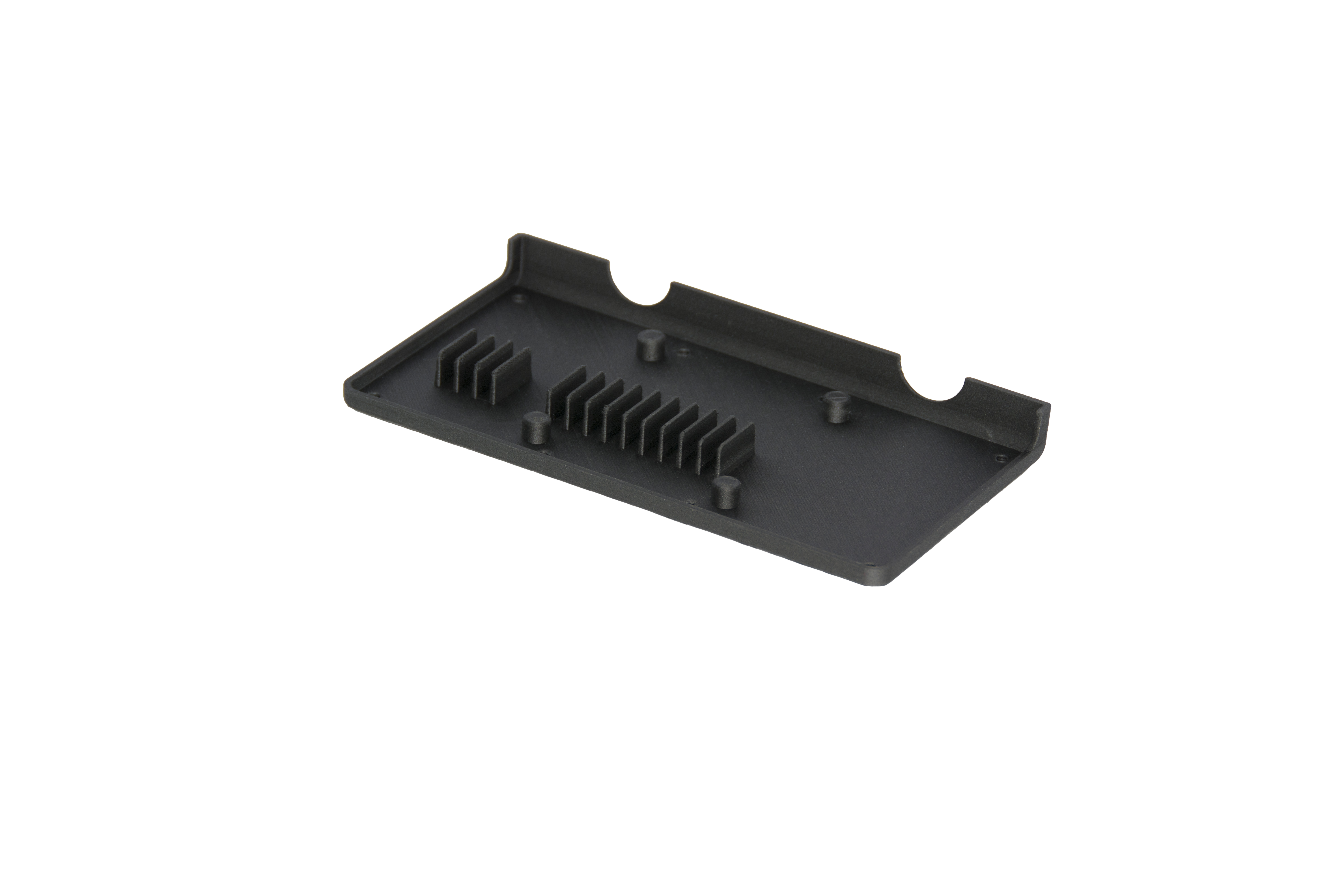

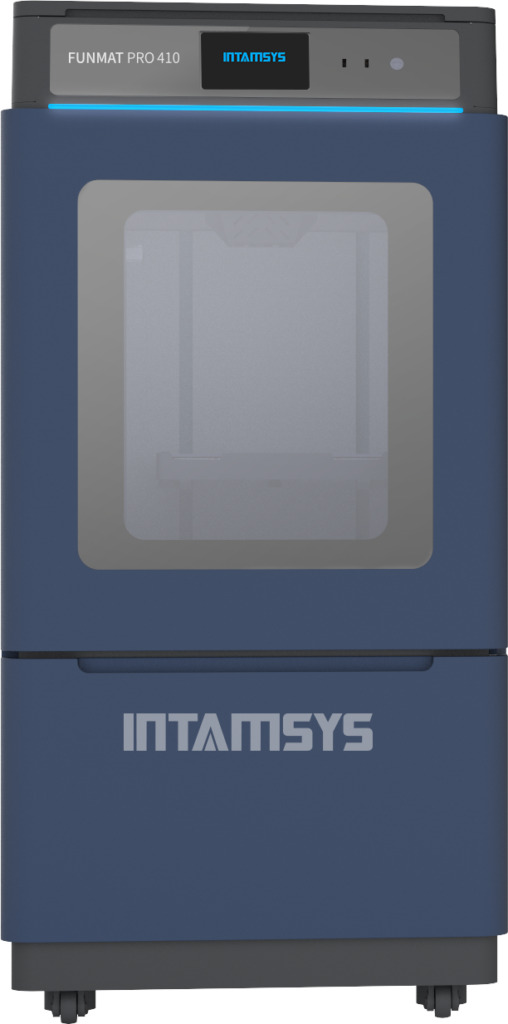

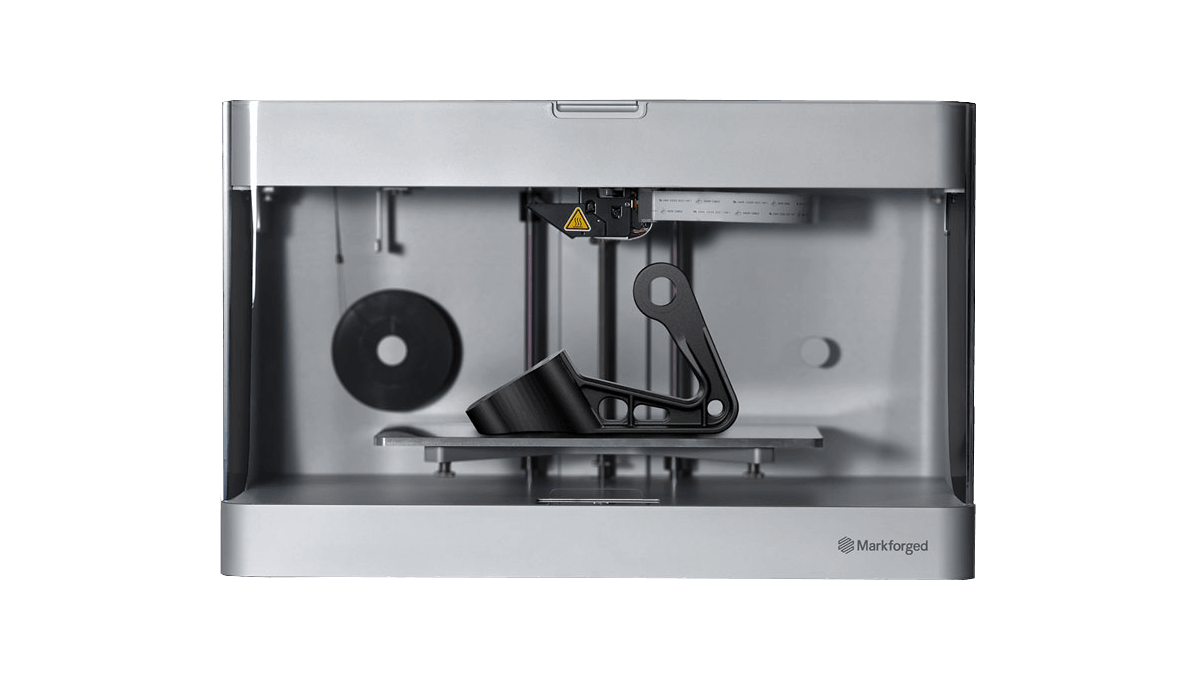

Composites

Technology: FDM/FFF

Max Build: 330 x 270 x 200 mm (13 x 10.6 x 7.9 in)

Materials: Onyx (PA6 CF)

Reinforcing Fiber: Continuous Carbon (0.15 in min. thickness)

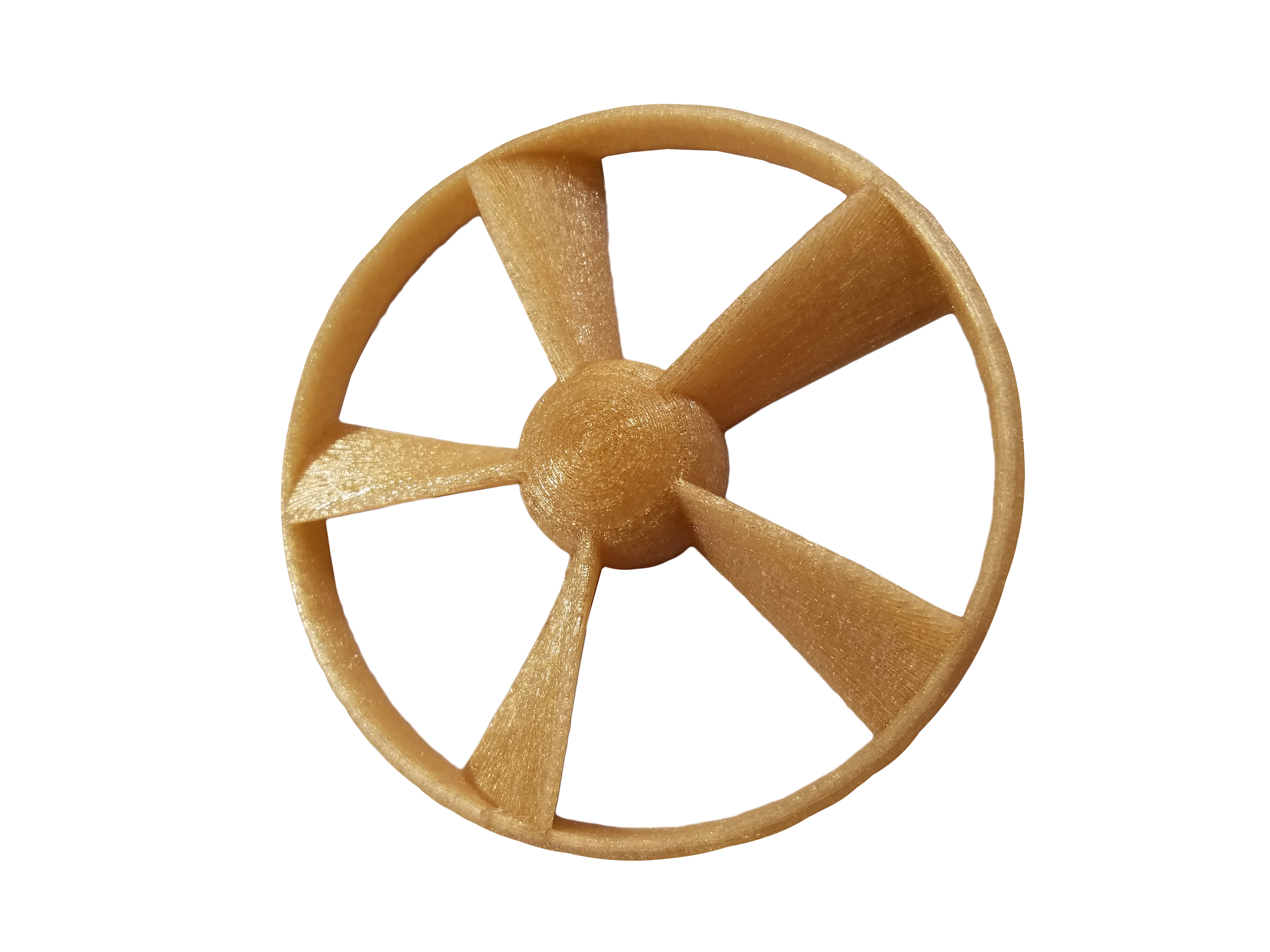

Metal

Technology: FDM/FFF

Max Build: 235 x 65 x 68 mm (9.25 x 2.7 x 2.6 in)

Materials: 17-4 Stainless, & Tool Steel

Impeller (~1” tall) – Markforged Metal X 17-4 Stainless Steel

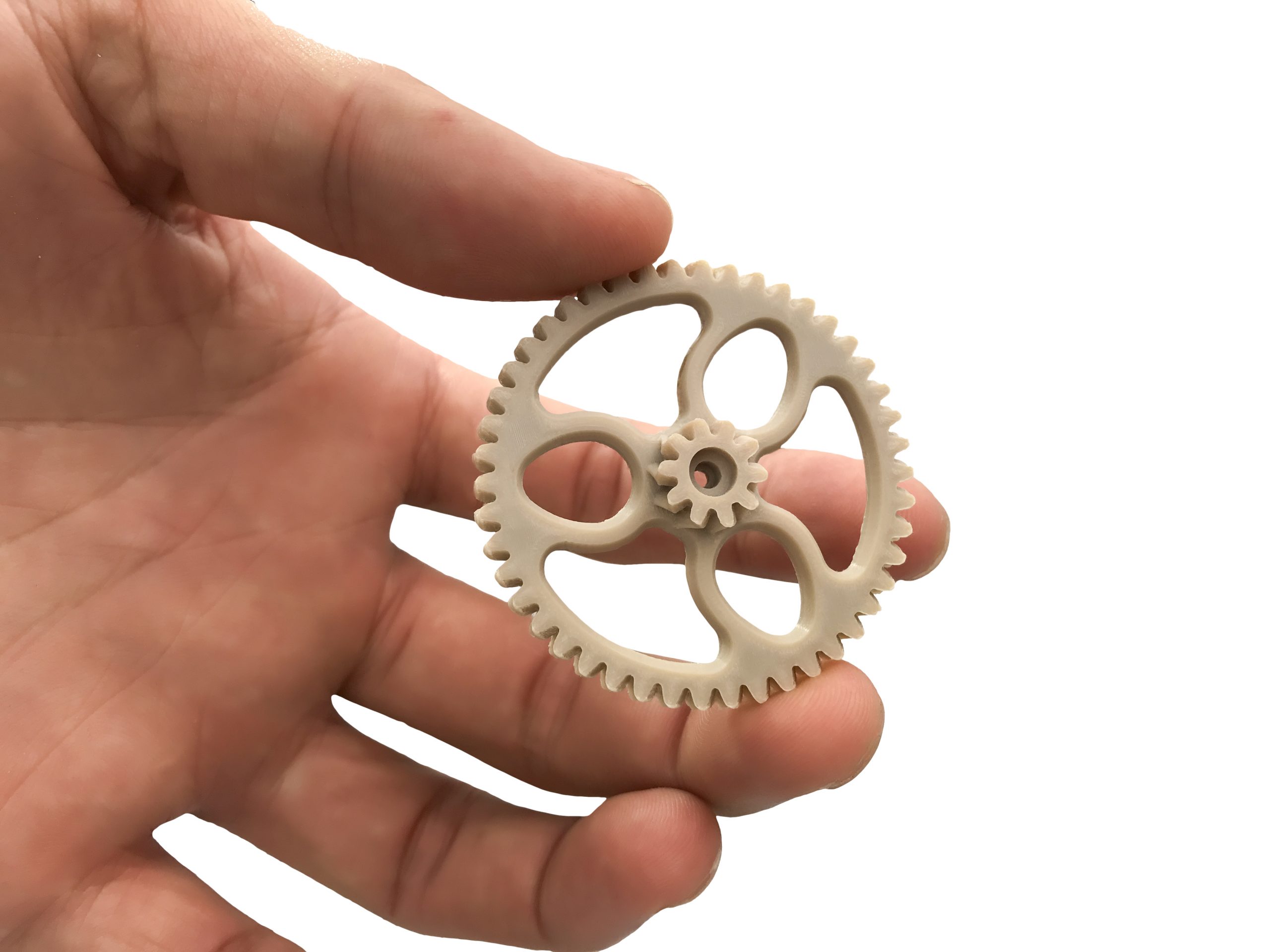

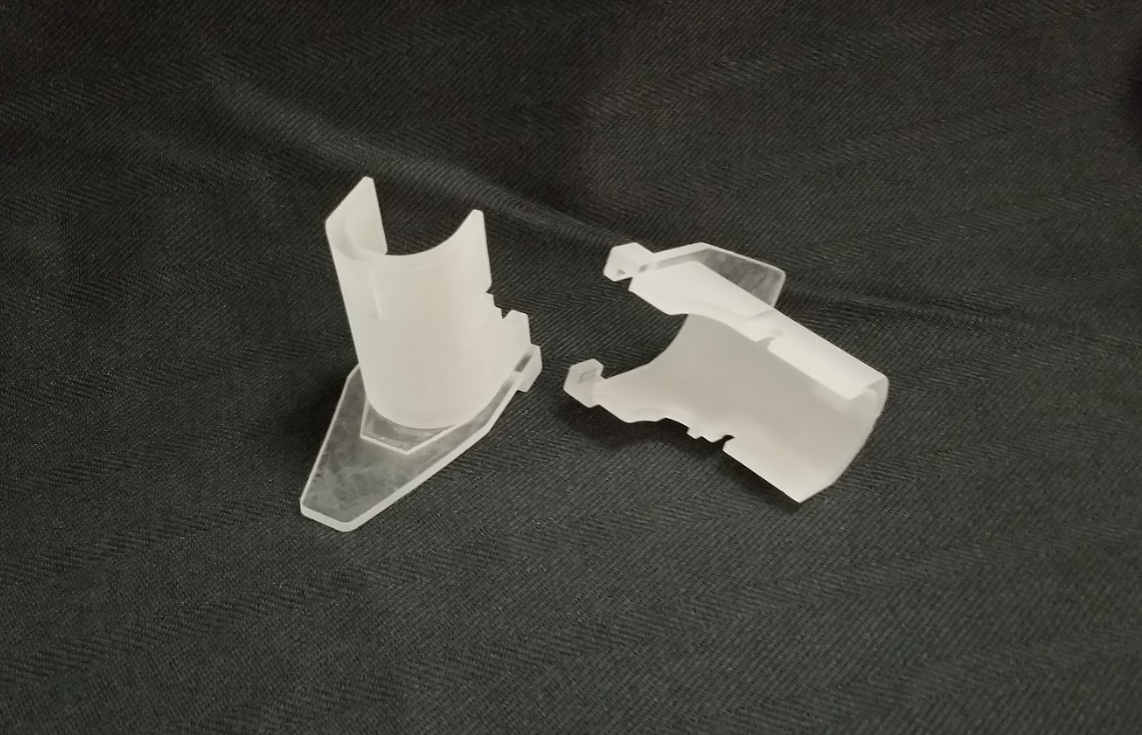

Technology: Multijet Modeling

Max Build: 294 x 211 x 144 mm (11.6 x 8.3 x 5.6 in)

Materials:

-

Acrylic Plastic: Visijet White & Clear

-

Polypropylene/ABS-Like: Visjet Armor

Medical Device Parts – Projet Visijet Armor

3D printing is a cost effective method to analyze your part designs before committing to the high cost of tooling development or the machining of production parts. NeoMetrix utilizes MultiJet, PolyJet, CFF, FDM, SLS and SLA technologies for 3D printing. Our 3D printers can produce parts in a variety of different photopolymer materials. Ultra fine layer thickness create accurate, clean, smooth and highly detailed 3-dimensional models for a variety of applications:

- Rapid Prototyping

- Concept Modeling

- Silicone Molding

- Additive Manufacturing

- Rapid Tooling

Let our engineers work with you to determine the best material and process for your project. Whether you’re looking for a quick prototype or a durable, end-use part, we can help!

Get in touch with us to help solve your design challenges!

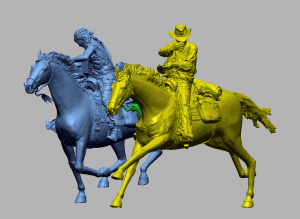

History

- Historical duplicates for display

- Accurate dimensional references

Art/Design

- Prototypes

- Sculptures

Automotive

- Interior/ Exterior parts & accessories

Architecture

- Create models during development process

Fashion & Jewellery

- Rings, earrings, necklace pendants

- Accessories

Medical

- Prosthetics

- Silicone molding for simulations

- Hardware for medical equipment

Food

- Utensil and tools

- FDA Approved Material

Electronics

- ESD Safe materials

- Engineering-grade materials

Firearm

- Components

- Adjustment Tools

Aerospace

- Air ducts, wall panels, seat frameworks, & engine components

Media & Entertainment

- Movie Props

- Replicas

Agriculture

- Replacement parts

- Manufacturing tools

Check Out Our Available 3D Printing Equipment