Duisburger Modellfabrik GmbH is well-known for their large foundry patterns that are made of wood, plastic block materials and foam. They produce these items in steel or gray iron castings to manufacture steam turbines engine beds diesel engines components among other things for various industries such as energy production (turbines) construction equipment manufacturing – especially heavy duty trucks & buses; transportation modes including ships tanks cars trains planes etc.

With the increase in customer demand for comparing model equipment with original CAD data, a new trend has emerged: Computer Aided Inspection. The practice consists of capturing, comparing, and analyzing scan data of original parts or prototypes to CAD Models.

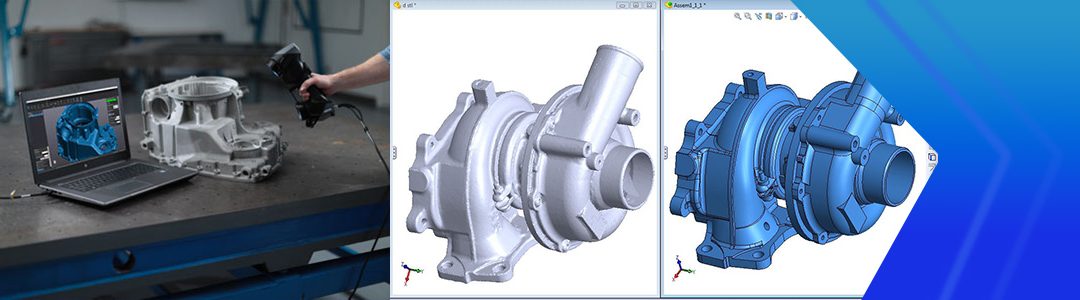

Implementation of the 3D Scanner & Inspection Software

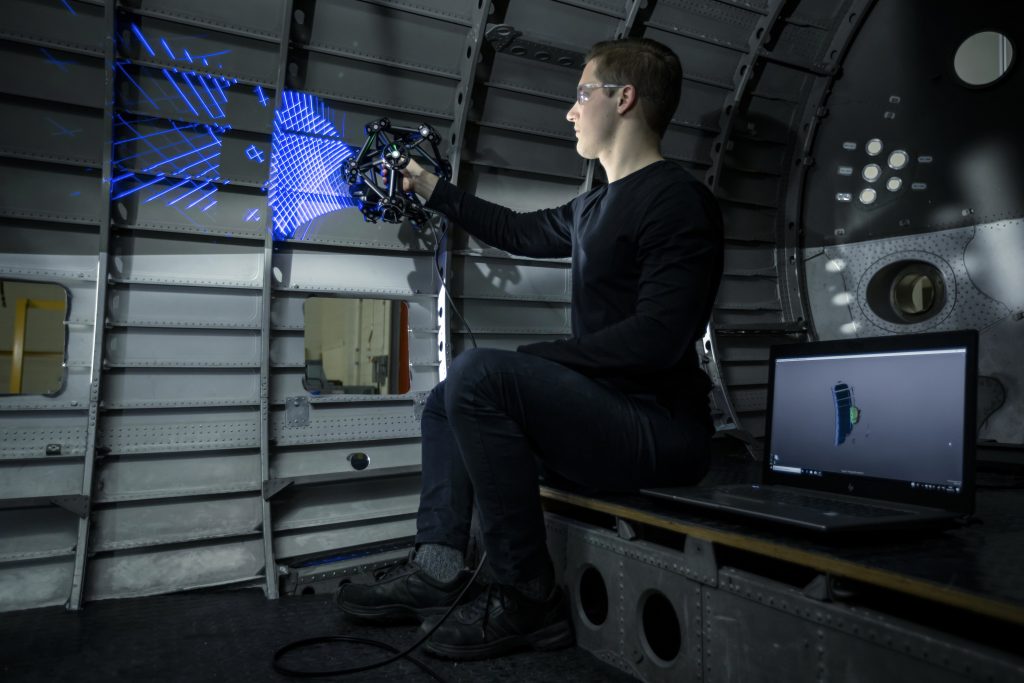

The decision was soon made to purchase their own measuring system in order to reduce costs and avoid frictional losses between model builder and surveyor. Since the company manufactures components of several meters in length, width and height, it was important to find a 3D measuring system that could scan large surfaces quickly and easily. Of course, not at the expense of accuracy. They were also looking for a system that is portable so that in can be used in just about ANY environment.

They settled on Creaform’s MetraSCAN 3D Scanner, an optical CMM scanner specifically designed for high-precision and repeatable metrology-quality measurements and 3D geometric surface inspection in manufacturing. The decisive factors were the flexibility of the scanner, the ability to digitize undercuts, and the possibility of virtual assembly.

Rapidly inspect even the most complex parts using 3D scanned data and Geomagic Control X.

- Overlay the scans directly on to your 3D CAD model for ANALYSIS and COMPARISON

- Generate 3D Color Maps to show overall surface deviations

- Dimension geometric features in 2D and 3D

- Automatically output results in easy to read graphical reports

With the introduction of 3D scanning, Duisburger Modellfabrik can now offer a service that is more cost effective and efficient. components are completed with less labor hours so they will be ready for shipment faster while also having better quality control because all finished products come directly from their scans in one place instead going through several providers like before.

Ask us about 3D scanning services and equipment!