Check out this article to get an overview of 3D printing materials and their average costs today.

A Quick Introduction

3D printing materials are separated into several categories, which relate to the three most popular 3D printing technologies:

- Fused deposition modeling (FDM),

- Stereolithography (SLA)

- Selective laser sintering (SLS)

Each of these are unique in it’s own way. The materials for each technology need to be a different form. Currently, there are a number of materials and techniques of 3D printing that are available. Instead of covering each type of 3D printing material, let’s look at the different categories of materials and their costs.

The most two most basic categories are polymers and metals, where both have their own sub-categories.

Polymers, for example, can be further divided into thermoplastics and thermosets which we’ll discuss using more detail in the following paragraphs.

The metals category is far less complex than polymers. In the metals category there aren’t that many materials, mostly metal powders used with metal powder fusion 3D printing technologies.

Thermoplastics: Filaments and Powders

Polymers are literally everywhere around us, from shopping bags to car parts to children’s toys. In 3D printing, thermoplastics can be divided into 2 categories: thermoplastics and thermosets. The difference between the two comes down to how they behave when exposed to high temperatures.

Arguably the more important of the two, thermoplastics can be heated and solidified multiple times without losing their physical and chemical properties. This is part of the reason, for example, that PLA filament prints can easily be recycled.

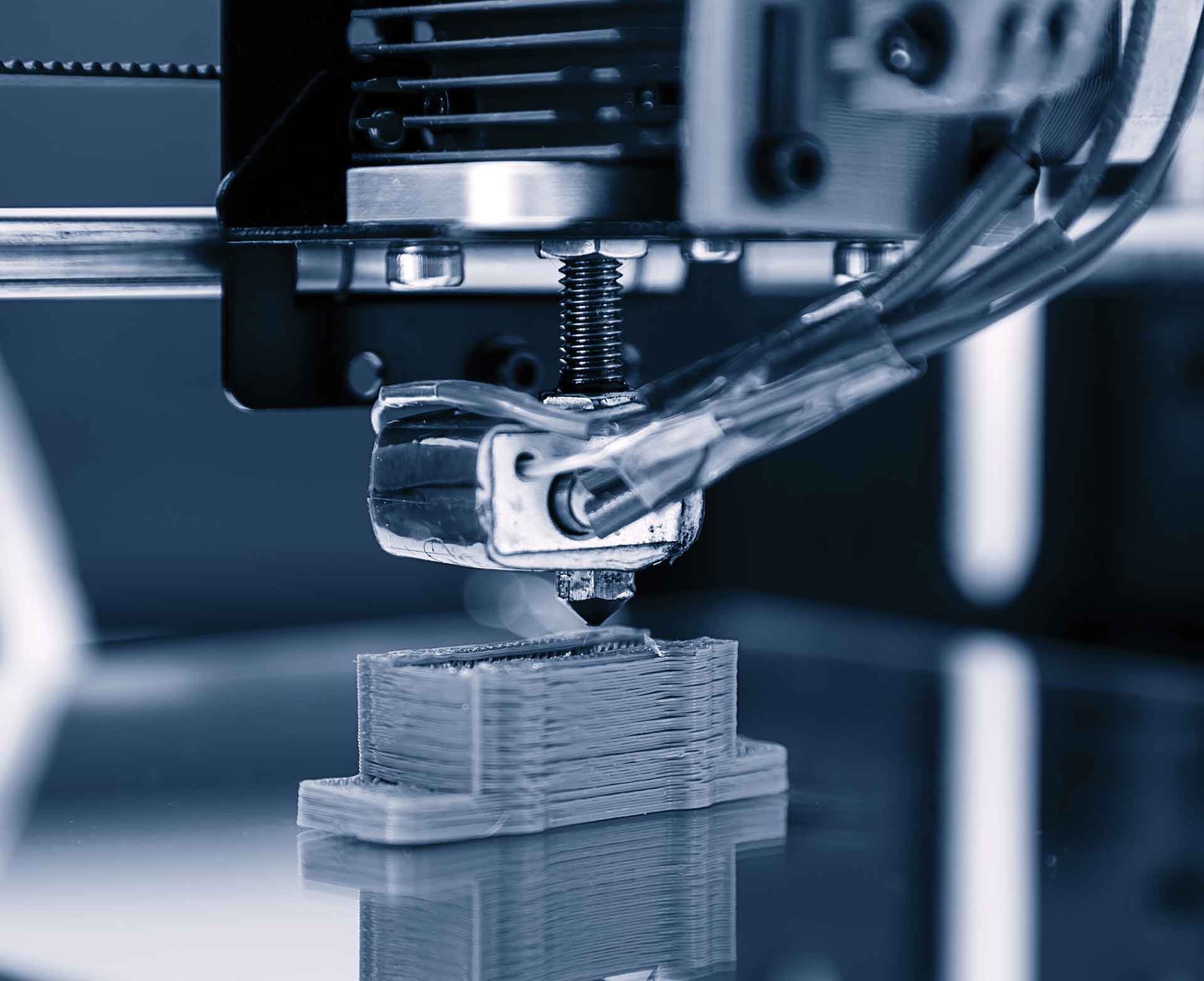

3D printing materials that come in the form of filaments or powders are thermoplastics.

Resins, which we’ll look at in the next section, are thermosets.

Filaments

There are many types of filaments such, as PLA, ABS, PETG, carbon fiber, wood-like and even flexible materials based on PLA. They all come with a different price tag. Naturally, this makes it hard to answer the question, how much does this 3D printer material cost? Additionally, pricing heavily depends on the quality of the material. Generally speaking, PLA filaments are the cheapest, next are ABS filaments, and then come the rest.

When looking for filaments for home or office 3D printers, expect prices to be in the range of around $20 to $70 per kg. That may seem like a pretty big gap, but as we said, prices highly depend on the type of material, the quality, and the manufacturer.

If you want to save money in the long run, you can buy PLA plastic pellets starting from $10 per kg. This is the raw material PLA filament is made from. In its natural form, it is semi-transparent and can be colored with pigments. The drawback is that you need a special printing system to 3D print the pellets — and this one’s quite expensive.

For applications requiring greater strength than ABS, Markforged offers Onyx, a chopped carbon fiber filled Nylon ($190 per 800 cc spool). Onyx can also be reinforced with continuous fibers such as fiber glass, kevlar and carbon ($150 per 50 cc spool). Parts made from Onyx with continuous carbon fiber reinforcement can approach the strength of 6061 aluminum.

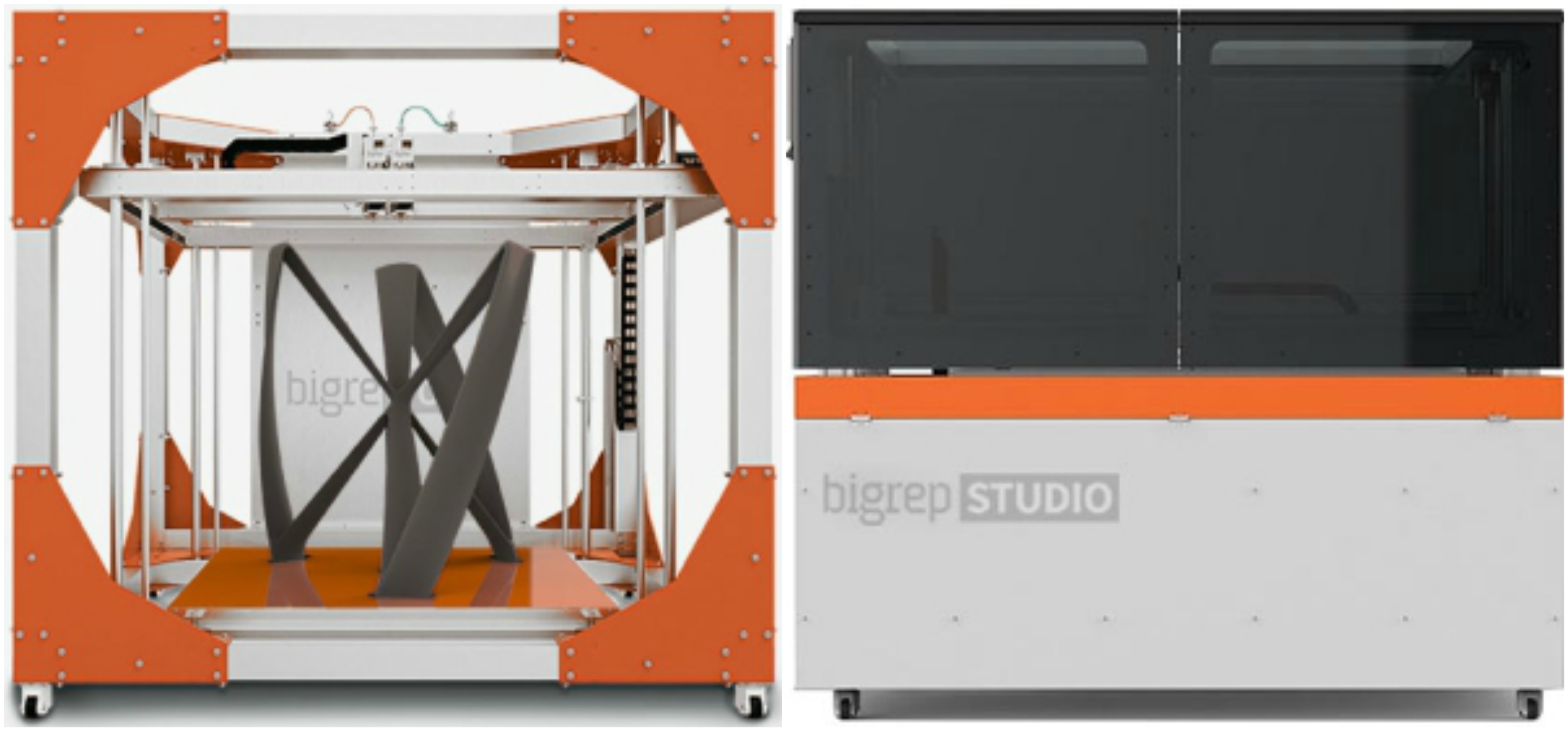

Powders

SLS makes use of polymers in a form of powders. The most used type of polymer powders for SLS is called polyamide, also known as PA. Nylon is the most common type of polyamide.

The standard PA powder for SLS is PA 12 nylon, which costs somewhere between $45 to $75 per kg. Just as with filaments, this is a rough price range for “normal” powders. Naturally, there are more expensive powders that are used by professionals who require superb material appearance and properties.

Unfortunately, it’s difficult to give an example of a standard SLS powder, as they are typically proprietary and vary between 3D printer manufacturers.

As you’ve probably noticed, the 3D printer material cost for SLS is higher than with filaments for FDM. This is one of the main reasons FDM remains the most popular time of 3D printer.

Material Costs

– ProHT (ABS-Like) – $129.95 for 2.5 kg Spool

– PLA – $72.00 – for 2.3 kg spool

Prints using PLA, PETG, Pro HT, TPU, PA6/66

Thermosets: Resins

In terms of price for resins, they are, generally speaking, priced very similarly to standard SLS powders. But as with prices for other types of 3D printing materials, it highly depends on the quality of the material, the type of the material and the manufacturer.

The average 3D printer material cost for standard SLA resins is approximately $50 per liter. That means entry-level, cheap resins may even be under $50.

MakerJuice offers a standard resin for SLA 3D printing, which costs $58 per liter.

For professionals who need the best possible surface finish and special material properties (i.e. dental or ceramic resins), there are more expensive materials, and believe it or not, some can cost as much as $500 per liter!

Prints using 17-4 PH Stainless Steel/ Copper/ H13 Tool Steel/ Inconel 625/ A2 and D2 Tool Steel

Metal Powders

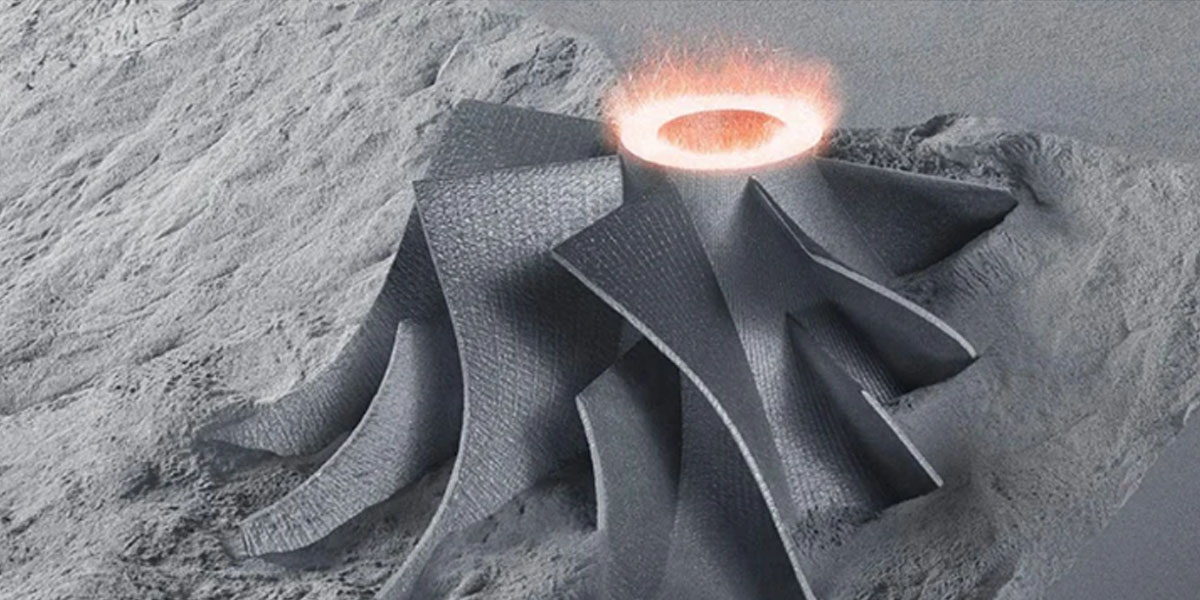

The final 3D printing material which we’ll take a look at is metal powder. When 3D printing metal, the best option is to use powder sintering technologies. The two most popular of these is direct metal laser sintering (DMLS) and selective laser melting (SLM). Both work by heating the material to a point where the particles fuse together, which eventually results in single solid object.

The biggest disadvantage of using metal is the 3D printing material cost. Metal powders are rather expensive; you can expect to pay between $350 and $550 per kg. Keep in mind that the price range given may not be applicable for all kinds of metal powders but it should be adequate for most metal powders on sale today.

Conclusion

It’s very hard to provide a perfect price range for each 3D printing material, but most of the materials you’ll run into will likely fall in the price ranges mentioned above. The cheapest material for 3D printing is, of course, plastic filament. Following that are resins and powders, which are rather similar in terms of prices. And finally, there are metal powders, which are generally the most expensive.

It’s important to optimize your 3D models so that you spend as little material as possible for what you need. In other words, try not to waste material on supports that might have been unnecessary if the part was oriented differently.

If you’re interested in printing with a particular material but don’t have access to it, consider a 3D printing service.

Original Source: https://all3dp.com/2/how-much-do-3d-printer-materials-cost/