High-Accuracy Metrology & Reverse Engineering Solutions

Regardless of the industry you may work in, reverse engineering and dimensional inspection of production parts, tools, jigs, assemblies, sub-assemblies or final products are critical in many manufacturing development processes.

The ultimate goal of using 3D scanning techniques is to accomplish automatic in-line inspection of simple & complex parts, as well as assemblies with precision.

With 3D scanning technology, you will be able to discover:

- Loose tolerance structures such as frames, panels, & more

- Reverse Engineering & Non-contact Measurement

- First Article Inspection and Infrequent Statistical Sampling

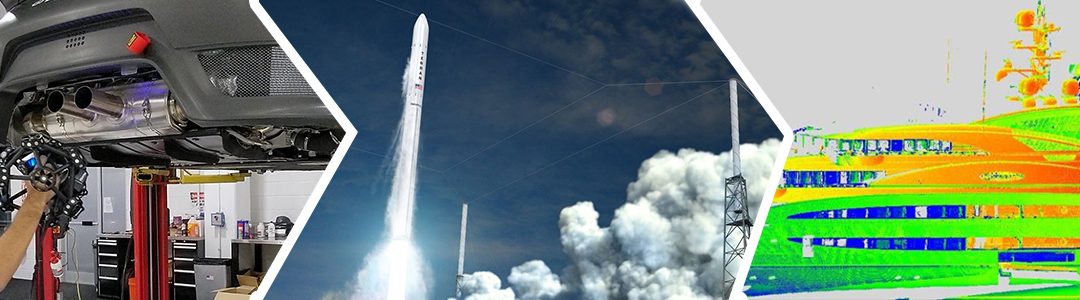

Top 3 Industries & Applications

Aerospace

Aquire 3D scan data without complications, and fast & easy set up. Have the ability to scan large volume measurements with efficiency in a short amount of time.

Automotive

Measure parts with complex surface finishes ranging from freshly machined to dark paint & aquire surface data to create CAD files for producing accurate custom fits.

Marine

Quickly capture accurate surface data from marine vehicles in the most challenging environments: such as on a boat deck, on a trailer, in a parking lot. Reverse engineer or make modifications to create custom parts & accessories!

Why Partner With Us?

Our mission is to partner with our clients by understanding their unique requirements and aid in developing, deploying, and supporting effective solutions. With 20+ experience in these Top 3 Industries we are simply able to present the best solutions possible for any application or project.

Ask us about 3D scanning services and equipment!

Request a Quote or Speak with an Expert