A collaborative team of researchers from Khalifa University, Kingston University, and the University of Liverpool have leveraged the unique capabilities of additive manufacturing— 3D Printing—to design ultra-strong, lightweight and functional components that will make the structures of unmanned aerial vehicles (UAVs) significantly lighter and stronger, allowing for advanced applications.

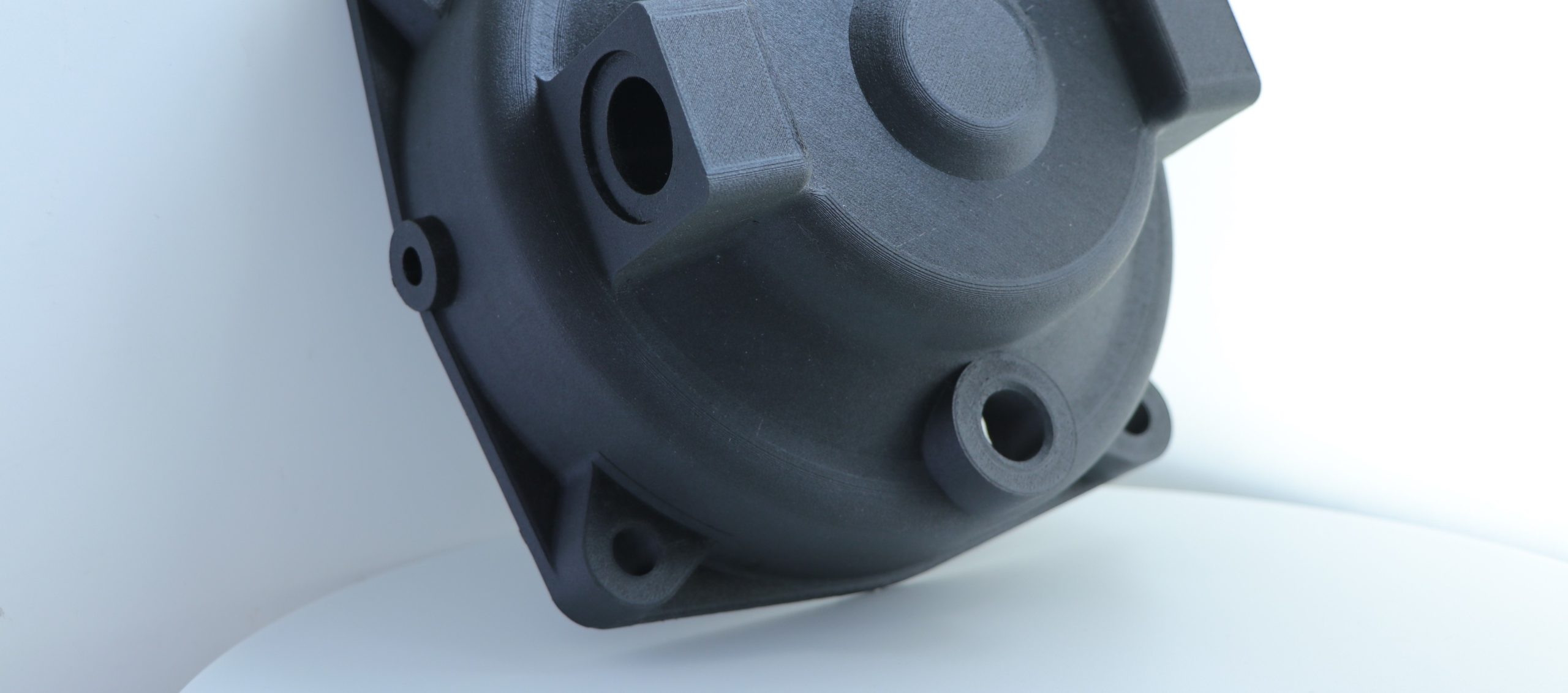

KU’s research team, led by Associate Professor of Aerospace Engineering Dr. Yahya Hashem Abdallah Zweiri, was able to increase the mechanical strength of 3D printed plastic parts by 1600% through a sandwich-structured composite solution and reduce the weight of 3D printed drone structures by 50% through topology infill optimization methods, which optimize the material layout within its design space and its interior structure. Results will support the advancement of the UAE’s national innovation goals, specifically in the targeted area of autonomous transportation, which is identified by the UAE Economic Vision 2030 as a key area of focus.

Traditional manufacturing methods produced drones that, despite being dense and heavy, had relatively low tensile strength, making them brittle. This limited the potential application of drones for industrial and research purposes in military, agricultural, search and rescue, telecommunications, transportation, topography, mapping, and surveillance, where robust UAVs play unique roles with varied hardware and electronics.

Typically the methods to improve the structural integrity of 3D printed plastics such as resin filling, ultrasonic strengthening, and infrared laser heating, have only been able to improve the strength of printed parts by 45%, 22%, and 50%, respectively. However, these improvements are incremental advancements compared to the results achieved by KU researchers through use of the sandwich-structured composite solution and topology infill optimization methods.

General Atomics MQ-1 Predator, an advanced UAV in flight.

“Our focus has been to retain the advantages of 3D printing, which enables rapid manufacturing of complex geometries, and applying simple post-processing steps to make 3D-printed drones far more resilient, lighter, and therefore more useful for local industry and research purposes. To reduce the weight, we developed a unique topology and infill optimization method that employs unique geometries to create lighter, porous structures,” said Dr. Zweiri.

Less dense core material will inevitably lead to weaker components and structures, which by itself doesn’t improve the efficacy of drone technology. However, when combined with CFRP laminates, the structure is not only lighter but significantly stronger.

By reducing the weight and simultaneously increasing the strength of 3D printed components, KU’s research collaboration has enabled drones to increase flight-time through use of larger batteries, collect more data through more complex sensors, and perform more specialized tasks with heavier hardware.

Drone technology has improved drastically over the past decade with numerous improvements in electronics, computer processing, production methods, and core materials. Based on a Wohlers Associates report, the estimated global market for 3D printing was more than USD5.1 billion in 2015, with a corporate annual growth rate of more than 25.9%. As technological advancements in 3D printing drives cost down and improve efficiencies, the market is expected to grow to USD21 billion by 2020.

Beyond use in UAVs, the contributions of Dr. Zweiri’s team and collaborating researchers have many practical applications in other fields of research and industries. The lightweight and strong structures they developed through synergy between CFRP and 3D printed material, are noncorrosive and thus have wide ranging utility in space, robotics, and biomedical research. His research is expected to further the advancement of 3D printing, autonomous transportation, and synthetic materials manufacturing while contributing to the UAE’s innovative knowledge economy.

Original Article : http://3dprinting.einnews.com/article/477948546/7EbNSLs5f6eJNP5Y