Medical 3D printing applications have dramatically improved accessibility to healthcare devices in recent years.

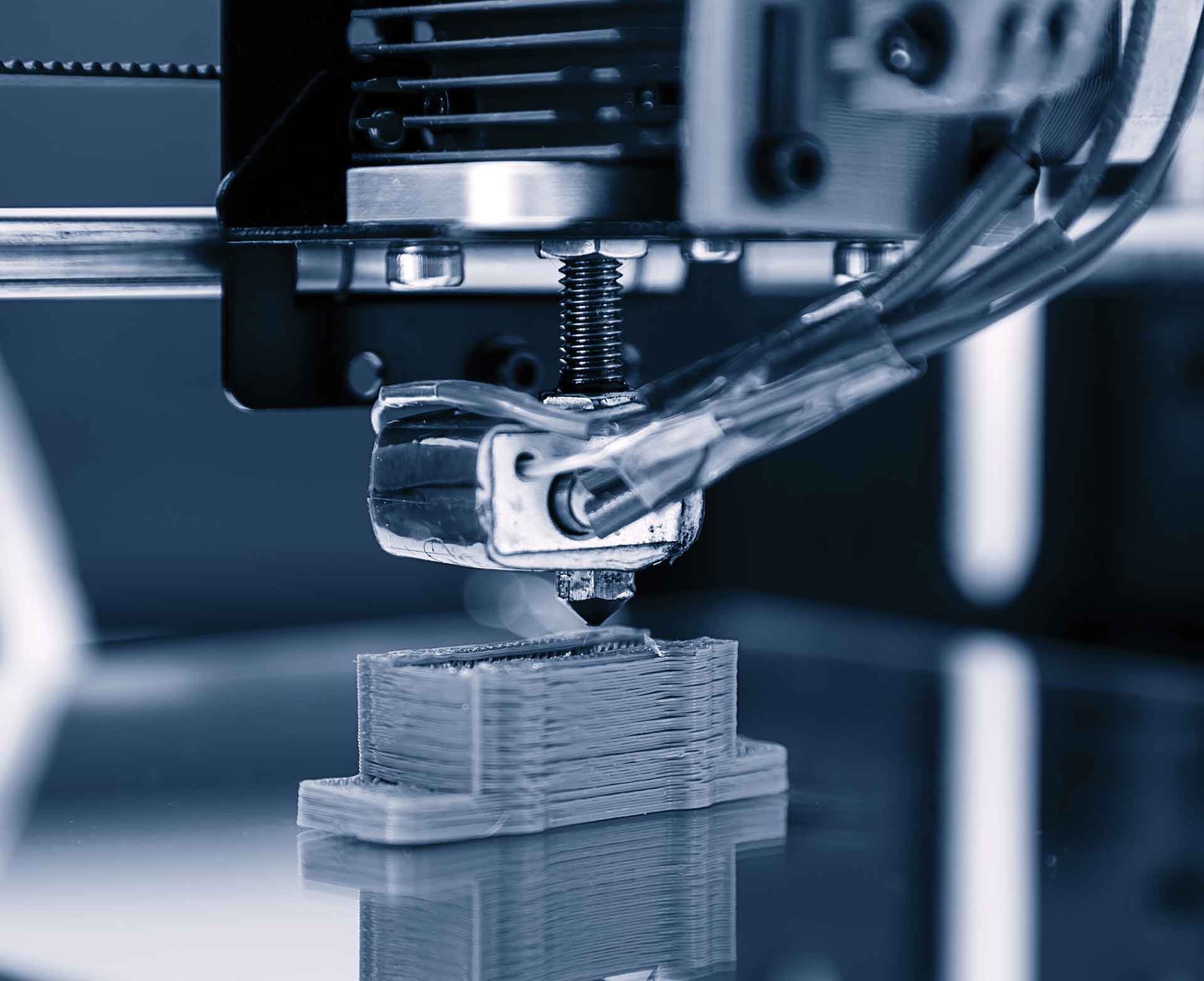

3D Printed prosthetics have made the devices more affordable, accessible, and effective with on-demand personalized manufacturing. But since accessible 3D printing has been largely secluded to desktop additive manufacturing systems, larger full-body medical devices and mobility aids haven’t, until now, received the same attention in the medical-industrial revolution.

Today, as large-format 3D printing has become increasingly accessible and reliable, the medical industry is making up for lost time. This past year has seen some incredible innovation in medical 3d printing made possible by large-format additive manufacturing with BigRep technology.

Two of BigRep’s partners, Phoenix Instinct and 3Dit Medical, have proven especially noteworthy, having created inspiring innovations and earned the support they need to fully realize their life-changing designs.

Medical 3D Printing allows for a smart Wheelchair

The wheelchair has remained largely unchanged since the 1980s, said Andrew Slorance, CEO of Phoenix Instinct and a wheelchair user himself. “Wheelchair companies have been unable to stop thinking mechanical,” he says. “All the products around us are evolving – becoming smart. It doesn’t make any sense.”

The wheelchair has remained largely unchanged since the 1980s, said Andrew Slorance, CEO of Phoenix Instinct and a wheelchair user himself. “Wheelchair companies have been unable to stop thinking mechanical,” he says. “All the products around us are evolving – becoming smart. It doesn’t make any sense.”

With a vision to reinvent wheelchairs with smart technology, Slorance and Phoenix Instinct entered the Toyota Mobility Ultimate Challenge: a fund supporting the development of innovative mobility solutions worldwide. In the 18-month competition timeline, the company developed the Phoenix i: a revolutionary wheelchair with a smart center of gravity.

The Phoenix i is an ultra-lightweight carbon-fiber wheelchair with a unique smart weight distribution technology. The chair continually adjusts its center of gravity with user movements, making it easier to control in varied movement, terrain, and contexts while decreasing risks like backward falls. Other smart features like lightweight power assist and automatic breaking make inclines easier to traverse and eliminate most need for physical hand breaking.

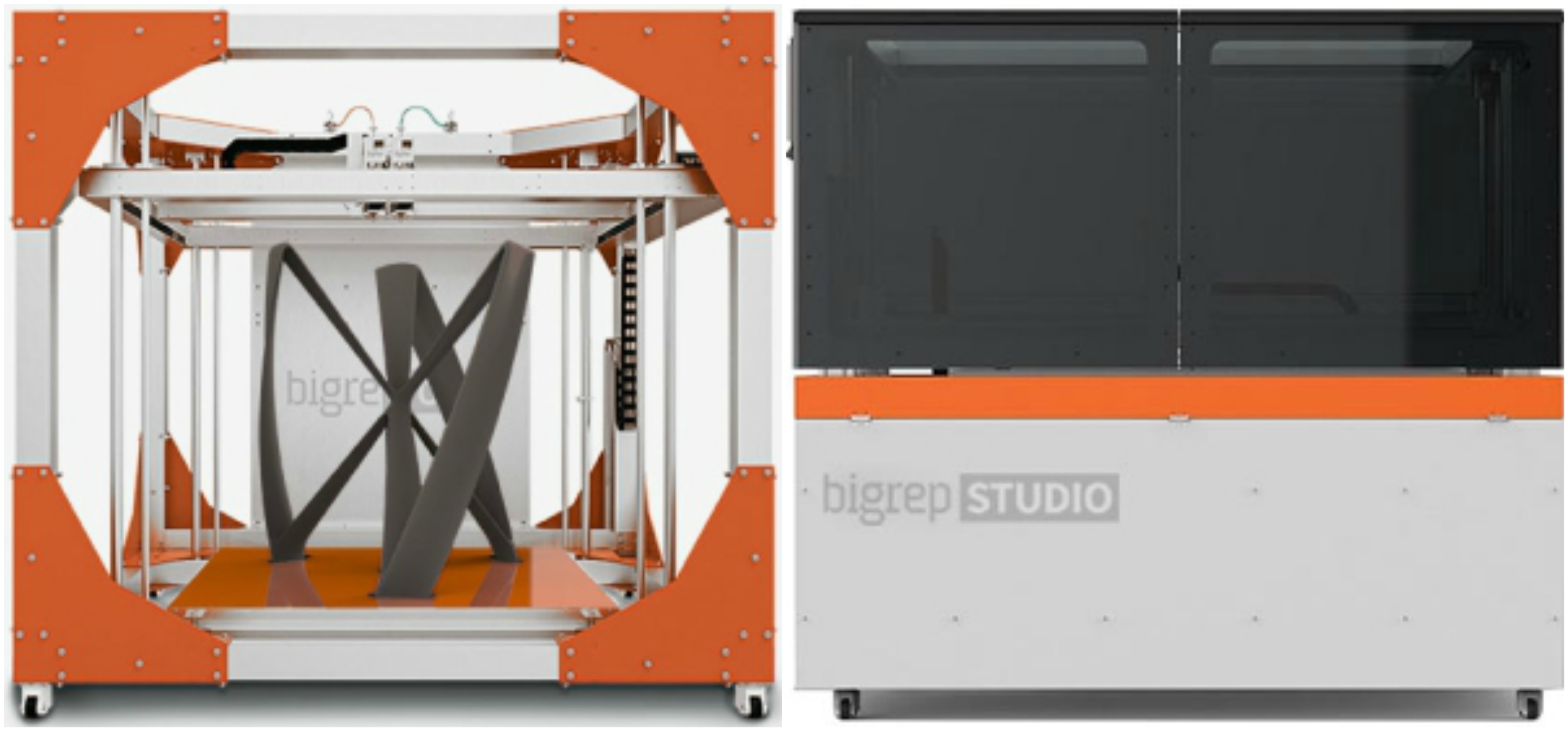

The company’s BigRep large-format 3D printer made developing the chair in Toyota’s timeline possible, said Slorance. They reiterated constantly, printing full-scale frames to test on site – an accomplishment that simply wouldn’t be possible with traditional workflows. “My last carbon-fiber chair took about 4 years to develop,” he said. “We’re printing full sized wheelchair frames. It’s transformed the ability to develop a product.”

Now that the company has finished initial prototyping, they’re continuing to use their BigRep by 3D printing carbon fiber moulds used in manufacturing the chairs. There’s another 18 months of development to go, says Slorance, but with the million-dollar development fund the company won from the Toyota Mobility Ultimate Challenge and modern industrial resources like their BigRep industrial 3D printer, the future is bright for the Phoenix i.

3D Printing Prosthetics of personalised Scoliosis Braces

Scoliosis affects approximately 3% of the world population, which means there are about 1 million scoliosis patients in Saudi Arabia, according to Dr. Ahmad Basalah, Vice President of 3Dit Corp.

Scoliosis affects approximately 3% of the world population, which means there are about 1 million scoliosis patients in Saudi Arabia, according to Dr. Ahmad Basalah, Vice President of 3Dit Corp.

Halting spinal degradation in scoliosis patients requires individually personalized body braces that are tremendously expensive and difficult to produce. But now 3Dit Medical – 3Dit Corp.’s medical arm – say they’ve found a new solution to not only build braces that halt spinal degradation but also show promising results in spinal correction.

With their BigRep ONE’s cubic-meter build volume, 3Dit Medical has already successfully 3D printed scoliosis body braces that show promising results in spinal correction. The braces are already 50% lighter than their traditional counterparts, cost a fraction, and are created in just three days instead of the previous three weeks. But thanks to the digital nature of additive manufacturing, they also allow for simple adjustments before printing that will apply pressure to precise points and help slowly correct a wearer’s spine.

“The practice of making a conventional scoliosis brace is humiliating,” says Dr. Wesam Alsabban, President of 3Dit Corp., as he described the process of measuring scoliosis patients which, before 3D printers, required them to hang naked from a ceiling while measurements are taken.

With 3Dit Medical’s new additive manufacturing process, patients only require a simple x-ray and 3D scan to gather measurements.

The groundbreaking application won third place in Saudi Arabia’s MIT Enterprise Forum. Excited by the potential, 3Dit Medical says they’ll continue developing the technology and think it will lead to even more valuable products in the future.

How could you change the world with an industrial 3D printer to streamline innovation and production?

Original Source: https://bigrep.com/posts/medical-3d-printing-prosthetics/