The automotive and motorsport industries operate under unique pressure: win today, innovate tomorrow, and never slow down. Whether it’s a carbon-fiber air duct on a hypercar or a precision jig for a Formula 1 engine, manufacturers are expected to deliver flawless components at record speeds—all while navigating material shortages, supply-chain unpredictability, and stricter design tolerances.

Across the global industry, four manufacturing factors now dictate whether a company can keep up:

1. Advanced Materials & Thermal Performance

2. Design Freedom & Iterative Agility

3. Production Speed & Workflow Efficiency

4. Cost Control & Supply Independence

These four pillars are pushing manufacturers—OEMs and suppliers alike—to rethink how they engineer tools, prototypes, and even end-use components. Increasingly, the solution lies in industrial additive manufacturing, and one particular success story illustrates exactly why.

CASE STUDY

Founded in 1997, MCT Engineering has become a powerhouse in British carbon-fiber manufacturing, producing components for industry titans such as Aston Martin, BMW, Cosworth, JLR, McLaren, and Mercedes-Benz.

From engine assemblies to body panels for hypercars and F1 vehicles, their work demands:

-

aerodynamic precision,

-

controlled surface finish,

-

high-temp resistance, and

-

rapid prototyping + tooling cycles.

The Challenge: Material Control + Speed

Before adopting additive, MCT relied on external partners for 3D printing—creating delays, higher costs, and limited design flexibility. They needed:

-

better control of materials (e.g., PEEK, PEI 1010, reinforced polymers)

-

more consistent tooling accuracy

-

faster turnaround for carbon-fiber lay-up

-

independence from outside vendors

The Search & Solution

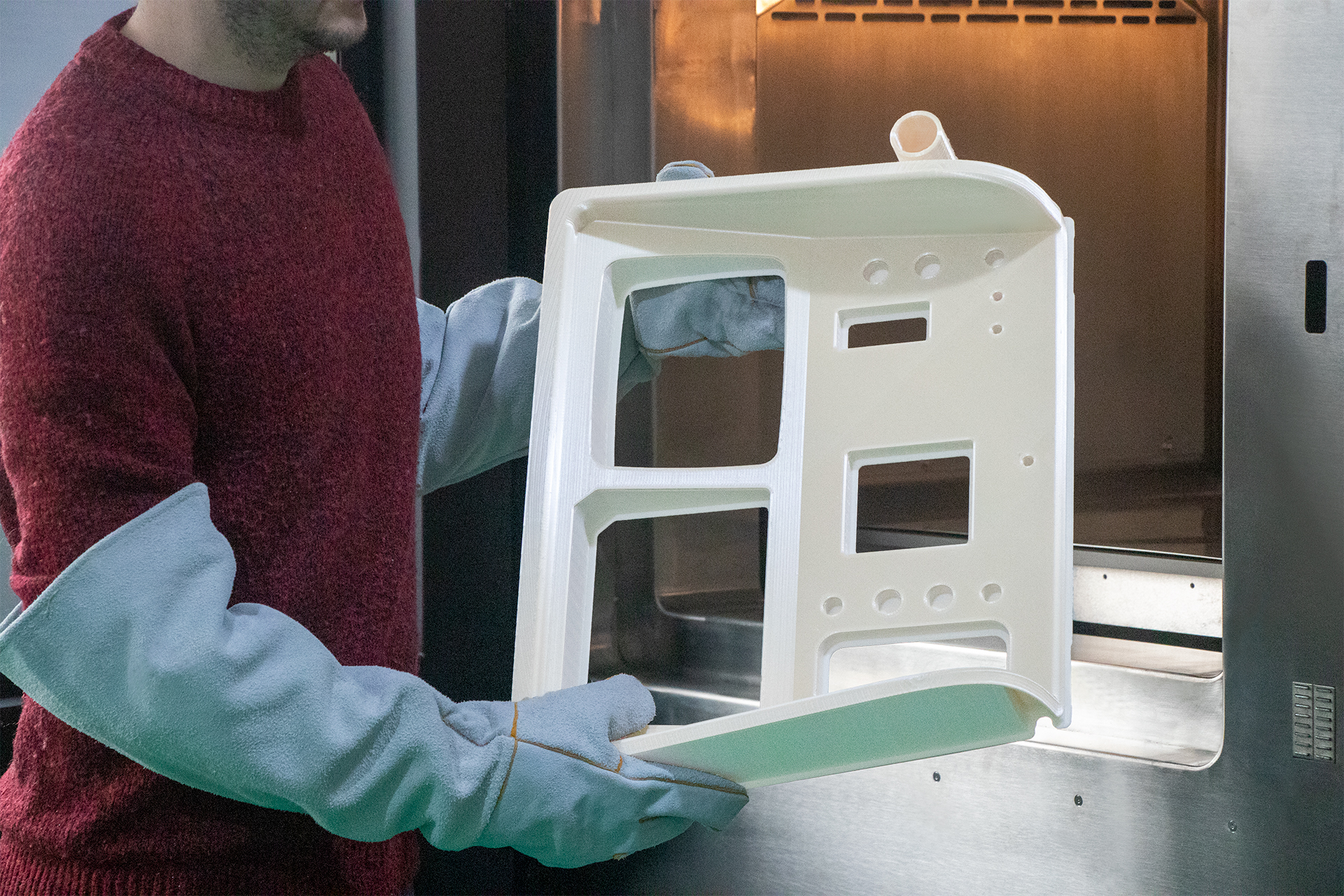

After structured testing—including heat-deflection, shrinkage evaluation, and autoclave cycles at 130–150°C—MCT selected the INTAMSYS FUNMAT PRO 610HT.

Why?

-

High-temperature industrial chamber

-

Large build area

-

Outstanding dimensional accuracy

-

Fully open-material system

-

Compatibility with key automotive materials:

-

PEEK & CF-PEEK

-

PEI 1010 / 9085

-

Nylon + CF blends

-

Engineering-grade composites

-

The Results: Additive at Full Production Scale

MCT integrated the FUNMAT PRO 610HT across engineering, R&D, and composite tooling.

Now, they print:

-

high-precision jigs & fixtures

-

autoclave-resistant molds

-

extractable cores for carbon-fiber ducts

-

rapid tooling and low-volume production parts

Production cycles dropped from days → hours, costs decreased by removing outsourcing, and surface quality matched the demands of elite motorsport programs.

This shift helped move MCT from “test phase” to full additive adoption—a direct example of how the 4 critical manufacturing factors play out in real-world performance environments.

The 4 Key Factors in Automotive & Motorsport Manufacturing – and How Additive Manufacturing Addresses Them

1️⃣ Advanced Materials & Thermal Performance

Modern automotive components—especially carbon-fiber tools and under-hood parts—must endure:

-

high temperatures

-

repeated loads

-

chemical exposure

-

pressure & vacuum cycles

Materials like PEEK, PEI 1010, carbon-fiber reinforced nylons, and PPSU are now essential.

Industrial systems like the INTAMSYS FUNMAT PRO 610HT give engineers access to all of the above—without vendor lock-in.

NeoMetrix Advantage:

NeoMetrix provides material guidance, test prints, and engineering support to ensure the right polymer is selected for the right application.

2️⃣ Design Freedom & Iterative Agility

Aerodynamic components change constantly. Motorsport programs demand:

-

rapid iteration

-

customizable geometry

-

small internal features

-

smooth duct transitions

Traditional methods—wet layup, machined aluminum tools, outsourced molds—slow progress.

With additive, teams can iterate overnight, not weeks later.

INTAMSYS Tools for Design Agility:

-

FUNMAT PRO 610HT → large, high-temp functional tools

-

FUNMAT PRO 310 NEO → engineering-grade desktop machine for smaller fixturing, brackets, housings

Integrating these 3d printing systems with reverse engineering or product developmetn cycles, it takes you to another step closer to forming a full production ecosystem.

3️⃣ Production Speed & Workflow Efficiency

In motorsport, slow production loses races.

3D printing accelerates:

-

tooling

-

validation

-

prototyping

-

low-volume production

-

carbon-fiber lay-up molds

MCT saw parts that once took a week now produced in under 24 hours—with many small molds printed in 8 hours.

NeoMetrix Benefit:

From installation to training, NeoMetrix helps teams optimize print queues, refine toolpaths, and boost throughput.

4️⃣ Cost Control & Supply Independence

Materials, outsourcing, and CNC machining costs continue to rise.

Additive provides:

-

fully in-house production

-

lower tooling costs

-

reduced reliance on external vendors

-

predictable timelines

-

minimized scrap and rework

The open-material system of INTAMSYS is especially valuable—teams can source affordable, high-performance polymers from multiple suppliers.

NeoMetrix Financing:

Easy financing options through NeoMetrix make industrial solutions accessible—even for smaller suppliers and race teams.

🏆 Why Automotive Manufacturers Choose INTAMSYS + NeoMetrix

✔ High-temp industrial additive manufacturing

✔ Large-format production tooling

✔ Desktop-sized engineering machines for daily operations

✔ World-class materials for motorsport environments

✔ Easy financing + full training + integration support

✔ Proven results (MCT Engineering, McLaren suppliers, composite teams)

Conclusion: Additive Manufacturing Is the New Competitive Edge

The four factors—materials, design freedom, speed, and cost control—define which automotive teams continue to innovate and which fall behind.

MCT Engineering’s success is proof: when industrial additive becomes part of your production ecosystem, you unlock new speed, flexibility, and capability.

With solutions like the INTAMSYS FUNMAT PRO 610HT and FUNMAT PRO 310 NEO, supported by NeoMetrix’s training, service, and financing, high-performance manufacturing teams can:

-

shorten lead times

-

reduce production costs

-

achieve higher accuracy

-

streamline carbon-fiber workflows

-

expand material capabilities

Additive isn’t just a tool—it’s a competitive advantage.

NeoMetrix helps deliver it.