When it comes to farm equipment, there are few companies that can match the expertise of French-based MAILLEUX. For over 50 years now this family business has been designing and manufacturing parts/devices for all types on tractors from tiny garden models up through large commercial units with high power needs – making them a worldwide leader in their field!

Among other things, MX possesses expertise in designing brackets (to fit loading arms) for all farm tractors on the market, as well as in developing steering systems for its loaders.

Get Started Today!

THE PROBLEM

The process of obtaining 3D models for tractors can be difficult, but it is essential in order to develop and manufacture equipment parts like MX does with loading arms. As such they must take measurements on all available types so that their designs will function properly when fitted out onto these different makes/models of vehicles without fail. These measurements are needed in order to obtain a 3D model for each tractor to pursuit future designs.

In an attempt to shorten the measurement time and curb the related costs, the Technical Service started looking for an alternative solution, one that could be faster as well as more flexible, and which measurements would be precise and reliable, regardless of the measurement environment conditions.

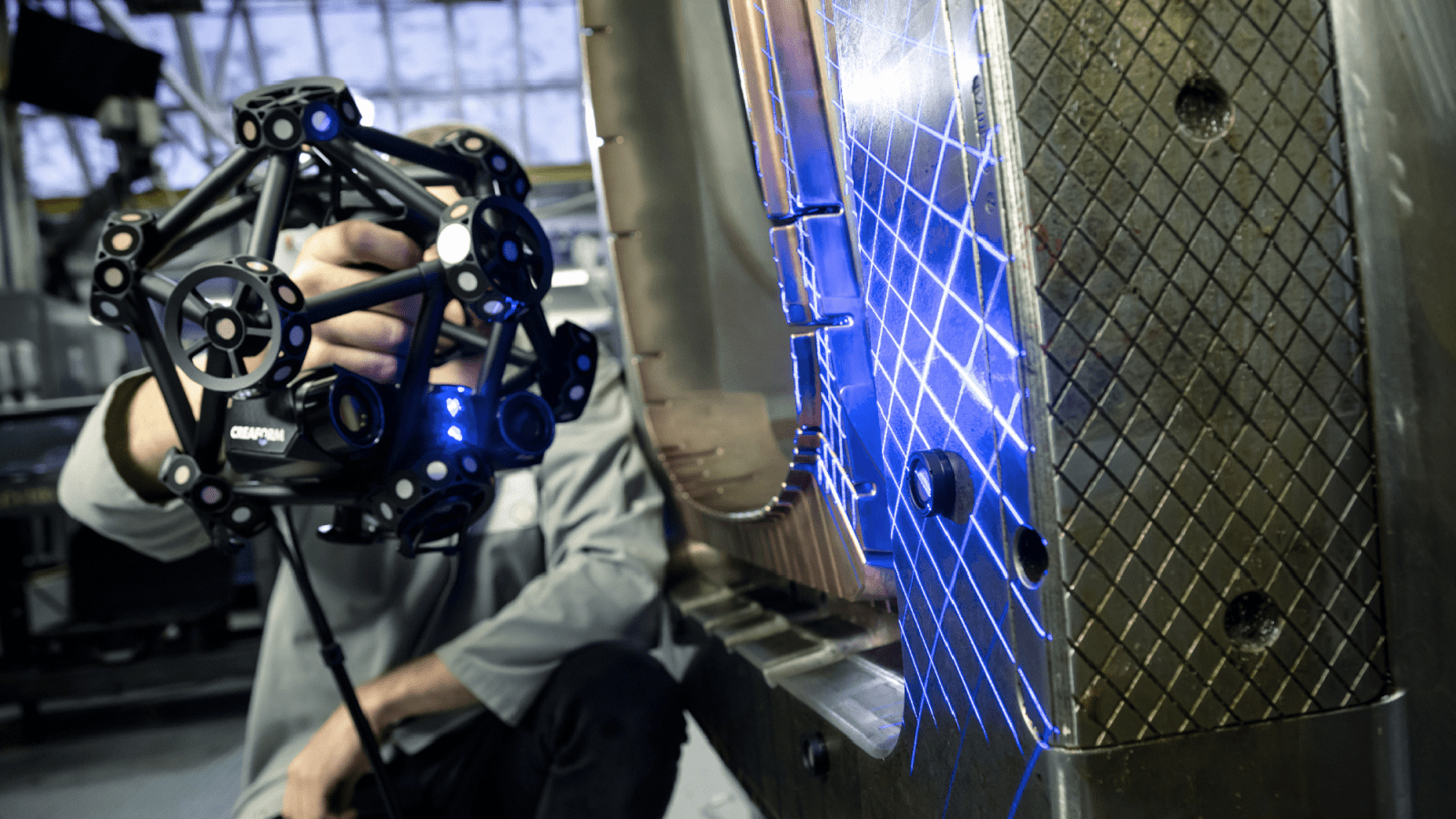

The discovery of Creaform’s portable 3D technologies and how it can be used to improve company production was during the MesurExpoVision trade show. The technology offered by TRUaccuracy with dynamic measurement features exclusive for both their HandyPROBE CMM scanner, as well as some new innovative products from this manufacturer are what made them realize just what benefits these could bring in terms cutting down time spent on certain tasks while still ensuring high precision measurements without any errors or mistakes occurring along the way!

On top of being completely insensitive to vibrations and movement in their surroundings, the Creaform measurement systems operate within a measurement volume that can be easily and dynamically enlarged without the need for leapfrogging or planing. This was an undisputable advantage for MX, since it could completely eliminate the following steps : moving the arm (to measure the whole tractor), calibrating, and planinng.

Technological Integration into the Workflow

MX’s new solution involving the Creaform MetraSCAN Black| Elite enables them to measure the entire tractor model with pinpoint accuracy in an extremely short amount of time. This makes it possible for technicians who work fast-paced jobs like farming or construction where time is money; they can now finish their tasks much quicker than before without having have move bulky equipment around on site each day before starting work!

In the fall of 2012, the company purchased a Creaform’s scanning and probing system, including a HandyPROBE portable CMM, a MetraSCAN 3D optical CMM scanner, a C-Track 780 dual-camera sensor, along with the Geomagic Solutions post-treatment software from 3D Systems. Nowadays, MX uses Creaform technologies to digitize its tractors: scanning all the areas needed to design the adapted structures, including the bracket mounting points and their environment (tractor cabs, exhaust pipe, gas tank, battery box, filters, pipes, radiator, engine and motor belt pulley). The surfaces are processed, cut, and cleaned with Geomagic Solutions, then exported to CAD in .stl format.

Furthermore, integrating these portable 3D measurement technologies from Creaform enabled MX to set up a flexible measurement system that can be used by 6 different resources at the design office.

Measurement Speed = Faster Work Volume

Mr. Emmanuel Renoux, R&D director at MX, explains how the Creaform technologies helped the company. “This system enabled us to shorten our measurement time by more than half. Because of that time-saving, we can measure a greater number of tractors, which in turn makes it possible for us to offer a wider choice for our customers, and have a more competitive time-to-market. Our goal is to go from about 50 projects a year to roughly 100 when we “reach full speed,” so to speak. This new equipment additionally makes our work quicker and easier when we need to take measurements externally, whether in France or abroad”.

“Had we not invested in this equipment, we would not have been able to keep up with the pace, since new tractors keep arriving on the market at an increasingly fast speed, as manufacturers offer more and more different variations in order to better answer their customers’ (farmers) needs. Since we are now better equipped to measure these tractors, we even reinforced our design teams in order to optimize and benefit from all this data,” added Mr. Lenoux.

Original Article: https://www.creaform3d.com/blog/success-stories/when-pace-picks/

Ask us about 3D scanning services and equipment!